| Iimboniselo eziKhawulezayo zeAustenitic Stainless Steel | |

| Ukuqulunqwa kweMichiza ePhambili | Cr, Ni, C, Mo, Cu, Si, Nb, Ti |

| Ukusebenza | I-non-magnetic, ukuqina okuphezulu, iplastiki ephezulu, amandla aphantsi |

| Ingcaciso | Insimbi engenasici kunye nesakhiwo se-austenitic kwiqondo lokushisa |

| ABangameli abameleyo | 304, 316, 1.4310, 1.4301, 1.4408 |

| Ubuchule | Mhle |

| Ukuweldability | Ngokubanzi kakuhle kakhulu |

| Ukusetyenziswa okuqhelekileyo | Oomatshini bokutya, i-Hardware, i-Chemical Processing... njl |

Intsimbi engatyiwayo inomlinganiselo ophantsi wechromium oyi-10.5%, nto leyo eyenza ukuba ixhathise ngakumbi kwiindawo ezinolwelo ezidlekayo kunye ne-oxidation. Iyaxhathisa kwi-corrosion kwaye iyaxhathisa, ibonelela ngobuchule obubalaseleyo, kwaye yaziwa kakhulu ngenkangeleko yobuhle bayo. Utyalo-mali lwensimbi engenastainless "luyakwazi ukumelana nomhlwa" xa lusetyenziswa kwindawo elulwelo kunye nomphunga ongaphantsi kwe-1200°F (650°C) kunye "nokumelana nobushushu" xa lusetyenziswa ngaphezu kobu bushushu.

Austenitic steel stainlessibhekisela kwinsimbi engenasici kunye nesakhiwo se-austenitic kwiqondo lokushisa. I-Austenitic steel stainless steel yenye yeeklasi ezintlanu zensimbi engenasici nge-crystalline structure (kunye ne-ferritic, martensitic, duplex kunye nemvula ekhuni). Kwezinye iindawo, i-austentite steel stainless ikwabizwa ngokuba yi-300 series steel stainless steel. Xa intsimbi iqulethe malunga ne-18% ye-Cr, i-8% -25% ye-Ni, kwaye malunga ne-0.1% C, inesakhiwo esizinzile se-austenite. I-Austenitic chromium-nickel steel stainless steel iquka i-18Cr-8Ni edumileyo yentsimbi kunye ne-Cr-Ni ephezulu ye-steel series ephuhliswe ngokudibanisa i-Cr kunye ne-Nick content kunye nokongeza i-Mo, i-Cu, i-Si, i-Nb, i-Ti kunye nezinye izinto kule siseko. I-Austenitic stainless steel ayinayo imagnetic kwaye inokuqina okuphezulu kunye neplastiki, kodwa amandla ayo aphantsi, kwaye akunakwenzeka ukuwomeleza ngokuguqulwa kwesigaba. Inokuqiniswa kuphela ngokusebenza okubandayo. Ukuba izinto ezifana ne-S, i-Ca, i-Se, i-Te zongezwa, ineempawu ezintle zobuchule.

I-Austenitic steel stainless inokuvelisa i-castings. Ukuze kuphuculwe i-fluidity yensimbi etyhidiweyo kunye nokuphucula ukusebenza kokuphosa, ukubunjwa kwe-alloy yensimbi etyhidiweyo kufuneka kulungiswe ngokunyusa umxholo we-silicon, ukwandisa uluhlu lwe-chromium kunye nomxholo we-nickel, kunye nokwandisa umda ophezulu we-sulfure element yokungcola.

I-Austenitic stainless steel kufuneka ibe sisombululo esiqinileyo phambi kokusetyenziswa, ukuze kwandiswe isisombululo esiqinileyo se-precipitates ezahlukeneyo ezifana ne-carbides kwintsimbi kwi-matrix ye-austenite, ngelixa i-homogenizing isakhiwo kunye nokuphelisa uxinzelelo, ukuze kuqinisekiswe ukuxhathisa okugqwesileyo kwe-Corrosion kunye iimpawu zoomatshini. Inkqubo echanekileyo yonyango lwesisombululo kukupholisa amanzi emva kokufudumeza kwi-1050~1150℃ (iindawo ezibhityileyo zinokupholiswa ngumoya). Iqondo lokushisa lonyango lwesisombululo lixhomekeke kwiqondo le-alloying yentsimbi: I-Molybdenum-free okanye i-low-molybdenum imigangatho yentsimbi kufuneka ibe ngaphantsi (≤1100℃), kunye namabakala aphezulu alloyed afana ne-00Cr20Ni18Mo-6CuN, 00Cr25Ni22Mo2N, njl. 1080~1150) ℃).

I-Austenitic 304 ipleyiti yensimbi engenasici, ekuthiwa izisa i-anti-rust eyomeleleyo kunye nokumelana nomhlwa, kwaye ineplastiki egqwesileyo kunye nokuqina, ekulungele ukunyathela kunye nokwenza. Ngoxinaniso lwe-7.93 g / cm3, i-304 insimbi engenasici yinto eqhelekileyo kakhulu, eyaziwa ngokuba yi-18/8 yensimbi engenasici kwishishini. Iimveliso zayo zetsimbi ziyamelana nobushushu obuphezulu kwaye zineempawu ezintle zokucwangcisa, ngoko ke zisetyenziswa kakhulu kwishishini kunye nefenitshala yokuhombisa amashishini kunye nokutya kunye namashishini onyango.

IBanga eliLinganayo leNtsimbi eNgatyiwayo | |||||||

| Iindidi | AISI | I-W-stoff | I-DIN | BS | SS | UNE / IHA | I-UNI |

| Intsimbi yentsimbi yeMartensitic kunye neFerritic | 420 C | 1.4034 | X43Cr16 | ||||

| 440 B/1 | 1.4112 | X90 Cr Mo V18 | |||||

| - | 1.2083 | X42 Kr 13 | - | 2314 | F.5263 | - | |

| 403 | 1.4000 | X6Cr13 | 403 S 17 | 2301 | F.3110 | X6Cr13 | |

| (410S) | 1.4001 | X7 Kr 14 | (403 S17) | 2301 | F.3110 | X6Cr13 | |

| 405 | 1.4002 | X6 CrAl 13 | 405 S 17 | - | F.3111 | X6 CrAl 13 | |

| 416 | 1.4005 | X12 CrS 13 | 416 S 21 | 2380 | F.3411 | X12CrS13 | |

| 410 | 1.4006 | X 10 Kr 13 | 410 S21 | 2302 | F.3401 | X12Cr13 | |

| 430 | 1.4016 | X6 Kr 17 | 430 S 17 | 2320 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | X20 Cr 13 | 420 S 37 | 2303 | F.3402 | X20Cr13 | |

| 420F | 1.4028 | X30 Cr 13 | 420 S 45 | (2304) | F.3403 | X30Cr13 | |

| (420) | 1.4031 | X39Cr13 | 420 S 45 | (2304) | F.3404 | - | |

| 431 | 1.4057 | X20 CrNi 17 2 | 431 S 29 | 2321 | F.3427 | X16CrNi16 | |

| 430F | 1.4104 | X12 CrMoS 17 | - | 2383 | F.3117 | X10CrS17 | |

| 434 | 1.4113 | X6 CrMo 17 | 434 S17 | 2325 | - | X8CrMo17 | |

| 430Ti | 1.4510 | X6 CrTi 17 | - | - | - | X6CrTi17 | |

| 409 | 1.4512 | X5 CrTi 12 | 409 S 17 | - | - | X6CrTi12 | |

| Intsimbi yeAustenitic engatyiwa | 304 | 1.4301 | X5 CrNi 18 9 | 304 S 15 | 2332 | F.3551 | X5CrNi18 10 |

| 305 | 1.4303 | X5 CrNi 18 12 | 305 S 19 | - | - | X8CrNi19 10 | |

| 303 | 1.4305 | X12 CrNiS 18 8 | 303 S 21 | 2346 | F.3508 | X10CrNiS 18 09 | |

| 304L | 1.4306 | X2 CrNiS 18 9 | 304 S 12 | 2352 | F.3503 | X2CrNi18 11 | |

| 301 | 1.4310 | X12 CrNi 17 7 | - | 2331 | F.3517 | X12CrNi17 07 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2332 | F.3551 | X5CrNi18 10 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2333 | F.3551 | X5CrNi18 10 | |

| 304LN | 1.4311 | X2 CrNiN 18 10 | 304 S62 | 2371 | - | - | |

| 316 | 1.4401 | X5 CrNiMo 18 10 | 316 S16 | 2347 | F.3543 | X5CrNiMo17 12 | |

| 316L | 1.4404 | - | 316 S 12/13/14/22/24 | 2348 | X2CrNiMo17 12 | ||

| 316LN | 1.4429 | X2 CrNiMoN 18 13 | - | 2375 | - | - | |

| 316L | 1.4435 | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24 | 2353 | - | X2CrNiMo17 12 | |

| 316 | 1.4436 | - | 316 S 33 | 2343 | - | X8CrNiMo 17 13 | |

| 317L | 1.4438 | X2 CrNiMo 18 16 | 317 S 12 | 2367 | - | X2CrNiMo18 16 | |

| 329 | 1.4460 | X3 CrNiMoN 27 5 2 | - | 2324 | F.3309 | - | |

| 321 | 1.4541 | X10 CrNiTi 18 9 | 321 S 12 | 2337 | F.3553 | X6CrNiTi18 11 | |

| 347 | 1.4550 | X10 CrNiNb 18 9 | 347 S 17 | 2338 | F.3552 | X6CrNiNb18 11 | |

| 316Ti | 1.4571 | X10 CrNiMoTi 18 10 | 320 S 17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 | X15 CrNiSi 20 12 | 309 S 24 | - | - | X16 CrNi 24 14 | |

| 330 | 1.4864 | X12 NiCrSi 36 16 | - | - | - | - | |

| Duplex Steel engatyiwa | S32750 | 1.4410 | X 2 CrNiMoN 25 7 4 | - | 2328 | - | - |

| S31500 | 1.4417 | X 2 CrNiMoSi 19 5 | - | 2376 | - | - | |

| S31803 | 1.4462 | X 2 CrNiMoN 22 5 3 | - | 2377 | - | - | |

| S32760 | 1.4501 | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 | X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

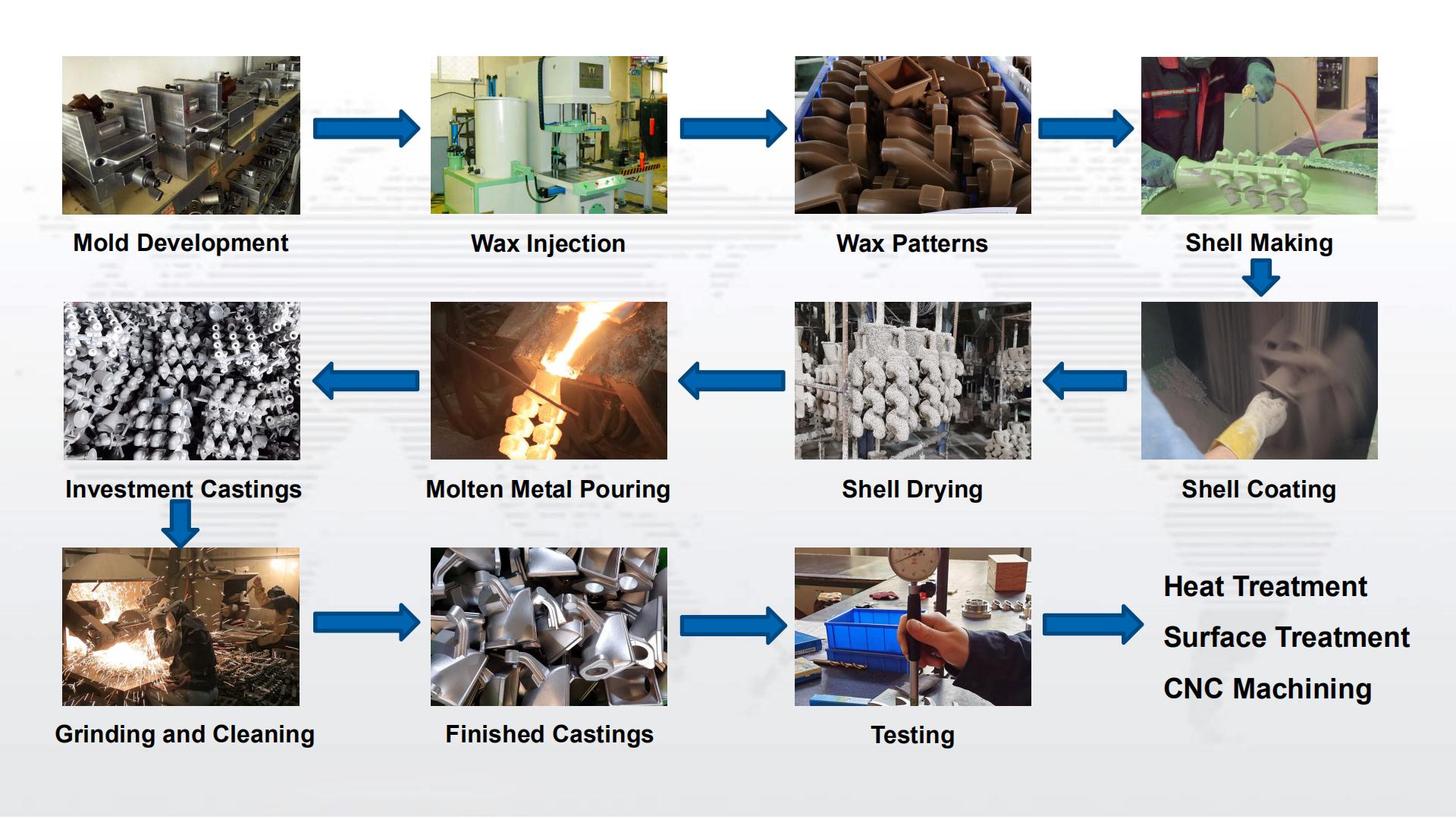

Izixhobo ze-Frerous kunye ne-Non-ferrous for Investment Casting, iLast Wax Casting Inkqubo:

- • Intsimbi engwevu: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

- • I-Ductile Iron okanye i-Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

- • Intsimbi yeCarbon: AISI 1020 - AISI 1060, C30, C40, C45.

- • I-Steel Alloys: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo...etc ngesicelo.

- • I-Stainless Steel: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 kunye nezinye ibakala lensimbi engenasici.

- • Ubhedu, ubhedu olubomvu, uBronze okanye ezinye iintsimbi ezisekelwe kwi-Copper: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

- • Ezinye iiMathiriyeli ngokweemfuno zakho ezizodwa okanye ngokwe-ASTM, SAE, AISI, ACI, DIN, EN, ISO, kunye nemigangatho yeGB

Usetyenziso lweSiko lokuCasa kunye naMacandelo oMatshini:

- 1. Amacandelo e-Automobile: i-Brake Disc, i-Connect Rod, i-Axle ye-Drive, i-Shaft ye-Drive, i-Arm yokulawula, i-Gearbox Housing, i-Gearbox Cover, i-Clutch Cover, i-Clutch Housing, i-Wheels, i-Filter Housing, i-CV Joint Housing, i-Lock Hook.

- 2. Amacandelo eLori: Iingalo ze-Rocker, i-Gearbox yoThutho, i-Axles ye-Drive, i-Gear Housing, i-Gear Cover, i-Towing Eye, i-Connect Rod, i-Engine Block, i-Engine Cover, i-Joint Bolt, i-Power Takeoff, i-Crankshaft, i-Camshaft, i-Oil Pan.

- 3. Amacandelo e-Hydraulic: I-Hydraulic Cylinder, i-Hydraulic Pump, i-Gerotor Housing, i-Vane, i-Bushing, i-Tank ye-Hydraulic, i-Hydraulic Cylinder Head, i-Hydraulic Cylinder Triangle Bracket.

- 4. Oomatshini boLimo kunye neeNdawo zeTrektara: Izindlu zeGear, i-Gear Cover, i-Connect Rod, i-Torque Rod, iBlokhi ye-injini, i-Engine Cover, i-Oil Pump Housing, i-Bracket, i-Hanger, i-Hook, i-Bracket.

- 5. Izitimela zikaloliwe kunye neemoto zoThutho: I-Shock Absorber Housing, i-Shock Absorber Cover, i-Draft Gear Housing, i-Draft Gear Cover, i-Wedge kunye ne-Cone, i-Wheels, i-Brake Systems, i-Handles, i-Guids.

- 6. Amacandelo oomatshini bokwakha: I-Gear, i-Bearing Seat, i-Gear Pump, i-Gearbox Housing, i-Gearbox Cover, i-Flange, i-Bushing, i-Boom Cylinder, i-Support Bracket, i-Tank ye-Hydraulic, i-Bucket Teeth, i-Bucket.

- 7. Amacandelo eZixhobo zoLungiselelo: Iivili, iCaster, iBracket, i-Hydraulic Cylinder, i-Forklift Spare Parts, i-Lock Case.

- 8. I-Valve kunye nePump Parts: I-Valve Body (Izindlu), i-Butterfly Valve Disc, i-Ball Valve Housing, i-Flange, i-Connector, i-Camlock, i-Impeller evulekile, i-Impeller yokuvala, i-Pump Housing (umzimba), i-Pump Cover.

UNyango loBubushushu lwe-AISI 316 yokuSasa ngeNtsimbi eStainless:

Ukushisa kwi-1900 ° F (1040 ° C) ubuncinane, ukubamba ixesha elaneleyo, ukucima emanzini okanye ukupholisa ngokukhawuleza ngezinye iindlela. I-AISI 316 ilingana neCF8M/F316 kunye ne-Chinese Standard 0Cr17Ni12Mo2. I-AISI 314 yimolybdenum ethwele ukuguqulwa kwe-AISI 304 ingxubevange kwaye ilingana nentsimbi ye-CF8M eyenziwe ngentsimbi. Ubukho be-molybdenum kwandisa ukuxhathisa kokutya kunye nokuchasana nokugoba ngeekloridi. I-alloy isetyenziselwa kwiimeko ezinobumuncu kunye ne-alkaline kunye nokuphatha i-citric, i-oxalic kunye ne-phosphoric acids.