IiNdlela zokuQinisekisa

Ngethuba lenkqubo yokuphosa, ukuqiniswa kwee-castings kwenzeka xa isinyithi esityhidiweyo siguquka ukusuka kulwelo ukuya kwimeko eqinileyo. Le nkqubo inokwahlulwa ngokubanzi ngokweendlela ezintathu:nucleation, ukukhula kwedendritic, kwayeukubunjwa kwesakhiwo sengqolowa. Ngexesha le-nucleation, iincinci ezincinci eziqinileyo zenza ngaphakathi kwentsimbi engamanzi. Ezi nuclei zikhula zibe zizakhiwo ze-dendritic, ziphuma kwipatheni efana nomthi. Ubume bokugqibela beenkozo zeiicastingskumiselwa ngokukhula kwezi dendrites kunye nokusebenzisana kwazo nendawo yokupholisa.

Ukuhlanganiswa kwee-alloys ezahlukeneyo

Ii-alloys ezahlukeneyo ziqina ngeendlela ezizodwa, eziphenjelelwa kukwakheka kweekhemikhali kunye neempawu ezishushu:

Iingxube zeAluminiyam: I-alloys ye-aluminiyam ngokuqhelekileyo ibonisa iqondo eliphezulu lokumanzi, livumela ukubunjwa okuntsokothileyo kunye nokuncinci. Ukuqiniswa kwabo kudla ngokubandakanya ukubunjwa kwesakhiwo esilungileyo, esilinganayo. Nangona kunjalo, ii-alloys ze-aluminium zithambekele ekunciphiseni i-porosity kunye nokukrazula okushushu, okunokuchaphazela umgangatho wokuphosa.

Intsimbi kunyeIingxube zentsimbi: Intsimbi yentsimbi iqina kunye nesakhiwo esiyinkimbinkimbi ngenxa yekhabhoni ephezulu, yenze iiflake zegraphite okanye iinodule. Ukuqiniswa kwee-alloys zetsimbi kubandakanya ukubunjwa kwe-austenite dendrites, eguqulwa ibe yi-ferrite kunye ne-pearlite ekupholiseni. Izinga lokupholisa kunye nokubunjwa kwe-alloy kuchaphazela kakhulu ukwakheka kweenkozo kunye neempawu zomatshini zokuphosa.

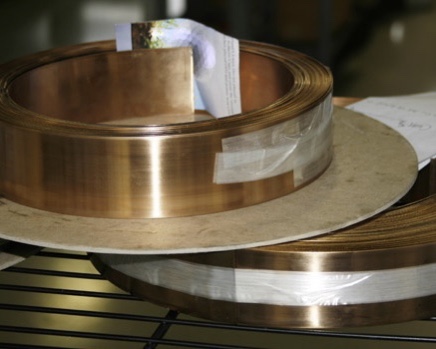

Iialloyi zobhedu: I-alloys zethusi, ezifana nobhedu kunye nobhedu, ziqiniswe nge-columnar okanye i-equiaxed grain structure. Ezi ngxube zilungele ukuhlukana, apho izinto ezihlukeneyo kwi-alloy zihlukana ngexesha lokuqiniswa, okukhokelela ekuhlukeni kokubunjwa kunye neepropati ngaphakathi kwe-casting.

Ubudlelwane phakathi koBumbano kunye noMgangatho wokuCasa

Ukuziphatha kokuqina kwealloyi kuchaphazela ngokuthe ngqo umgangatho wokusalwa. Inkqubo yokuqinisa efanayo kunye nokulawulwayo ibalulekile ukunciphisa iziphene ezifana ne-porosity, ulwahlulo, kunye nokukrazula okushushu. Ngokomzekelo, ukupholisa ngokukhawuleza kunokukhokelela ekubunjweni kweenkozo ezintle, ukuphucula iimpawu zomatshini zokuphosa. Ngakolunye uhlangothi, ukupholisa okucothayo kunokubangela iinkozo ezirhabaxa kunye nokwanda kokuchaphazeleka kwiziphene.

Ixesha lokuqinisa kunye nesantya

Ixesha lokuqiniswa kunye nesantya ziphenjelelwa zizinto ezifana nobukhulu bokuphosa, imilo, kunye neempawu ze-thermal ze-mold material. Ixesha lokuqiniswa lixesha elifunekayo ukuze konke ukuphosa kwinguqu ukusuka kulwelo ukuya kwinto eqinileyo, ngelixa isantya sokuqina sibhekisa kwisantya esenzeka ngalo olu tshintsho.

Izantya ezikhawulezayo zokuqinisa zifikelelwa ngokubanzi ngobuchule obufana nokusebenzisa imibumbo ebandayo, ekhupha ngokukhawuleza ubushushu kwisinyithi esinyibilikisiweyo. Oku kubangela ubume obucolekileyo obuziinkozo kunye nokuphuculwa kweempawu zoomatshini. Nangona kunjalo, ukupholisa ngokukhawuleza ngokukhawuleza kunokukhokelela kuxinzelelo lwe-thermal kunye nokuqhekeka. Ke ngoko, ukuzuza ulungelelwaniso olufanelekileyo phakathi kwesantya sokuqina kunye nomgangatho wokuphosa kubalulekile.

Ixesha lokuposa: Oct-11-2024