Intsimbi yokuphosa, eyona nto igquma intsimbi engwevu, intsimbi, intsimbi ecoliweyo, intsimbi ecoliweyo kunye nenye intsimbi ephezulu, isetyenziswa kakhuluRMC Casting Foundry. I-cast iron castings idlala indima ebalulekileyoamashishini anamhlanje. Ukukhetha iinkqubo ezichanekileyo kunye nezifanelekileyo zokuphosa ezenziwe ngentsimbi yentsimbi kuya kukunceda ukuba ufumane i-iron castings ngeendleko eziphantsi kunye nexesha elifutshane lokukhokela.

Apha koku kulandelayo siphakamisa imigaqo ethile okanye imiba xa sikhethaiinkqubo ezifanelekileyo zokuphosakwizinto ezityhidiweyo zentsimbi. Ngokubanzi, eyona nkqubo isetyenziswa kakhulu yokuphosa intsimbi kukugalela isanti, ilandelwa ziindlela ezikhethekileyo zokugalela, ezinje ngokwenziwa kwesinyithi, ukuphosa utyalo-mali, ukubunjwa kweqokobhe,ukuphosa amagwebukunye ne-vacuum casting.

1- Ukuphosa kweSanti kufuneka kube luKhetho lokuQala

Ikakhulu ngenxa yeendleko eziphantsi kunye nemveliso elula yeinkqubo yokugalela isanti, ukuchithwa kwesanti kuthathe malunga ne-60% ukuya kwi-70% yemveliso yokuphosa iyonke, kwaye malunga ne-70% yayo i-santi eluhlaza. Xa isanti eluhlaza ayikwazi ukuhlangabezana neemfuno kwaye ngoko unokuqwalasela ukusetyenziswa kwesanti eyomileyo okanye enye isanti. Uluhlu lobunzima bokuphosa isanti eluhlaza ukusuka kwiikhilogram ezininzi ukuya kumakhulu eekhilogram, ngelixa ukuveliswa kodongwe olomileyo kunobunzima beetoni ezininzi.

Inkqubo yokugalela isanti isebenzisa iintlobo zesanti ukwenza ukubunjwa kokubunjwa. Inokwahlulwa ibe ziindidi ezintathu:

1) Ukuphosa kweSanti eluhlaza, esebenzisa isanti emanzi (eluhlaza) ukwenza umngundo.

2) I-Resin efakwe kwiSanti yokuCasakunye No-Bake Sand Mold Casting (Ukuziqinisa kweResin Sand Casting), ezisebenzisa izinto ezidityanisiweyo zeekhemikhali ukunceda ukwenza iinkqubo zokubumba.

3) Ukuphosa kweSanti eyomileyo, esetyenziswa ikakhulu owomileyo ngaphandle kweekhemikhali zokubumba. Inkqubo yokuphosa isanti eyomileyo ibhekiselele ekulahlekeni kwegwebu elilahlekileyo kunyeukugalela ngevacuum.

Ngokuqhelekileyo, kwi-casting yentsimbi ephakathi kunye nenkulu, ukugaywa kwesanti ye-resin yokuziqinisa kuya kuba yinto efanelekileyo. Kodwa malunga nentsimbi yealloyi kunye ne-carbon steel materials, sinokukhetha isanti yeglasi yamanzi. Oku kunokufumana imilinganiselo echanekileyo, umphezulu ogudileyo we-castings, ngelixa iindleko eziphantsi kunenkqubo yokuphosa i-silica sol.

Ukuchaneka, ukugqitywa kwendawo, ubuninzi bezinto eziphathekayo kunye ne-microstructure, iipropati zomatshini azikwazi ukufikelela kwii-requriemenets ezingqongqo ukuba unokulindela okukhethekileyo kunye nokuphezulu. Kule meko, ezinye iindlela zokuphosa ezifana ne-silica sol okanye i-glass ye-investment casting, ukuphosa ukufa, ukuphosa uxinzelelo oluphantsi, ukuphosa amagwebu alahlekileyo kunye nokukhutshwa kwe-vacuum kufuneka kuthathwe emehlweni ethu.

2- Cinga ngeMfuno yoNyaka

Ukuba imfuno yakho yonyaka iphezulu, umgca wokubumba ozenzekelayo kufuneka ube lolona khetho lungcono ngenxa yomthamo omkhulu wemveliso kunye nomgangatho ozinzileyo. Kwaye le ndlela inokufikelela kumlinganiselo ophantsi weendleko kuphela ukuba isixa esifunekayo sikhulu ngokwaneleyo. Ngelixa, ukubumba ngesandla kuya kusindisa iindleko zakho ukuba ubungakanani bakho abukho bukhulu kangako, okanye izinto ozifunayo zokusaswa zinobungakanani obuphakathi okanye ubungakanani obukhulu.

Nangona kunjalo, ukubunjwa kwesanti ye-resin (ukubumba iqokobhe) inkqubo yokuphosa ikwafanelekile kwintsimbi yobukhulu obukhulu. Ngaphaya koko, ukuphoswa kweqokobhe kunokugqiba okungcono kunye nomgangatho ophezulu emva kweenkqubo zokuphosa isanti eluhlaza.

Ezinye iinkqubo ezinjengoxinzelelo oluphantsi lokuphosa ukufa, ukuphosa ukufa, ukuphosa kwi-centrifugal kulungele kuphela imveliso yobuninzi ngobuninzi ngenxa yezixhobo ezibiza kakhulu kunye nezixhobo zokusebenza.

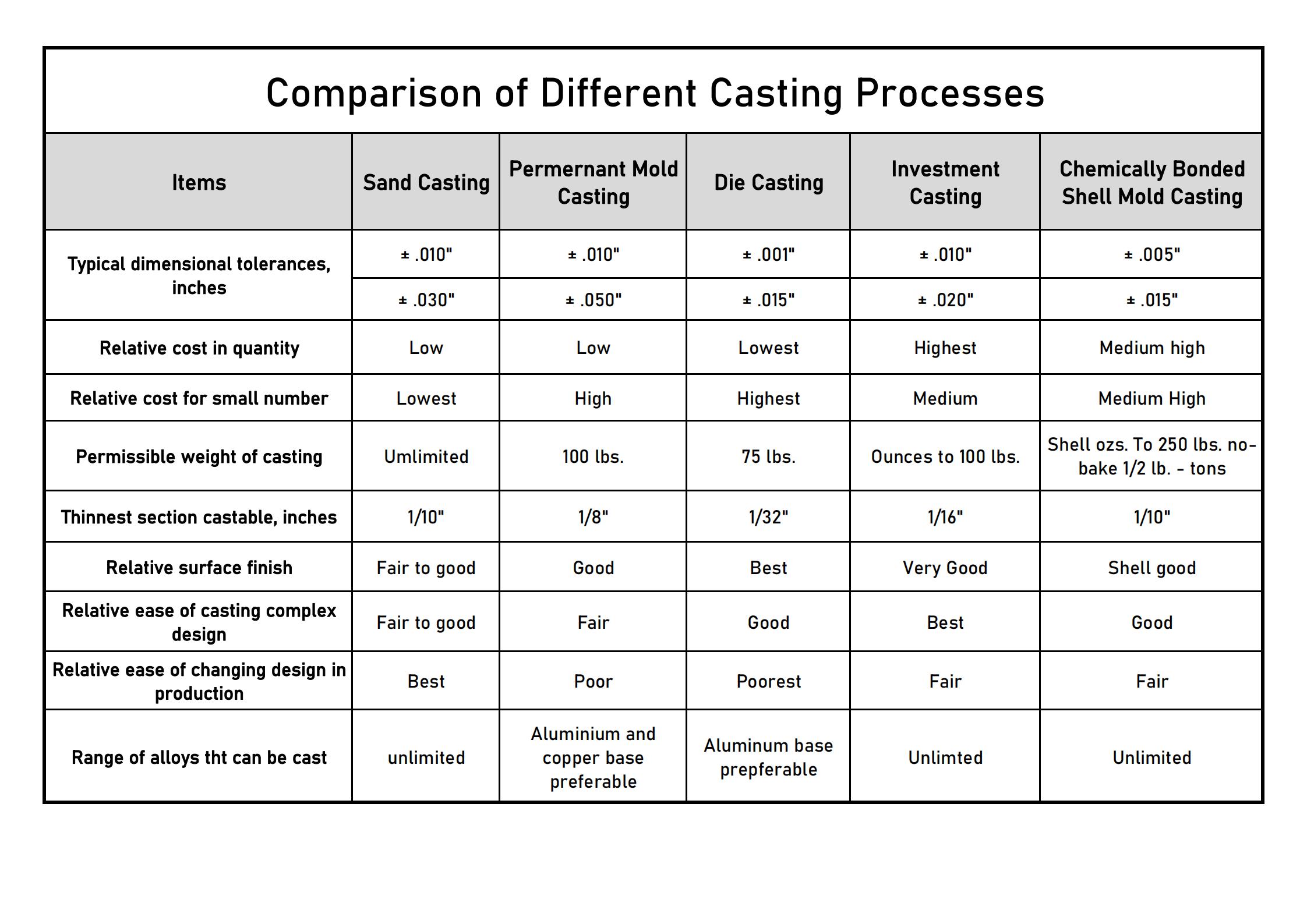

3- Ukunyamezelwa kweDimensional kunye nokubalwa koMgangatho woMgangatho

Kwinkqubo yokukhetha inkqubo yokuphosa kwi-cast iron material, ukuchaneka kwe-dimensional kunye nomgangatho womphezulu nazo zibalulekile. Ukukhetha ainkqubo yokuphosa echanekileyoiya kunciphisa imfuno yomatshini, nangaphandle komatshini. Oku kufuna uqwalaselo olubanzi lwebhalansi phakathi kokunyuka kweendleko zokuphosa kunye nokunciphisa umatshini. Ngokusekwe kwiminyaka yethu emininzi yamava, iinjineli zenkampani yethu zinokukukhethela eyona nkqubo ifanelekileyo kunye neyoqoqosho.

Ixesha lokuposa: Jan-28-2021