Intsimbi yesiko engwevuiqokobhe lokubunjwa ngundongeenkonzo zeunyango lobushushukunye nonyango olungaphezulu.

Ukubunjwa kweqokobheInkqubo ikwabizwa ngokuba yinkqubo yokugalela yentlabathi eqatywe ngaphambili, ukubunjwa kweqokobhe elishushu okanye inkqubo yokugalela engundoqo. Izinto eziphambili zokubumba yintlabathi ye-phenolic resin efakwe ngaphambili, ebiza kakhulu kunesanti eluhlaza kunye nesanti ye-furan resin. Ngaphezu koko, le santi ayinakuphinda isetyenziswe.

I-Furan resin self-ukuqina kwesanti inkqubo yokugalela (inkqubo ye-nobake) isebenzisa i-furan resin egqunywe isanti ukwenza i-mold yokuphosa. Emva kokuxuba isanti yoqobo (okanye isanti ebuyisiweyo), intlaka ye-furan elulwelo kunye ne-catalyst engamanzi ngokulinganayo, kwaye uyigcwalise kwibhokisi engundoqo (okanye kwibhokisi yesanti), kwaye emva koko uyiqinise ukuze iqine ibe ngumbumba okanye i-mold kwibhokisi engundoqo (okanye isanti. ibhokisi) kwiqondo lokushisa. Emva koko i-mold casting okanye i-casting core yaqulunqwa, ebizwa ngokuba yi-self-hardening ebandayo-ibhokisi yokubumba (i-core), okanye indlela yokuziqinisa (core).

Ngenxa yokuba umngundo wenziwe kwiqondo lobushushu begumbi kwaye akukho mfuneko yokufudumeza, ukuziqinisa kwesanti kukwabizwa ngokuba yinkqubo yokuphosa yokubhaka. Indlela yokuziqinisa inokwahlulwa ibe yi-acid-catalyzed furan resin kunye ne-phenolic resin sand self-harding method, i-urethane resin sand self-harding method kunye ne-phenolic monoester self-harding method.

Njengesanti ebopha ibhokisi ebandayo ezenza lukhuni, isanti ye-furan resin yeyona ntlabathi yokuqala kwaye ngoku isetyenziswa kakhulu kwisiseko saseTshayina. Isixa se-resin esongeziweyo kwisanti yokubumba ngokuqhelekileyo yi-0.7% ukuya kwi-1.0%, kwaye isixa se-resin eyongezelelweyo kwisanti engundoqo ngokubanzi yi-0.9% ukuya kwi-1.1%. Umxholo we-aldehyde yasimahla kwi-furan resin ungaphantsi kwe-0.3%, kwaye ezinye iifektri ziye zehla ukuya ngaphantsi kwe-0.1%. Kwiziseko zase-China, isanti ye-furan ye-resin yokuziqinisa ifikelele kwinqanaba lamazwe ngamazwe kungakhathaliseki ukuba yinkqubo yokuvelisa kunye nomgangatho womphezulu we-castings.

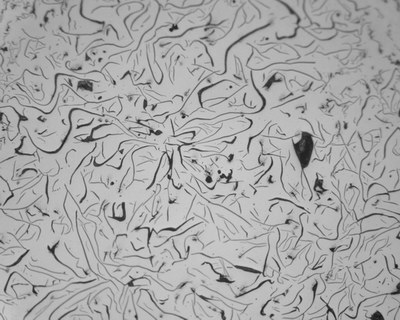

Intsimbi engwevu, okanye intsimbi engwevu, luhlobo lwentsimbi etyhidiweyo ene-graphite microstructure. Ithiywe ngombala ongwevu wokuqhekeka owenzayo. Intsimbi yentsimbi engwevu isetyenziselwa izindlu apho ukuqina kwecandelo kubaluleke kakhulu kunamandla okuqina, njengeebhloko ze-cylinder injini yokutsha yangaphakathi, izindlu zempompo, imizimba yevalvu, iibhokisi zombane, iintsimbi zokubala kunye neentsimbi zokuhombisa. I-iron ekhutshiweyo ephezulu ye-thermal conductivity kunye nomthamo okhethekileyo wentloko zihlala zisetyenziselwa ukwenza i-cookware yentsimbi kunye ne-disc brake rotors.

Ukubunjwa kweekhemikhali eziqhelekileyo ukufumana i-microstructure ye-graphic yi-2.5 ukuya kwi-4.0% yekhabhoni kunye ne-1 ukuya kwi-3% ye-silicon ngesisindo. Igraphite inokuthatha i-6 ukuya kwi-10% yomthamo wentsimbi engwevu. I-silicon ibalulekile ukwenza isinyithi esimpunga ngokuchasene nentsimbi emhlophe, kuba i-silicon yinto yokuzinzisa i-graphite kwi-iron cast, oku kuthetha ukuba inceda i-alloy ivelise i-graphite endaweni ye-carbides yensimbi; kwi-3% ye-silicon phantse akukho khabhoni ebanjwe kwimichiza edibeneyo kunye nentsimbi.

Igraphite ithatha imilo yeflake ene-dimensional ezintathu. Kwimilinganiselo emibini, njengoko ubuso obukhazimlisiweyo buza kubonakala phantsi kwe-microscope, iiflake zegraphite zibonakala njengemigca emihle. Iingcebiso zeeflakes zisebenza njengamanotshi asele ekhona; ngoko ke, ibhityile. Ubukho be graphite flakes benza i-Grey Iron ikwazi ukucatshukiswa lula njengoko zithanda ukuqhekeka ngokulula kwiiflake zegraphite. Intsimbi engwevu ikwanesakhono sokumanzisa kakuhle kakhulu kwaye yiyo loo nto isetyenziswa kakhulu njengesiseko sokunyuswa kwezixhobo zoomatshini.

IiPropati zeMechanical zeGrey Cast Iron | |||||||

| Into ngokwe-DIN EN 1561 | Umlinganiselo | Iyunithi | EN-GJL-150 | EN-GJL-200 | EN-GJL-250 | EN-GJL-300 | EN-GJL-350 |

| EN-JL 1020 | EN-JL 1030 | EN-JL 1040 | EN-JL 1050 | EN-JL 1060 | |||

| Tensile strength | Rm | IMPA | 150-250 | 200-300 | 250-350 | 300-400 | 350-450 |

| 0.1% Amandla eSivuno | Rp0,1 | IMPA | 98-165 | 130-195 | 165-228 | 195-260 | 228-285 |

| Amandla okwandisa | A | % | 0,3 – 0,8 | 0,3 – 0,8 | 0,3 – 0,8 | 0,3 – 0,8 | 0,3 – 0,8 |

| Amandla acinezelayo | σdB | MPa | 600 | 720 | 840 | 960 | 1080 |

| 0,1% Amandla oxinzelelo | σd0,1 | MPa | 195 | 260 | 325 | 390 | 455 |

| Amandla e-Flexural | σbB | MPa | 250 | 290 | 340 | 390 | 490 |

| Schuifspanning | σaB | MPa | 170 | 230 | 290 | 345 | 400 |

| Phungula ucinzelelo | TtB | MPa | 170 | 230 | 290 | 345 | 400 |

| Iimodyuli zokunwebeka | E | GPA | 78 – 103 | 88 – 113 | 103 – 118 | 108 – 137 | 123 – 143 |

| Inombolo yePoisson | v | - | 0,26 | 0,26 | 0,26 | 0,26 | 0,26 |

| Ukuqina kweBrinell | HB | 160-190 | 180 – 220 | 190 – 230 | 200 - 240 | 210 – 250 | |

| I-Ductility | σbW | MPa | 70 | 90 | 120 | 140 | 145 |

| Uxinzelelo kunye nokutshintsha koxinzelelo | σzdW | MPa | 40 | 50 | 60 | 75 | 85 |

| Ukuqhawula Amandla | Klc | N/mm3/2 | 320 | 400 | 480 | 560 | 650 |

| Ukuxinana | g/cm3 | 7,10 | 7,15 | 7,20 | 7,25 | 7,30 | |

IBanga eliLilingana neGrey Cast Iron | ||||||||

| AISI | I-W-stoff | I-DIN | BS | SS | UKUBALULEKILE | UNE / IHA | I-JIS | I-UNI |

| I-A48-20B | 0.6010 | GG-10 | IBanga le-100 | 0110-00 | - | - | FC 100 | G 10 |

| I-A48-25B | 0.6015 | GG-15 | IBanga le-150 | 0115-00 | Ft 15 D | FG 15 | FC 150 | G 15 |

| I-A48-30B | 0.6020 | GG-20 | IBanga lama-200 | 0120-00 | Ft 20 D | FG 20 | FC 200 | G 20 |

| I-A48-40B | 0.6025 | GG-25 | IBanga lama-250 | 0125-00 | Ft 25 D | FG 25 | FC 250 | G 25 |

| I-A48-45B | 0.6030 | GG-30 | Ibanga lama-300 | 0130-00 | Ft 30 D | FG 30 | FC 300 | G 30 |

| I-A48-50B | 0.6035 | GG-35 | Ibanga lama-350 | 0135-00 | Ft 35 D | FG 35 | FC 350 | G 35 |

| I-A48-60B | 0.6040 | GG-40 | IBanga lama-400 | 0140-00 | Ft 40 D | - | FC 40 | - |

| 32510 | GTS-35 | B340/12 | 0815-00 | MN 35-10 | - | FCMW 330 | - | |

| A220-40010 | 0.8145 | GTS-45 | P440/7 | 0852-00 | MN 450 | - | FCMP 440/490 | GMN 45 |

| A220-50005 | 0.8155 | GTS-55-04 | P510/4 | 0854-00 | MP 50-5 | - | FCMP 490 | GMN 55 |

| A220-70003 | 0.8165 | GTS-65-02 | P570/3 | 0856-00 | MN 650-3 | - | FCMP 590 | GMN 65 |

| A220-70003 | - | GTS-65 | P570/3 | 0858 | MN 60-3 | - | FCMP 540 | - |

| A220-80002 | 0.8170 | GTS-70-02 | P690/2 | 0862-00 | MN 700-2 | - | FCMP 690 | GMN 70 |

I-Resin efakwe kwi-Sand Casting Metal kunye ne-alloys | |

| Isinyithi kunye neeAlloys | IBanga elidumileyo |

| Grey Cast Intsimbi | GG10~GG40; GJL-100 ~ GJL-350; |

| Ductile (Nodular) Cast Intsimbi | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| I-Austempered Ductile Iron (ADI) | EN-GJS-800-8, EN-GJS-1000-5, EN-GJS-1200-2 |

| Intsimbi yeCarbon | C20, C25, C30, C45 |

| Intsimbi yentsimbi | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Yenziwe ngentsimbi eshayinayo | I-Ferritic Stainless Steel, i-Martensitic Stainless Steel, i-Austenitic Stainless Steel, i-Precipitation Hardinless Steel, i-Duplex Stainless Steel |

| Iingxube zeAluminiyam | ASTM A356, ASTM A413, ASTM A360 |

| Ubhedu / i-Alloys esekwe kwiCopper | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Umgangatho: ASTM, SAE, AISI, GOST, DIN, EN, ISO, kunye ne-GB | |

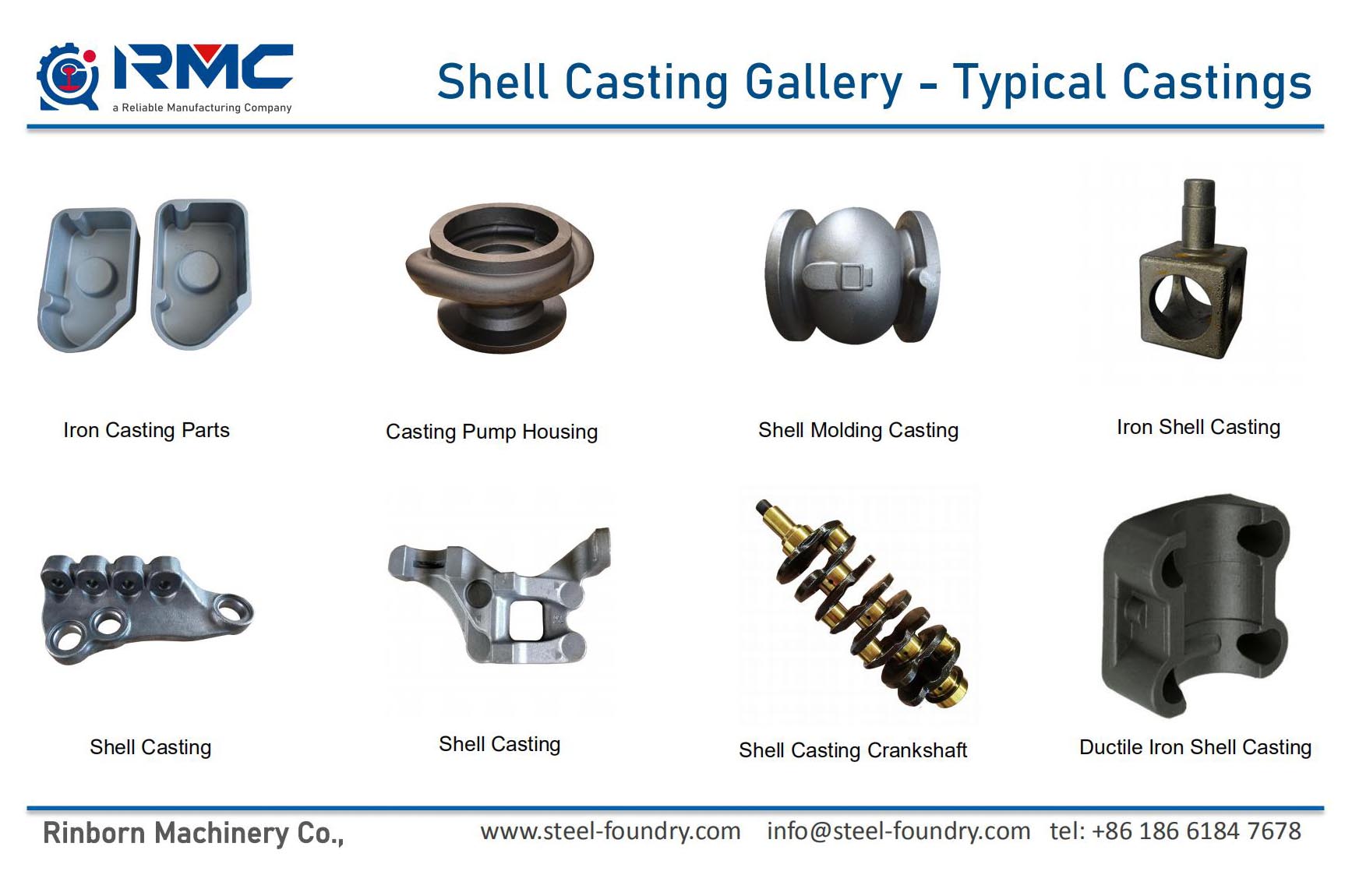

Iimveliso zokuCasa intsimbi yesiko