Uyilo lweRiser ngumba obalulekileyo wenkqubo yokuphosa, eqinisekisa ukuba ukujula akunaziphene ezifana nokushwabana kwemingxuma kunye neporosity. IiRisers, ezikwaziwa njengezokutya, zisebenza njengemithombo yesinyithi esinyibilikisiweyo esondla ukugaywa njengoko siqina kwaye sisebenza.

Uyilo lokuKhuphuka lokuCasa intsimbi

In intsimbi yokutyala imali, injongo ephambili yoyilo lokunyuka kukuqinisekisa ukondla okwaneleyo kwentsimbi etyhidiweyo ukuhlawulela ukuncipha kwe-volumetric ngexesha lokuqina. Intsimbi ithande ukuba namazinga aphezulu okucutheka, nto leyo eyenza uyilo olusebenzayo lokunyuka lube baluleke kakhulu.

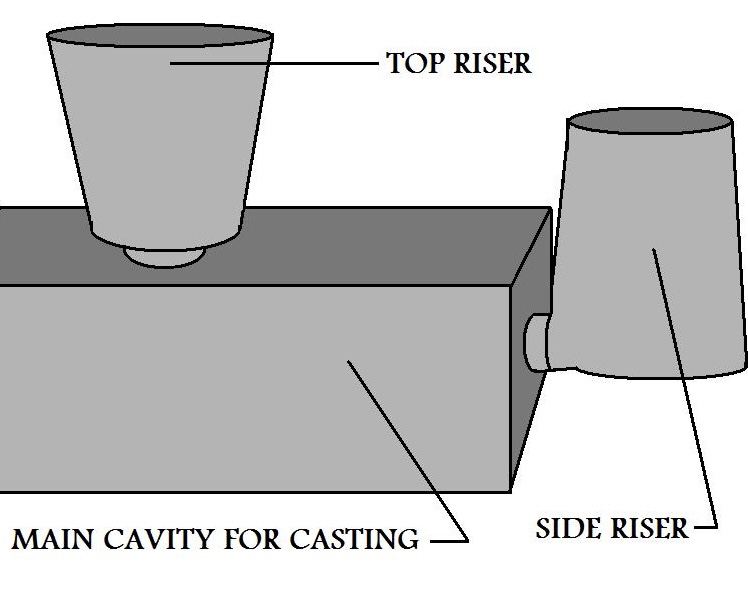

Ukuphoswa kwentsimbi, iindidi ezimbini eziphambili zokunyuka zisetyenziswa:izinyusi ezivulekileyo kwayeabavukeli abaziimfama. Izinyusi ezivulekileyo zisesibhakabhakeni, ngelixa izinyusi ezingaboniyo zivalelwe ngaphakathi komngundo. Izinyusi ezingaboniyo zisebenza kakuhle ekunciphiseni ilahleko yobushushu.

Izikhuphukeli kufuneka zibekwe kwelona candelo linzima lokusakha apho kunokwenzeka khona ukushwabana. Ubungakanani kunye nemilo yokunyuka kufuneka yenziwe ukuze kuqinisekiswe umthamo owaneleyo wentsimbi etyhidiweyo. Iziphakamisi zeCylindrical ziqhele ukusetyenziselwa ukukhululeka kwazo kunye nokusebenza kakuhle ekutyeni. Imikhono ye-insulating kunye nezixhobo ze-exothermic zihlala zisetyenziselwa ukugcina iqondo lokushisa lokunyuka, ukuqinisekisa ukuba lihlala linyibilikile ixesha elide kunokuphosa.

Uyilo lokunyuka lokuCalwa kwentsimbi

Kubautyalo-mali lwentsimbi, ngokukodwa i-gray kunye ne-ductile iron, injongo kukulawula iimpawu zokwandisa ngexesha lokuqina. Ngokungafaniyo nentsimbi, ezinye iintlobo zentsimbi zanda ngexesha lokugqibela lokuqiniswa, ukunciphisa imfuno yokunyuka okukhulu.

Ukunyuka okumfama zikhethwa kwi-iron castings ngenxa yokusebenza kwazo kakuhle. Kwi-iron ductile, izikhuphukeli ezincinci zihlala zanele ngenxa yokwandiswa kwegraphite ngexesha lokuqina.

Izinyusi ezincinci, ezixineneyo zingasetyenziselwa ukuphosa intsimbi. Ubume bunokwahluka kodwa kufuneka bucuthe indawo engaphezulu evezwe kulahleko lobushushu ngelixa unyusa ukusebenza kakuhle kokutyisa. Iingqele (izinto ezifunxa ubushushu) ngamanye amaxesha zisetyenziswa kunye nezinyusi ukulawula izinga lokupholisa kunye nokukhuthaza ukuqina okuya ngakulo ngakwisinyusi.

.jpg)

Uyilo lokunyuka lwe-Non-FerrousI-alloy Castings

Iialloyi ezingenayo i-ferrous, ezifana ne-aluminiyam kunye ne-alloys yobhedu, zineendlela ezahlukeneyo zokuziphatha zokuqiniswa xa kuthelekiswa nesinyithi. Eyona njongo iphambili kukuthintela iziphene ezifana ne-shrinkage porosity kunye nokuqinisekisa ukuzaliswa okupheleleyo kokungunda.

Ukuphoswa kwe-non-ferrous, zombini izinyuko ezivulekileyo neziyimfama zisetyenziswa, kuxhomekeke kwi-alloy kunye noyilo lokuphosa. Izinyusi ezivulekileyo zixhaphake kakhulu kwiicastings ezincinci, ngelixa izinyusi ezingaboniyo zisetyenziselwa ukuphosa okukhulu.

Iialloyi ezingenayo i-ferrous zifuna ukuba izinyusi zibekwe kweyona ndawo iphakamileyo yokuphosa ukuze kusetyenziswe umxhuzulane.

Ubungakanani bokuphakama kufuneka buchaze ubuninzi obuphantsi kunye namazinga aphezulu okucutheka kweealloyi ezingenayo i-ferrous. Izinyusi ezifakwe ngetapered okanye ezinentamo zinokunceda ekunciphiseni ilahleko yobushushu kunye nokuphucula ukusebenza kakuhle kokutyisa. I-Insulation ibalulekile kwii-alloys ezingenayo i-ferrous, njengoko ziqina ngokubanzi kumaqondo obushushu asezantsi. Iimathiriyeli ze-exothermic kunye nemikhono ye-insulating inokunceda ukugcina imeko enyibilikayo yesikhuphukeli ixesha elide.

Ixesha lokuposa: Dec-20-2024