Ukunyangwa kokushisa kweentsimbi zetsimbi kusekelwe kumzobo wesigaba se-Fe-Fe3C ukulawula i-microstructure ye-castings yensimbi ukufezekisa ukusebenza okufunekayo. Ukunyangwa kokushisa ngenye yeenkqubo ezibalulekileyo kwimveliso yentsimbi yentsimbi. Umgangatho kunye nomphumo wonyango lokushisa uhambelana ngqo nokusebenza kokugqibela kweentsimbi zetsimbi.

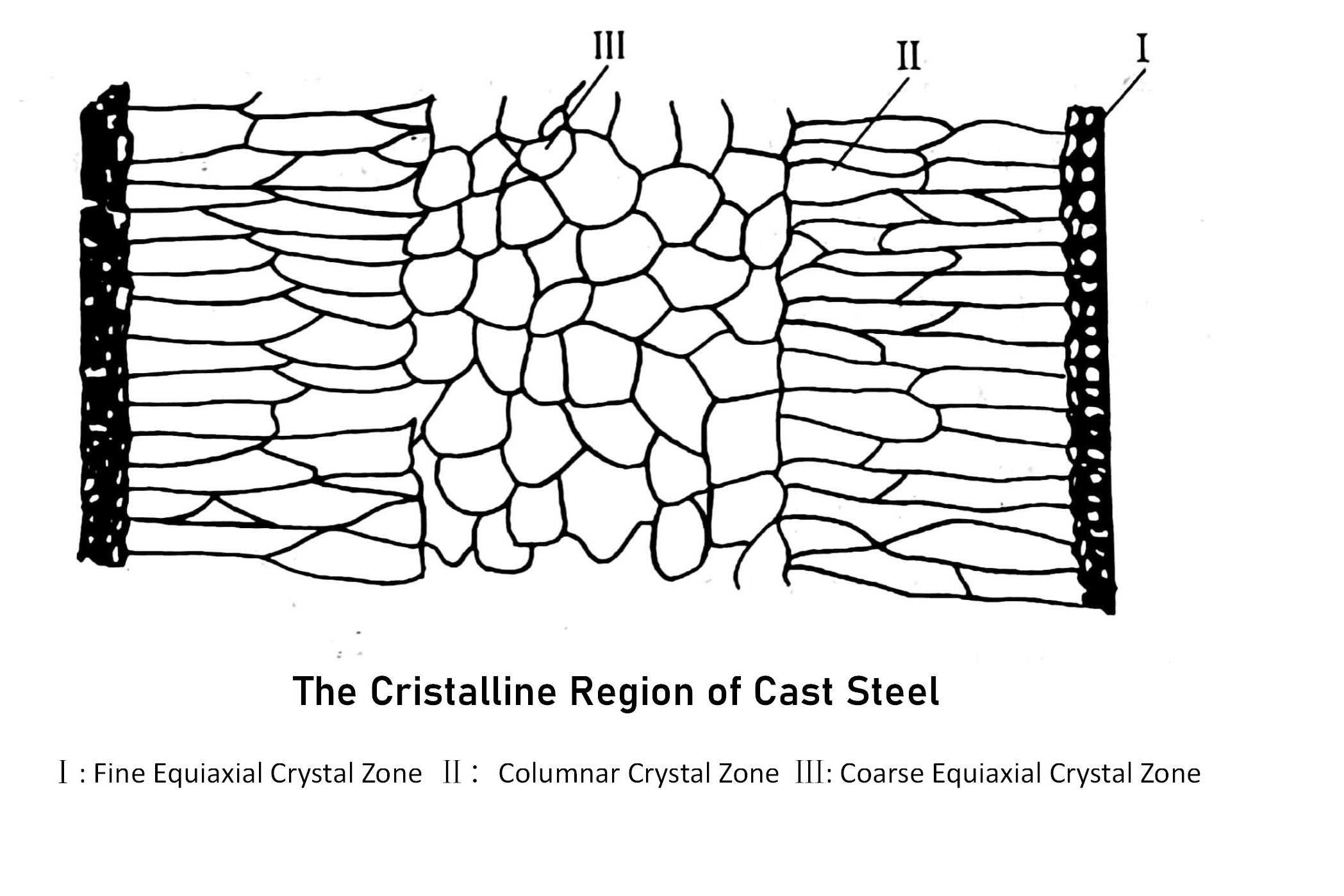

Isakhiwo se-as-cast of castings yetsimbi sixhomekeke ekubunjweni kweekhemikhali kunye nenkqubo yokuqinisa. Ngokubanzi, kukho ulwahlulo olubi kakhulu lwe-dendrite, ulwakhiwo olungalinganiyo kunye neenkozo ezirhabaxa. Ngoko ke, ukuchithwa kwensimbi ngokuqhelekileyo kufuneka kuphathwe ukushisa ukuze kupheliswe okanye kuncitshiswe impembelelo yeengxaki ezingentla, ukwenzela ukuba kuphuculwe iimpawu zomatshini zentsimbi. Ukongeza, ngenxa yomahluko kulwakhiwo kunye nobukhulu bodonga lwentsimbi yokuphosa, iindawo ezahlukeneyo zokubunjwa okufanayo zineendlela ezahlukeneyo zombutho kwaye zivelisa uxinzelelo olukhulu olushiyekileyo lwangaphakathi. Ngoko ke, iintsimbi zensimbi (ingakumbi i-alloy steel castings) kufuneka zihanjiswe ngokubanzi kwimeko yokushisa.

1. Iimpawu zoNyango loBushushu kwiiNsimbi zentsimbi

I-1) Kwisakhiwo se-as-cast of castings yensimbi, kukho rhoqo i-dendrites enqabileyo kunye nokwahlula. Ngethuba lokunyanga ukushisa, ixesha lokufudumeza kufuneka libe phezulu kancinci kuneengxenye zetsimbi zokubunjwa okufanayo. Ngexesha elifanayo, ixesha lokubamba i-austenitization kufuneka landiswe ngokufanelekileyo.

I-2) Ngenxa yokwahlula okunzulu kwesakhiwo se-as-cast ye-alloy steel castings, ukwenzela ukuba kupheliswe impembelelo yayo kwiipropati zokugqibela ze-castings, amanyathelo kufuneka athathwe kwi-homogenize ngexesha lokunyanga ukushisa.

I-3) Ukuphoswa kwensimbi enemilo eyinkimbinkimbi kunye nokwahlukana okukhulu kweendonga, iziphumo ezinqamlekileyo kunye nezinto ezixinzelelekileyo kufuneka ziqwalaselwe ngexesha lonyango lokushisa.

4) Xa unyango lobushushu lwenziwa kwi-castings yensimbi, kufuneka ibe nengqiqo ngokusekelwe kwiimpawu zayo zesakhiwo kwaye uzame ukuphepha ukuguqulwa kwee-castings.

2. IiNdlela eziPhambili zeNkqubo yoNyango loBushushu kwi-Steel Castings

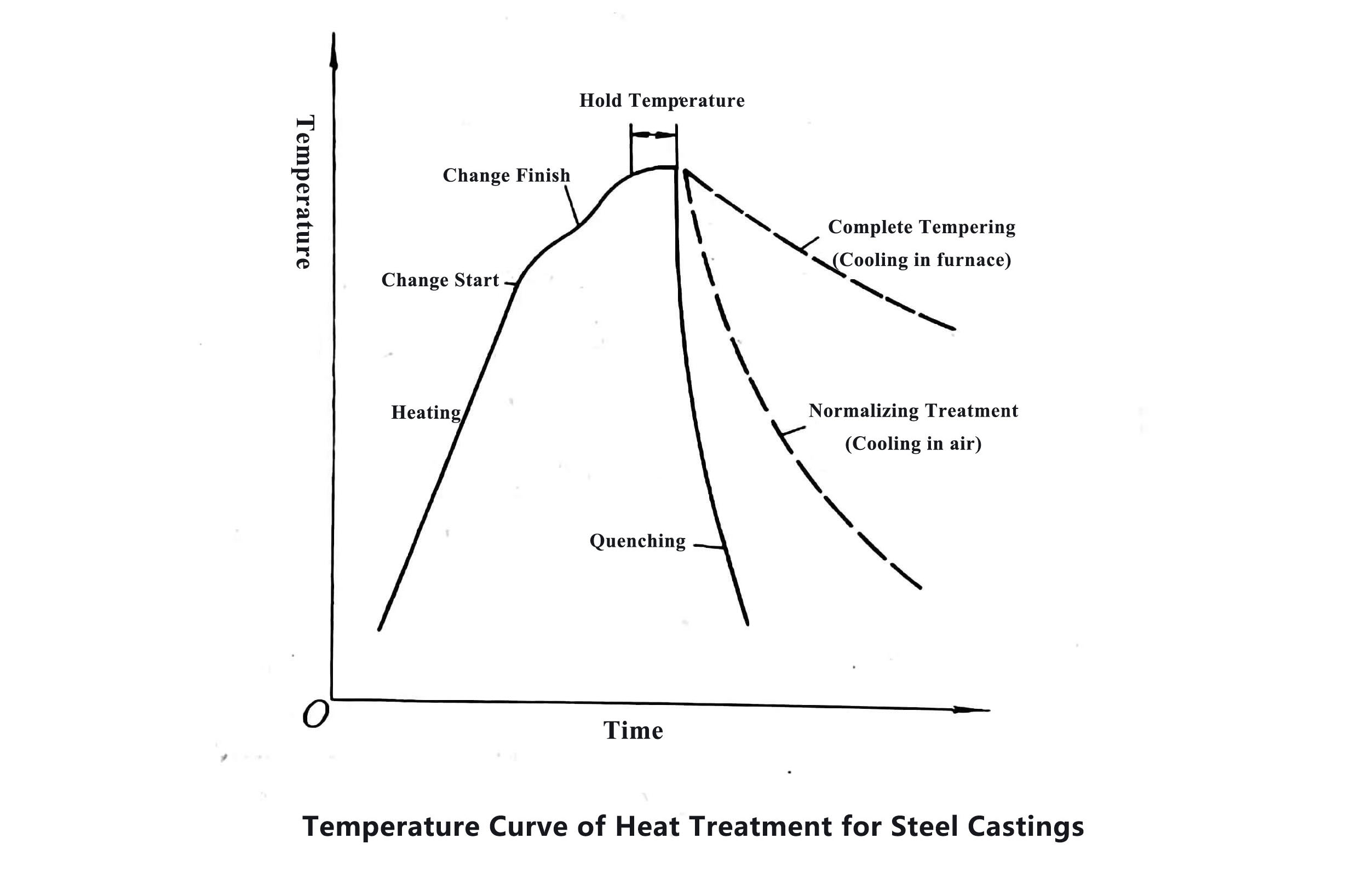

Ukunyangwa kobushushu kweentsimbi zentsimbi kubandakanya izigaba ezithathu: ukufudumeza, ukugcinwa kobushushu kunye nokupholisa. Ukumiselwa kweeparamitha zenkqubo kufuneka kusekelwe kwinjongo yokuqinisekisa umgangatho wemveliso kunye neendleko zokulondoloza.

1) Ukufudumala

Ukufudumeza yeyona nkqubo idla amandla kakhulu kwinkqubo yonyango lobushushu. Iimpawu eziphambili zezobugcisa zenkqubo yokufudumala kukukhetha indlela efanelekileyo yokufudumala, isantya sokufudumala kunye nendlela yokutshaja.

(1) Indlela yokufudumeza. Iindlela zokufudumeza zokuphoswa kwentsimbi ikakhulu zibandakanya ukufudumeza okukhazimlayo, ukufudumala kwebhafu yetyuwa kunye nokufudumala kwe-induction. Umgaqo wokukhetha indlela yokufudumala ikhawuleza kwaye ifanayo, kulula ukuyilawula, ukusebenza kakuhle kunye neendleko eziphantsi. Xa ukufudumala, i-Foundry ngokubanzi iqwalasela ubungakanani besakhiwo, ukubunjwa kweekhemikhali, inkqubo yokunyanga ukushisa kunye neemfuno zomgangatho wokuphosa.

(2) Isantya sokufudumeza. Ukuphoswa kwensimbi ngokubanzi, isantya sokufudumala asinakukhawulelwa, kwaye ubuninzi bamandla esithando somlilo sisetyenziselwa ukufudumeza. Ukusetyenziswa kokutshaja kwesithando somlilo kunokunciphisa kakhulu ixesha lokufudumeza kunye nomjikelezo wokuvelisa. Enyanisweni, phantsi kweemeko zokufudumeza ngokukhawuleza, akukho hysteresis ecacileyo yokushisa phakathi kwendawo yokuphosa kunye nengundoqo. Ukufudumeza okucothayo kuya kubangela ukunciphisa ukusebenza kakuhle kwemveliso, ukwanda kokusetyenziswa kwamandla, kunye ne-oxidation enzulu kunye ne-decarburization kumphezulu wokuphosa. Nangona kunjalo, kwezinye ii-castings ezinemilo enzima kunye nezakhiwo, ubuninzi beendonga ezinkulu, kunye noxinzelelo olukhulu lwe-thermal ngexesha lokufudumala, isantya sokufudumala kufuneka silawulwe. Ngokuqhelekileyo, ubushushu obuphantsi kunye nokufudumeza okucothayo (ngaphantsi kwe-600 °C) okanye ukuhlala kubushushu obuphantsi okanye obuphakathi bunokusetyenziswa, kwaye ukufudumeza okukhawulezileyo kunokusetyenziswa kwiindawo zobushushu obuphezulu.

(3) Indlela yokulayisha. Umgaqo wokuba iintsimbi zetsimbi kufuneka zifakwe kwisithando somlilo kukusebenzisa ngokupheleleyo indawo esebenzayo, uqinisekise ukufudumeza okufanayo kunye nokubeka i-castings ukukhubazeka.

2) I-Insulation

Iqondo lokushisa lokubamba i-austenitization ye-castings yensimbi kufuneka ikhethwe ngokuhambelana neekhemikhali zentsimbi kunye neempawu ezifunekayo. Iqondo lobushushu lokubamba liphezulu kancinane (malunga ne-20 °C) kuneendawo zentsimbi ezibunjwayo zokwakheka okufanayo. Kwi-eutectoid steel castings, kufuneka kuqinisekiswe ukuba i-carbides inokufakwa ngokukhawuleza kwi-austenite, kwaye i-austenite inokugcina iinkozo ezintle.

Izinto ezimbini kufuneka ziqwalaselwe ixesha lokugcinwa kokushisa kweentsimbi zetsimbi: into yokuqala kukwenza ukushisa kwendawo yokuphosa kunye neyunifomu engundoqo, kwaye into yesibini kukuqinisekisa ukufana kwesakhiwo. Ngoko ke, ixesha lokubamba ngokuyinhloko lixhomekeke kwi-thermal conductivity of casting, ubukhulu bodonga lwecandelo kunye nezinto ze-alloy. Ngokuqhelekileyo, ukuchithwa kwensimbi ye-alloy kufuna ixesha elide lokubamba kune-carbon steel castings. Ubunzima bodonga lokuphosa ngokuqhelekileyo lusisiseko esisisiseko sokubala ixesha lokubamba. Ngexesha lokubamba unyango olushushu kunye nonyango lokuguga, izinto ezinje ngenjongo yonyango lobushushu, ubushushu bokubamba kunye nenqanaba lokusasazwa kwezinto kufuneka ziqwalaselwe.

3) Ukupholisa

Iintsimbi zensimbi zinokupholiswa ngesantya esahlukileyo emva kokugcinwa kobushushu, ukuze kugqitywe ukuguqulwa kwe-metallographic, ukufumana isakhiwo esifunekayo se-metallographic kwaye ufezekise izibonakaliso zokusebenza ezichaziweyo. Ngokuqhelekileyo, ukunyusa izinga lokupholisa kunokuncedisa ukufumana isakhiwo esilungileyo kunye nokucoca iinkozo, ngaloo ndlela kuphuculwe iimpawu zomatshini wokuphosa. Nangona kunjalo, ukuba izinga lokupholisa likhawuleza kakhulu, kulula ukubangela uxinzelelo olukhulu kwi-casting. Oku kunokubangela ukuguqulwa okanye ukuqhekeka kwee-castings ezinezakhiwo ezinzima.

Indawo yokupholisa yonyango lobushushu lokuphoswa kwentsimbi ngokubanzi ibandakanya umoya, ioyile, amanzi, amanzi anetyuwa kunye netyuwa etyhidiweyo.

3. Indlela yoNyango loBushushu yeeNsimbi zeNsimbi

Ngokweendlela ezahlukeneyo zokufudumeza, ukubamba ixesha kunye neemeko zokupholisa, iindlela zokunyanga ubushushu bentsimbi yentsimbi ikakhulu zibandakanya i-annealing, normalizing, quenching, tempering, unyango lwesisombululo, ukuqina kwemvula, unyango lokunciphisa uxinzelelo kunye nonyango lokususa i-hydrogen.

1) Ukucoca.

I-Anealing kukufudumeza intsimbi okwakhiwa kwayo kuyatenxa kwimo yokulinganisa ukuya kwiqondo lobushushu elithile elimiselwe yinkqubo, uze uyipholise ngokucothayo emva kogcino lobushushu (ngokuqhelekileyo ukupholisa ngeziko okanye ukungcwatywa kwikalika) ukufumana inkqubo yonyango lobushushu kufutshane ne isimo sokulingana kwesakhiwo. Ngokokwakheka kwentsimbi kunye nenjongo kunye neemfuno zokufunxa, i-annealing inokohlulwa ibe yi-annealing epheleleyo, i-isothermal annealing, i-spheroidizing annealing, i-recrystallization annealing, i-annealing annealing yoxinzelelo njalo njalo.

(1) Gqibezela isiHlomelo. Inkqubo ebanzi yokufakwa kwe-annealing epheleleyo yile: ukufudumeza ukuphosa kwentsimbi ukuya kwi-20 °C-30 °C ngaphezu kwe-Ac3, ukuyibamba ixesha elithile, ukwenzela ukuba ulwakhiwo lwentsimbi luguqulwe ngokupheleleyo lube yi-austenite, kwaye luphole ngokucothayo (ngokuqhelekileyo Ukupholisa ngesithando somlilo) kwi-500 ℃- 600 ℃, kwaye ekugqibeleni yaphola emoyeni. Into ebizwa ngokuba epheleleyo ithetha ukuba isakhiwo esipheleleyo se-austenite sifunyenwe xa sishushu.

Injongo ye-annealing epheleleyo ibandakanya ikakhulu: eyokuqala kukuphucula ubume oburhabaxa kunye nokungalinganiyo okubangelwa kukusebenza okushushu; okwesibini kukunciphisa ukuqina kwekhabhoni yentsimbi kunye ne-alloy steel castings ngaphezu kwekhabhoni ephakathi, ngaloo ndlela kuphuculwe ukusebenza kwabo kokusika (ngokubanzi, Xa ukuqina kwe-workpiece kuphakathi kwe-170 HBW-230 HBW, kulula ukunqumla. iphezulu okanye ingaphantsi kolu luhlu, iya kwenza ukusika kube nzima); okwesithathu kukuphelisa uxinzelelo lwangaphakathi lwentsimbi.

Uluhlu lokusetyenziswa kwe-annealing epheleleyo. I-annealing epheleleyo ifaneleka kakhulu kwi-carbon steel kunye ne-alloy castings yensimbi kunye nokubunjwa kwe-hypoeutectoid kunye nomxholo wekhabhoni ukusuka kwi-0.25% ukuya kwi-0.77%. Intsimbi ye-Hypereutectoid ayifanele ifakwe ngokupheleleyo, kuba xa intsimbi ye-hypereutectoid ifudunyezwa ngaphezulu kwe-Accm kwaye ipholile ngokukhawuleza, i-cementite yesibini iya kudlula kumda wengqolowa ye-austenite kwimilo yenethiwekhi, eyenza amandla, iplastiki kunye nokuqina kwempembelelo yentsimbi. ukuhla.

(2) I-Isothermal Annealing. I-Isothermal annealing ibhekisa ekufudumezweni kwentsimbi ukuya kuma-20 °C - 30 °C ngaphezulu kwe-Ac3 (okanye i-Ac1), emva kokubamba ixesha elithile, ukupholisa ngokukhawuleza kubushushu obuphezulu be-subcooled austenite isothermal curve, emva koko ubambe ixesha elithile. ixesha ( Pearlite transformation zone). Emva kokuba i-austenite iguqulwe ibe yi-pearlite, ipholisa ngokukhawuleza.

(3) I-Spheroidizing Annealing. I-Spheroidizing annealing kukufudumeza iintsimbi zentsimbi ukuya kumaqondo obushushu angaphezulu kancinci kune-Ac1, kwaye emva kwexesha elide logcino lobushushu, i-cementite yesibini entsimbini ngokuzenzekelayo iguquka ibe yi-granular (okanye engqukuva) yesamente, kwaye emva koko ngesantya esicothayo Unyango lobushushu. inkqubo yokupholisa kwiqondo lokushisa.

Injongo ye-spheroidizing annealing ibandakanya: ukunciphisa ubulukhuni; ukwenza ulwakhiwo lwe-metallographic lufane; ukuphucula ukusebenza kokusika kunye nokulungiselela ukucima.

I-Spheroidizing annealing isetyenziswa ikakhulu kwiintsimbi ze-eutectoid kunye neentsimbi ze-hypereutectoid (umxholo wekhabhoni omkhulu kuno-0.77%) njengentsimbi yesixhobo sekhabhoni, intsimbi yasentwasahlobo yealloy, intsimbi eqengqelekayo kunye nentsimbi yesixhobo sealloyi.

(4) Ukuthomalalisa uxinezeleko lokuthomalalisa kunye nokuphinda kufakwe intsimbi. Ukuthoba ubushushu boxinzelelo kukwabizwa ngokuba kukuthoba ubushushu obuphantsi. Yinkqubo apho ukugalelwa kwentsimbi kufudunyezwa ukuya kutsho ngaphantsi kweqondo lobushushu le-Ac1 (400 °C - 500 °C), emva koko igcinwe ixesha elithile, ize ipholiswe kancinci ukuya kwiqondo lobushushu begumbi. Injongo yokunciphisa uxinzelelo kukuphelisa uxinzelelo lwangaphakathi lokuphosa. Isakhiwo se-metallographic sensimbi asiyi kutshintsha ngexesha lenkqubo yokunciphisa uxinzelelo. I-recrystallization annealing isetyenziswa ikakhulu ukuphelisa ubume obugqwethekileyo obubangelwa kukulungiswa okubandayo kunye nokuphelisa ukuqina komsebenzi. Iqondo lobushushu lokufudumeza le-recrystallization annealing yi-150 °C - 250 °C ngaphezu kweqondo lobushushu lokuphinda liyikristale. Ukuphinda kuhlaziywe ikristale kunokwenza kwakhona iinkozo ezinde zekristale zibe ziikristale ezilinganayo ezilinganayo emva kokuguquka okubandayo, ngaloo ndlela kushenxise isiphumo sokuqina komsebenzi.

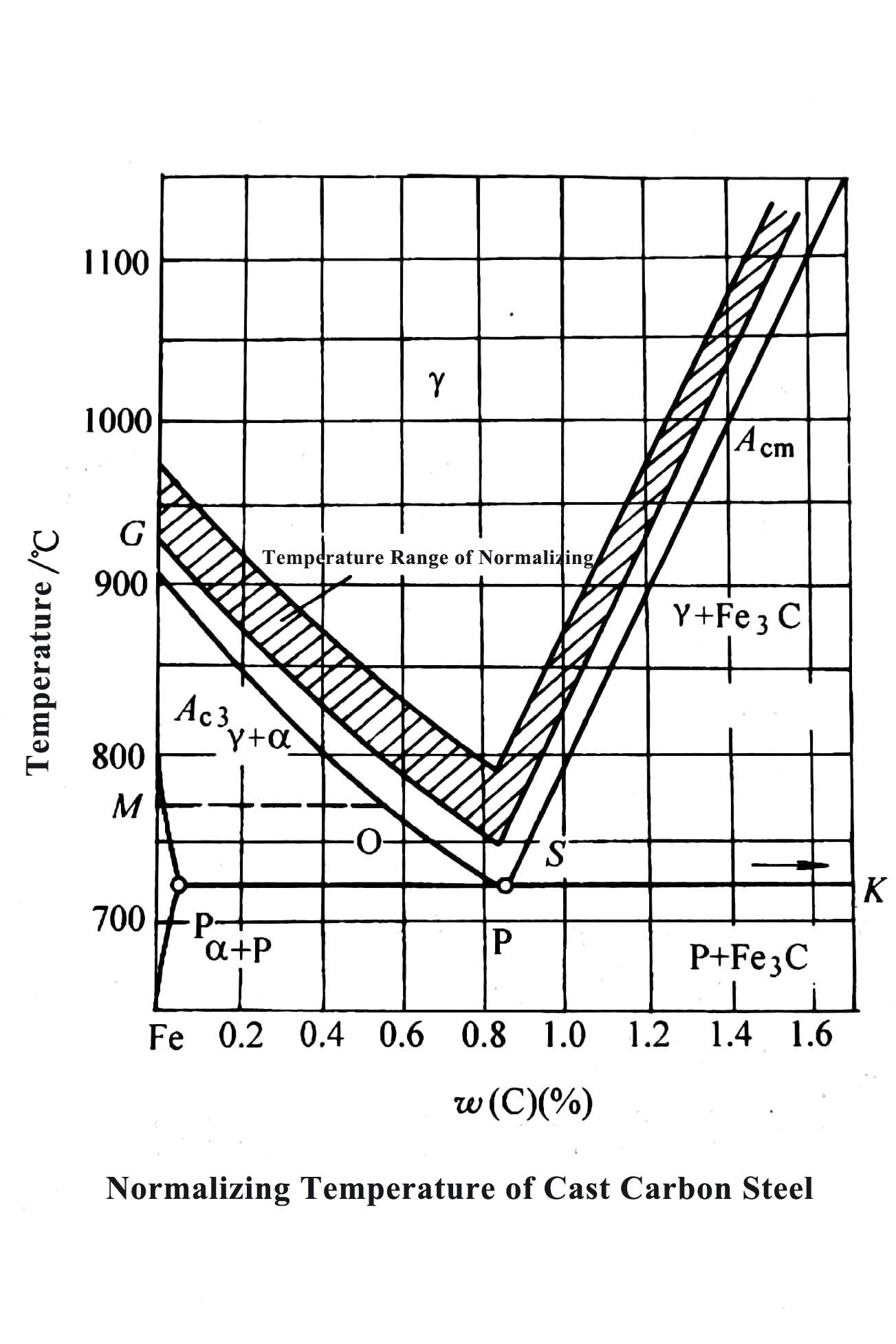

2) Ukulungelelanisa

I-normalizing lunyango lobushushu apho intsimbi ifudunyezwa ukuya kuma-30 ° C - 50 °C ngaphezu kwe-Ac3 (hypoeutectoid steel) kunye ne-Acm (hypereutectoid iron), kwaye emva kwexesha lokugcinwa kobushushu, ipholile kwiqondo lokushisa emoyeni okanye kwi umoya ngenkani. indlela. I-normalizing inezinga lokupholisa elikhawulezayo kune-annealing, ngoko ke ulwakhiwo oluqhelekileyo lucolekile kunolwakhiwo lwe-annealing, kwaye amandla kunye nokuqina kwaso kuphezulu kunoko kwesakhiwo esifakwe emanzini. Ngenxa yomjikelezo omfutshane wemveliso kunye nokusetyenziswa kwezixhobo eziphezulu ze-normalizing, i-normalizing isetyenziswa ngokubanzi kwiintlobo ezahlukeneyo zentsimbi.

Injongo yesiqhelo yahlulwe ngokwezi ndidi zintathu zilandelayo:

(1) Ukuqheleka njengonyango lokugqibela lobushushu

Ukuphoswa kwetsimbi kunye neemfuno zamandla aphantsi, i-normalization ingasetyenziswa njengonyango lokugqibela lobushushu. Ukulungelelanisa kunokuphucula i-grains, i-homogenize isakhiwo, ukunciphisa umxholo we-ferrite kwintsimbi ye-hypoeutectoid, ukwandisa kunye nokuphucula umxholo we-pearlite, ngaloo ndlela kuphuculwe amandla, ukuqina kunye nokuqina kwentsimbi.

(2) Ukulungelelanisa njengonyango lwangaphambili

Ukuphoswa kwentsimbi kunye namacandelo amakhulu, ukulungelelanisa ngaphambi kokucima okanye ukucima kunye nokutshisa (ukucima kunye nokushisa okuphezulu kokushisa) kunokuphelisa isakhiwo se-Widmanstatten kunye nesakhiwo esidibeneyo, kwaye sifumane isakhiwo esihle kunye nesifanayo. Kwi-network cementite ekhoyo kwi-carbon steels kunye ne-alloy tool steels kunye nomxholo wekhabhoni omkhulu kune-0.77%, i-normalization inokunciphisa umxholo we-cementite yesibini kwaye ithintele ukuba iyenze inethiwekhi eqhubekayo, ilungiselela umbutho we-spheroidizing annealing .

(3) Ukuphucula ukusebenza kokusika

Ukulungelelanisa kunokuphucula ukusebenza kokusika kwensimbi ephantsi ye-carbon. Ukuqina kokuphoswa kwentsimbi yekhabhoni ephantsi kuphantsi kakhulu emva kokufakwa kwe-anneal, kwaye kulula ukunamathela kwimela ngexesha lokusika, okukhokelela kuburhabaxa obugqithisileyo. Ngokusebenzisa unyango oluqhelekileyo lobushushu, ubulukhuni be-carbon steel casting castings bunokunyuswa ukuya kwi-140 HBW - 190 HBW, esondele kubunzima obuphezulu bokusika, ngaloo ndlela kuphuculwe ukusebenza kokusika.

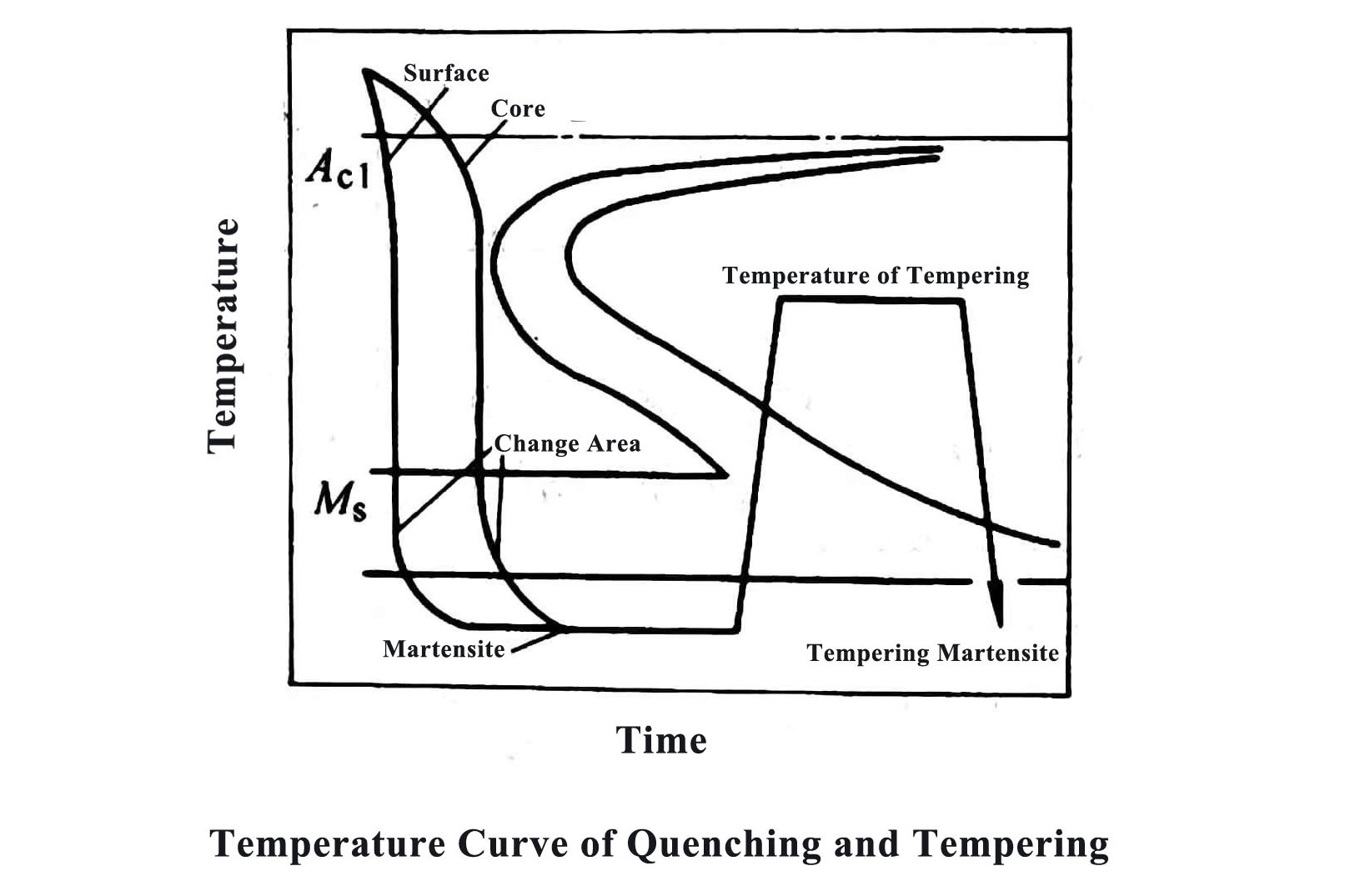

3) Ukucima

Ukucima yinkqubo yokunyanga ukushisa apho i-casting castings ifudumala kwiqondo lokushisa ngaphezu kwe-Ac3 okanye i-Ac1, kwaye emva koko ipholile ngokukhawuleza emva kokubamba ixesha elithile ukuze ifumane isakhiwo esipheleleyo se-martensitic. Iintsimbi zentsimbi kufuneka zihlanjululwe ngexesha emva kokutshisa kakhulu ukuphelisa uxinzelelo lokucima kunye nokufumana iimpawu ezifunekayo zomatshini.

(1) Ukucima ubushushu

Ukucima ubushushu bokufudumala kwentsimbi ye-hypoeutectoid yi-30 ℃-50 ℃ ngaphezu kwe-Ac3; ukucima ubushushu bobushushu bentsimbi ye-eutectoid kunye nentsimbi ye-hypereutectoid yi-30 ℃-50 ℃ ngaphezulu kwe-Ac1. I-Hypoeutectoid carbon steel ifudunyezwa kwiqondo lokushisa elikhankanywe ngasentla ukuze lifumane i-austenite ecocekileyo, kunye nesakhiwo esihle se-martensite sinokufumaneka emva kokucima. Intsimbi ye-eutectoid kunye nentsimbi ye-hypereutectoid iye yafakwa i-spheroidized kwaye yafakwa phambi kokucinywa kunye nokufudumeza, ke emva kokufudumeza ukuya kwi-30℃-50 ℃ ngaphezulu kwe-Ac1 kwaye iqiniselwe ngokungagqibekanga, ulwakhiwo luyi-austenite kunye nenxalenye enganyibilikiyo enganyibilikiyo yokungena kwamasuntswana omzimba weCarbon. Emva kokucima, i-austenite iguqulwa ibe yi-martensite, kwaye iinqununu ze-cementite ezinganyibilikiyo zigcinwa. Ngenxa yobunzima obuphezulu be-cementite, akugcini nje ukunciphisa ubunzima bensimbi, kodwa kuphucula ukuchasana kwayo. Isakhiwo esiqhelekileyo esicinyiweyo sensimbi ye-hypereutectoid ilungile i-martensite ene-flaky, kunye ne-cementite emihle ye-granular kunye nenani elincinci le-austenite egciniweyo isasazwa ngokulinganayo kwi-matrix. Esi sakhiwo sinamandla aphezulu kunye nokuxhatshazwa kokugqoka, kodwa kwakhona kunomlinganiselo othile wokuqina.

(2) Indawo yokupholisa yokucima inkqubo yonyango lobushushu

Injongo yokucima kukufumana i-martensite epheleleyo. Ngako oko, izinga lokupholisa intsimbi ephosiweyo ngexesha lokucima kufuneka libe likhulu kunezinga lokupholisa elibalulekileyo lentsimbi, ngaphandle koko isakhiwo se-martensite kunye neempawu ezihambelanayo azikwazi ukufunyanwa. Nangona kunjalo, izinga lokupholisa eliphezulu kakhulu lingakhokelela ngokulula kwi-deformation okanye ukuqhekeka kokuphosa. Ukuze kuhlangatyezwane nezi mfuno zingentla ngaxeshanye, indawo yokupholisa efanelekileyo kufuneka ikhethwe ngokwezinto zokupholisa, okanye indlela yokupholisa ngeqonga kufuneka yamkelwe. Kuluhlu lweqondo lokushisa lwe-650 ℃-400 ℃, izinga lokuguqulwa kwe-isothermal ye-supercooled austenite yentsimbi yeyona inkulu. Ngoko ke, xa ukuphosa kucinywa, ukupholisa ngokukhawuleza kufuneka kuqinisekiswe kule nqanaba lokushisa. Ngaphantsi kwenqaku likaMs, izinga lokupholisa kufuneka licothise ukuthintela ukuguqulwa okanye ukuqhekeka. Indlela yokucima ngokuqhelekileyo ithatha amanzi, isisombululo esinamanzi okanye ioli. Kwinqanaba lokucima okanye ukucima, imidiya esetyenziswa ngokuqhelekileyo iquka ioli eshushu, isinyithi esinyibilikisiweyo, ityuwa etyhidiweyo okanye i-alkali etyhidiweyo.

Umthamo wokupholisa wamanzi kwindawo yobushushu obuphezulu obuyi-650℃-550℃ yomelele, kwaye umthamo wokupholisa wamanzi kwindawo yobushushu obuphantsi obuyi-300℃-200℃ yomelele kakhulu. Amanzi afaneleke ngakumbi ukucima kunye nokupholisa i-carbon steel castings enemilo elula kunye namacandelo amakhulu. Xa isetyenziselwa ukucima kunye nokupholisa, iqondo lobushushu lamanzi alibikho ngaphezulu kwe-30°C. Ngoko ke, ngokuqhelekileyo yamkelwa ukuqinisa ukujikeleza kwamanzi ukugcina ubushushu bamanzi ngaphakathi koluhlu olufanelekileyo. Ukongezelela, ukufudumeza ityuwa (NaCl) okanye i-alkali (NaOH) emanzini kuya kwandisa kakhulu amandla okupholisa isisombululo.

Eyona nzuzo iphambili yeoli njengendawo yokupholisa kukuba izinga lokupholisa kwindawo yobushushu obuphantsi kwe-300℃-200℃ lisezantsi kakhulu kunamanzi, anokunciphisa kakhulu uxinzelelo lwangaphakathi lwesixhobo sokusebenza esicinyiweyo kunye nokunciphisa ukwenzeka kokuguquka. kunye nokuqhekeka kokuphosa. Kwangaxeshanye, amandla okupholisa i-oyile kuluhlu oluphezulu lobushushu obungama-650℃-550℃ lusezantsi noko, nto leyo engowona monakalo uphambili we-oyile njengendawo yokucima. Ubushushu be-oyile yokucima ngokuqhelekileyo bulawulwa kwi-60 ℃-80 ℃. I-oyile isetyenziselwa ukucima i-alloy castings yensimbi enemilo enzima kunye nokucima i-carbon steel castings kunye namacandelo amancinci kunye neemilo ezinzima.

Ukongeza, ityuwa enyibilikisiweyo ikwasetyenziswa ngokuqhelekileyo njengendawo yokucima, ethi ibe yindawo yokuhlamba ityuwa ngeli xesha. Ibhafu yetyuwa ibonakaliswe yindawo ephezulu yokubilisa kwaye umthamo wayo wokupholisa uphakathi kwamanzi kunye neoli. Ibhafu yetyuwa isoloko isetyenziselwa ukucima kunye nokucima isiteji, kunye nonyango lwe-castings enemilo enzima, imilinganiselo emincinci kunye neemfuno ezingqongqo zokuguqulwa.

4) Ukufudumala

I-Tempering ibhekisela kwinkqubo yokunyanga ukushisa apho i-castings yensimbi ecinyiweyo okanye eqhelekileyo ifudunyezwa kwiqondo lokushisa elikhethiweyo elingaphantsi kwe-Ac1 iphuzu elibalulekileyo, kwaye emva kokubamba ixesha elithile, lipholile ngesantya esifanelekileyo. Ukufudumala ukunyangwa kobushushu kunokuguqula isakhiwo esingazinzanga esifunyenwe emva kokucima okanye ukulungelelanisa kwisakhiwo esizinzileyo sokuphelisa uxinzelelo kunye nokuphucula iplastiki kunye nokuqina kweentsimbi zentsimbi. Ngokubanzi, inkqubo yonyango lobushushu lokucima kunye nonyango olushushu oluphezulu lubizwa ngokuba kukucinywa kunye nonyango olushushu. Iintsimbi ezicinyiweyo zentsimbi kufuneka zihlanjululwe ngexesha, kwaye i-castings yensimbi eqhelekileyo kufuneka ihlanjululwe xa kuyimfuneko. Ukusebenza kweentsimbi zentsimbi emva kokufudumala kuxhomekeke kwiqondo lokushisa, ixesha kunye nenani lamaxesha. Ukwanda kweqondo lokushisa kunye nokwandiswa kwexesha lokubamba nangaliphi na ixesha akukwazi ukukhulula kuphela uxinzelelo lokucima i-castings yensimbi, kodwa kunye nokuguqula i-martensite engazinzanga ecinyiweyo kwi-martensite epholileyo, i-troostite okanye i-sorbite. Amandla kunye nokuqina kweentsimbi zensimbi ziyancipha, kwaye iplastiki iphuculwe kakhulu. Kwezinye iintsimbi zealloyi eziphakathi kunye nezinto ezixubeneyo ezenza ngamandla i-carbides (efana nechromium, i-molybdenum, i-vanadium kunye ne-tungsten, njl.njl.), ukuqina kuyanyuka kunye nokuqina kuncipha xa ubushushu kwi-400℃-500℃. Lo mcimbi ubizwa ngokuba yi-second hard, oko kukuthi, ubunzima bentsimbi ephosiweyo kwimeko epholileyo kufikelela kumlinganiselo ophezulu. Kwimveliso yangempela, i-alloy cast iron cast kunye neempawu zesibini zokuqina kufuneka zihlanjululwe ngamaxesha amaninzi.

(1) Ubushushu obuphantsi

Uluhlu lobushushu bobushushu obuphantsi bobushushu yi-150℃-250℃. Ubushushu obuphantsi bobushushu bunokufumana ubume be-martensite obupholileyo, obusetyenziswa ikakhulu ukucima intsimbi yekhabhoni ephezulu kunye nokucima intsimbi ephezulu yealloy. I-Tempered martensite ibhekisa kulwakhiwo lwe-cryptocrystalline martensite kunye ne-granular carbides entle. Ulwakhiwo lwentsimbi ye-hypoeutectoid emva kokushisa okuphantsi kobushushu bubushushu be-martensite; Ulwakhiwo lwentsimbi ye-hypereutectoid emva kobushushu obuphantsi bobushushu bubushushu be-martensite + carbides + igcinwe i-austenite. Injongo yokushisa okuphantsi kweqondo lokushisa kukuphucula ngokufanelekileyo ukuqina kwentsimbi ecinyiweyo ngelixa ugcina ubunzima obuphezulu (58HRC-64HRC), amandla aphezulu kunye nokumelana nokunxiba, ngelixa kunciphisa kakhulu ukucima uxinzelelo kunye nokunyanzeliswa kweentsimbi zentsimbi.

(2) Ubushushu obuphakathi

Ubushushu bobushushu obuphakathi buphakathi kwe350℃-500℃. Isakhiwo emva kokufudumala kwiqondo lokushisa eliphakathi sisixa esikhulu se-cementite ecolekileyo esasasazwa kwaye isasazwe kwi-matrix ye-ferrite, oko kukuthi, isakhiwo se-troostite esivuthayo. I-ferrite kwisakhiwo se-troostite epholileyo isagcina imilo ye-martensite. Uxinzelelo lwangaphakathi lokuphoswa kwentsimbi emva kobushushu buyapheliswa, kwaye banomda ophezulu we-elastic kunye nomda wesivuno, amandla aphezulu kunye nobunzima, kunye neplastiki elungileyo kunye nokuqina.

(3) Ubushushu obuphezulu

Ubushushu obuphezulu bobushushu bobushushu buqhelekile bungama-500°C-650°C, kwaye inkqubo yonyango lobushushu edibanisa ukucinywa kunye nobushushu obulandelayo bobushushu obuphezulu budla ngokubizwa ngokuba kukucinywa nokuthomalalisa unyango. Isakhiwo emva kokushisa okuphezulu kweqondo lokushisa yi-sorbite epholileyo, oko kukuthi, i-cementite ecocekileyo kunye ne-ferrite. I-ferrite kwi-sorbite epholileyo yi-polygonal ferrite ehamba ngokuphindaphindiweyo. Ukuphoswa kwentsimbi emva kobushushu obuphezulu kuneempawu ezilungileyo ezibanzi zoomatshini ngokwamandla, iplastiki kunye nokuqina. Ubushushu obuphezulu bobushushu busetyenziswa ngokubanzi kwintsimbi yekhabhoni ephakathi, intsimbi ephantsi yealloy, kunye neendawo ezahlukeneyo ezibalulekileyo zolwakhiwo ezinamandla anzima.

5) Solid SolutionTreatment

Injongo ephambili yonyango lwesisombululo kukunyibilikisa i-carbides okanye ezinye izigaba ezinqambileyo kwisisombululo esiqinileyo sokufumana i-supersaturated single-phase structure. Ukugalelwa kwentsimbi engatyiwa yi austenitic, intsimbi ye austenitic manganese kunye nemvula eyenza lukhuni intsimbi engatyiwayo kufuneka ngokubanzi ibe sisisombululo esomeleleyo. Ukukhethwa kweqondo lokushisa kwesisombululo kuxhomekeke kukwakheka kweekhemikhali kunye nomzobo wesigaba sensimbi ephosiweyo. Iqondo lobushushu le-austenitic manganese steel castings ngokuqhelekileyo yi-1000 ℃ - 1100 ℃; iqondo lobushushu le austenitic chromium-nickel castings steel stainless jikelele 1000℃-1250℃.

Ukuphakama komxholo wekhabhoni kwintsimbi etyhidiweyo kunye nezinto ezinganyibilikiyo ngakumbi, kokukhona ubushushu besisombululo esiqinileyo kufuneka bube phezulu. Ukwenzela imvula eqinisa iintsimbi eziqulethwe ngobhedu, ukuqina kweentsimbi zokusahlela kuyanda ngenxa yemvula yezigaba ezinobhedu oluqinileyo kwimeko yokuphola ngexesha lokupholisa. Ukuze uthambise isakhiwo kunye nokuphucula ukusebenza kokucubungula, i-castings yensimbi kufuneka ibe yisisombululo esiqinileyo siphathwe. Ubushushu besisombululo sayo yi-900℃-950℃.

6) Imvula eyenza Unyango olunzima

Unyango lokuqina kwemvula lunyango lokuqinisa ukusasazwa olwenziwa phakathi koluhlu lobushushu, okwaziwa ngokuba kukuguga okwenziweyo. Undoqo wonyango lokuqina kwemvula kukuba kumaqondo obushushu aphezulu, i-carbides, i-nitrides, iikhompawundi ze-intermetallic kunye nezinye izigaba ezingazinzanga eziphakathi zihlanjululwa ukusuka kwisisombululo esiqinileyo se-supersaturated kwaye zisasazwe kwi-matrix, ngaloo ndlela zenza ukuba intsimbi yentsimbi ibe ngokubanzi Ukuphuculwa kweepropathi zoomatshini kunye nobunzima.

Ubushushu bonyango lokuguga buchaphazela ngokuthe ngqo ukusebenza kokugqibela kweentsimbi zetsimbi. Ukuba iqondo lokushisa lokuguga liphantsi kakhulu, isigaba sokuqina kwemvula siya kudlula ngokukhawuleza; ukuba ukushisa kokuguga kuphezulu kakhulu, ukuqokelela kwesigaba esincitshisiweyo kuya kubangela ukugqithisa, kwaye ukusebenza kakuhle akuyi kufumaneka. Ke ngoko, isiseko kufuneka sikhethe ubushushu obufanelekileyo bokuguga ngokwenqanaba lentsimbi ephosiweyo kunye nokusebenza okuchaziweyo kwentsimbi. Iqondo lobushushu ekwaluphaleni intsimbi austenitic ubushushu-resistant ubushushu ngokubanzi 550℃-850℃; iqondo lobushushu ekwaluphaleni eliphezulu-amandla imvula ukuqina cast intsimbi ngokuqhelekileyo 500℃.

7) Unyango loNcedo lweStress

Injongo yonyango lobushushu boxinzelelo kukuphelisa uxinzelelo, ukucima uxinzelelo kunye noxinzelelo olwenziwe ngomatshini, ukuze kuzinziswe ubungakanani bokuphosa. Unyango lobushushu bokunciphisa uxinzelelo lufudunyezwa ngokubanzi ukuya kwi-100 ° C-200 ° C ngaphantsi kwe-Ac1, emva koko lugcinwe ixesha elithile, kwaye ekugqibeleni lupholiswe ngesithando somlilo. Isakhiwo sentsimbi yentsimbi asizange sitshintshe ngexesha lenkqubo yokunciphisa uxinzelelo. Iintsimbi zekhabhoni eziphoswayo, intsimbi ephantsi-ingxubevange yentsimbi kunye nentsimbi ephezulu yealloy castings zonke zinokuba phantsi konyango loxinzelelo.

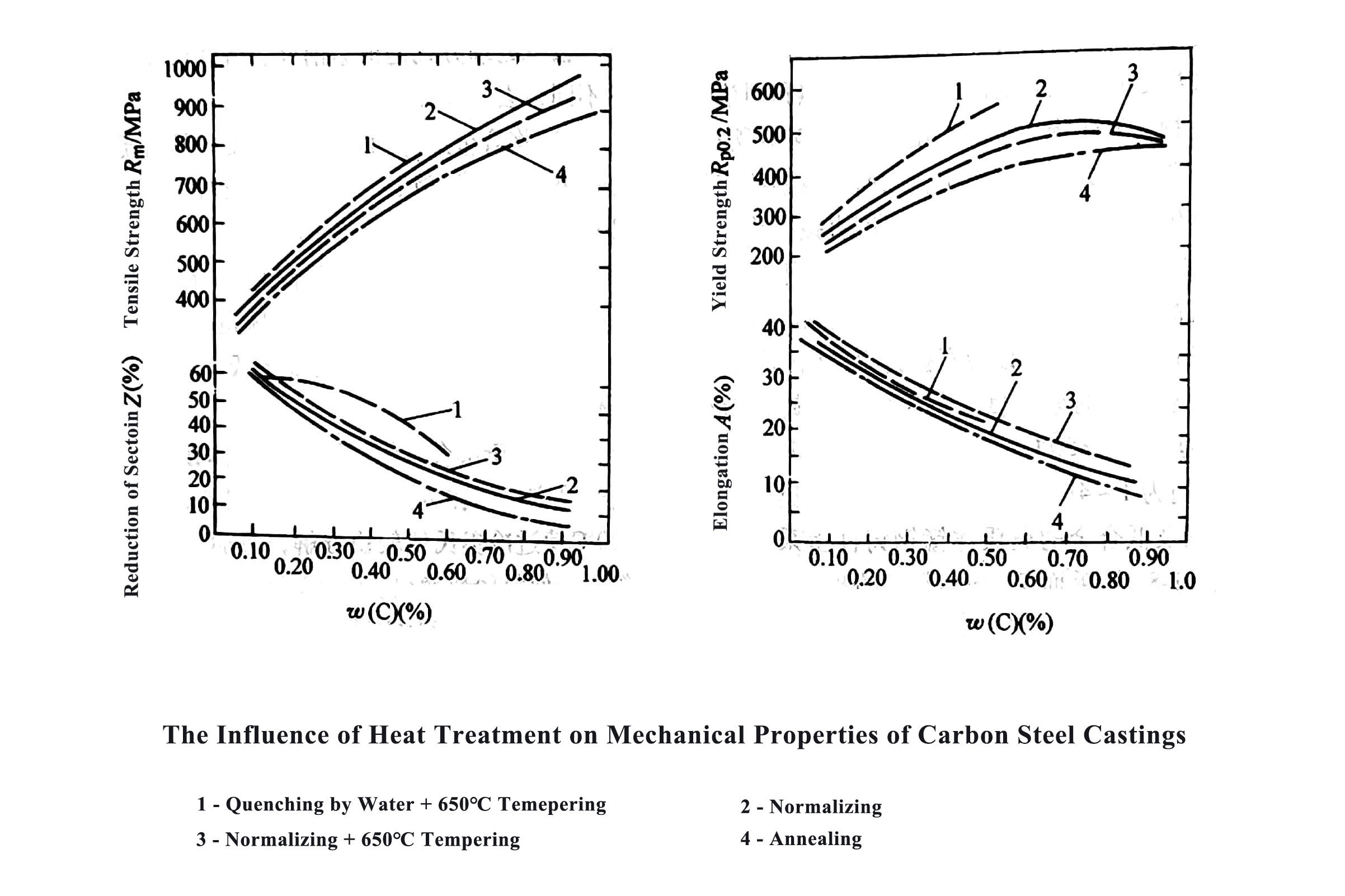

4. Isiphumo soNyango loBubushushu kwiiPropati zeNtsimbi yokuCasa

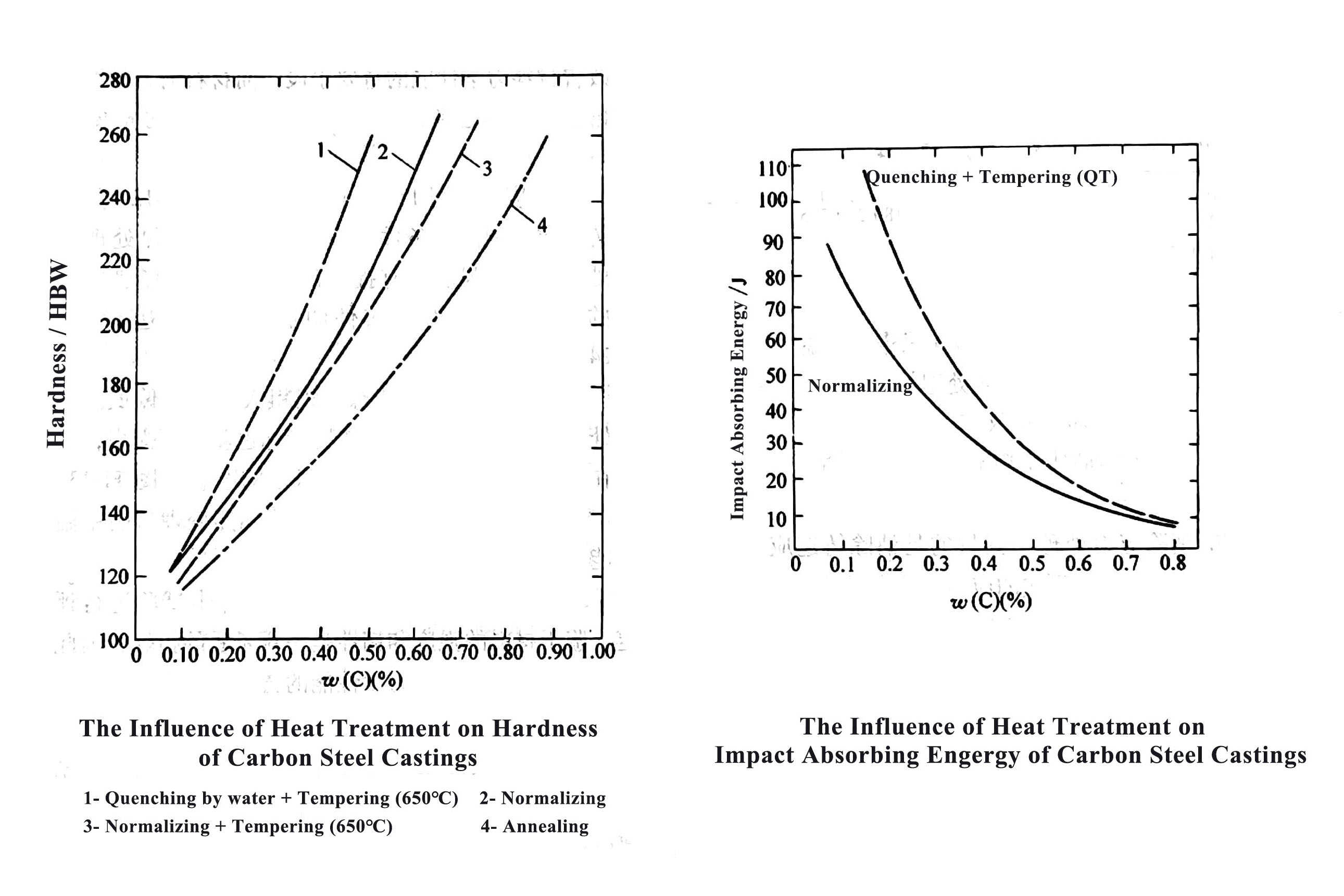

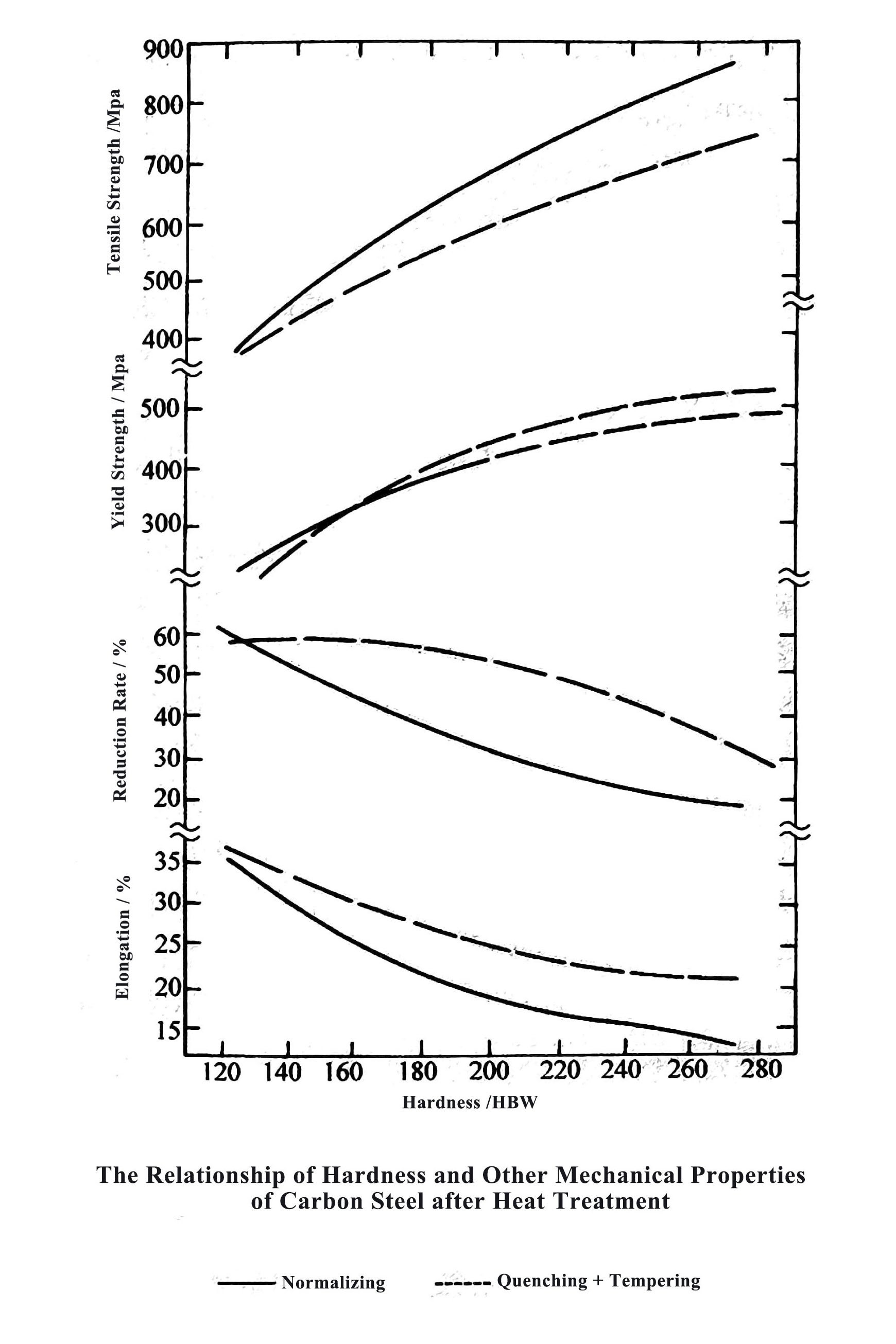

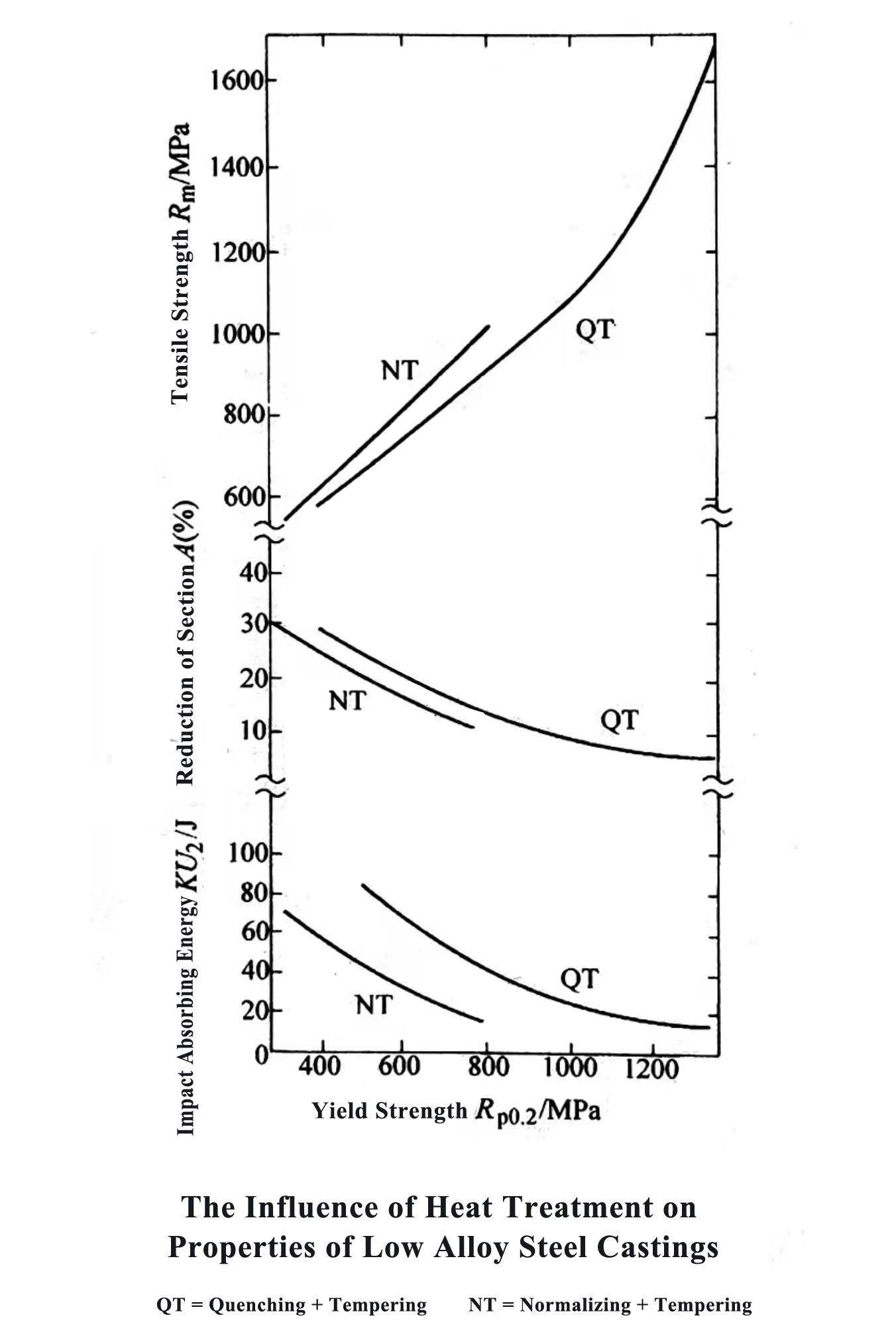

Ukongeza ekusebenzeni kweentsimbi zetsimbi ngokuxhomekeke kukwakheka kweekhemikhali kunye nenkqubo yokuphosa, iindlela ezahlukeneyo zonyango lobushushu zingasetyenziselwa ukwenza ukuba zibe neempawu ezibalaseleyo zomatshini. Injongo eqhelekileyo yenkqubo yokunyanga ukushisa kukuphucula umgangatho wokuphosa, ukunciphisa ubunzima bokuphosa, ukwandisa ubomi benkonzo kunye nokunciphisa iindleko. Ukunyanga ukushisa kuyindlela ebalulekileyo yokuphucula iimpawu zomatshini zokuphosa; iipropathi mechanical of castings isalathisi esibalulekileyo ekugwebeni umphumo wonyango lokushisa. Ukongeza kwezi zakhiwo zilandelayo, i-Foundry kufuneka iphinde iqwalasele izinto ezifana neenkqubo zokucubungula, ukusika ukusebenza kunye neemfuno zokusetyenziswa kwee-castings xa kushushu-ukuphatha ukushisa kwensimbi.

1) Impembelelo yoNyango loBushushu kuMandla okuCasa

Ngaphantsi kwemeko yokubunjwa kwensimbi efanayo, amandla okuchithwa kwetsimbi emva kweenkqubo ezahlukeneyo zonyango lokushisa kunomkhuba wokwandisa. Ngokuqhelekileyo, amandla okuqina e-carbon steel castings kunye ne-low alloy castings enokufikelela kwi-414 Mpa-1724 MPa emva konyango lobushushu.

2) Umphumo woNyango loBushushu kwiPlastiki ye-Steel Castings

Isakhiwo se-as-cast of castings yensimbi i-coarse kwaye iplastiki iphantsi. Emva kokunyanga ukushisa, i-microstructure yayo kunye neplastiki iya kuphuculwa ngokufanelekileyo. Ngokukodwa i-plasticity ye-castings yensimbi emva kokucima kunye nokunyangwa kwe-tempering (ukucima + ukushisa okuphezulu kokushisa) kuya kuphuculwa kakhulu.

3) Ukuqina kweentsimbi zentsimbi

Isalathiso sokuqina kweentsimbi zentsimbi sihlala sivavanywa ngovavanyo lwempembelelo. Ekubeni amandla kunye nokuqina kweentsimbi zetsimbi zimbini zezibonakaliso eziphikisanayo, i-Foundry kufuneka ithathele ingqalelo ebanzi ukukhetha inkqubo efanelekileyo yokushisa ukushisa ukwenzela ukuba kufezekiswe iipropati ezibanzi zomatshini ezifunwa ngabathengi.

4) Impembelelo yoNyango loBushushu kuBulukhuni beCastings

Xa ukuqina kwentsimbi etyhidiweyo kuyafana, ubunzima bentsimbi emva kokunyangwa kobushushu bunokubonisa ngokungqongqo amandla entsimbi. Ngoko ke, ubunzima bunokusetyenziswa njengesalathisi enembileyo ukuqikelela ukusebenza kwentsimbi ephosiweyo emva kokunyanga ubushushu. Ngokuqhelekileyo, ukuqina kwe-carbon steel castings kunokufikelela kwi-120 HBW - 280 HBW emva konyango lobushushu.

Ixesha lokuposa: Jul-12-2021