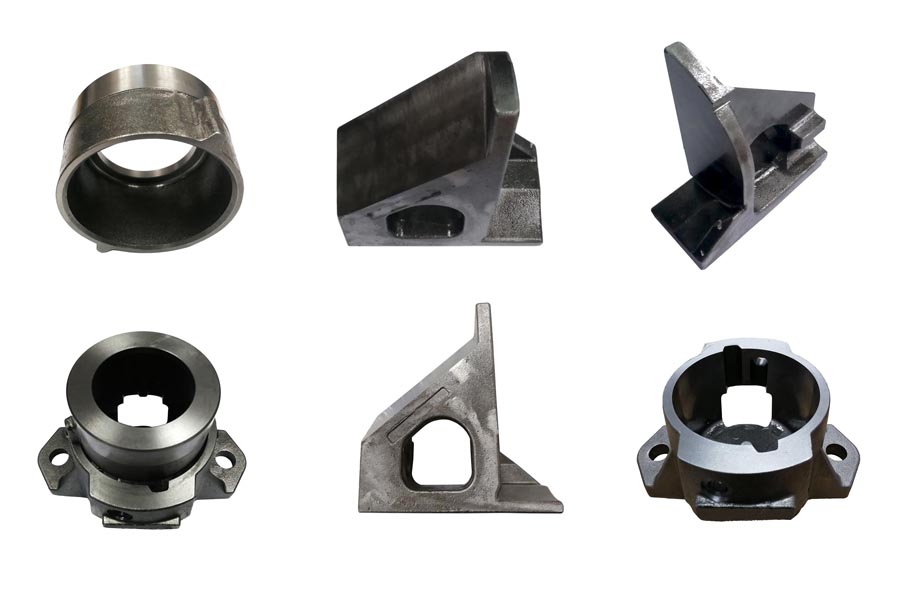

Kwi-RMC Casting Foundry, samkela iintlaka egqunywe ngundo isanti(akukho kubhaka kunye nenkqubo yokuziqinisa) ukuphosa ubhedu, ubhedu kunye nezinye i-alloys ezisekelwe kubhedu.

Iintsimbi zobheduzisetyenziswa ngokubanzi kwi-valve kunye nentsimi yepompo ngenxa yokusebenza kakuhle kwezinto zobhedu. Kwi-RMC Foundry, sivelisa ubukhulu becalaiicastings zobhedungokugalela isanti eluhlaza, ukugalelwa kwentlabathi egqunywe intlaka,utyalo malikunye nokuphosa okukhulu kobhedu, sikwathatha inkqubo yokuphosa ugwebu elahlekileyo kunye nenkqubo yokuphosa ivacuum. Ngokuqhelekileyo, ubhedu oluveliswa ngokusantiweyo luluhlu oluphambili kwisiseko sethu.

I-alloy yobhedu enezinki njengeyona nto iphambili yokudibanisa idla ngokubizwa ngokuba lubhedu. I-Copper-zinc i-alloy ye-binary ebizwa ngokuba yi-brass eqhelekileyo, kunye ne-ternary, i-quaternary okanye i-multi-element yobhedu eyenziwe ngokudibanisa inani elincinci lezinye izinto ngesiseko se-copper-zinc alloy ibizwa ngokuba lubhedu olukhethekileyo. I-Cast brass isetyenziselwa ukuvelisa ubhedu bokubunjwa. Ukuphoswa kobhedu kusetyenziswa kakhulu kwimveliso yoomatshini, ivalve kunye neempompo, iinqanawa, inqwelomoya, iimoto, ulwakhiwo kunye namanye amacandelo oshishino, ezithatha ubunzima obuthile kwizinto ezinzima zentsimbi ezingenayo intsimbi, zenza uthotho lobhedu oluphothiweyo.

Xa kuthelekiswa nobhedu kunye nobhedu, ukunyibilika okuqinileyo kwe-zinc kubhedu kukhulu kakhulu. Ngaphantsi kokulinganisa okuqhelekileyo kweqondo lokushisa, malunga ne-37% ye-zinc inokuchithwa kwi-copper, kwaye malunga ne-30% ye-zinc inokuchithwa kwimeko ye-as-cast, ngelixa i-tin bronze Kwimeko ye-as-cast, iqhekeza elikhulu le-solubility eqinile ye-tin. kubhedu yi-5% ukuya kwi-6% kuphela. Ubuninzi beqhezu lokunyibilika okuqinileyo kwe-aluminium yobhedu kubhedu kuphela yi-7% ukuya kwi-8%. Ngoko ke, i-zinc inesisombululo esihle esiqinileyo sokuqinisa ubhedu. Ngelo xesha, izinto ezininzi ezixutywayo nazo zinokuchithwa ngobhedu ukuya kwii-degrees ezahlukeneyo , Ukuqhubela phambili ukuphucula iimpawu zayo zemishini, ukwenzela ukuba ubhedu, ngokukodwa ubhedu obukhethekileyo buneempawu zamandla aphezulu. Ixabiso le-zinc lisezantsi kune-aluminiyam, ubhedu, kunye ne-tin, kwaye ityebile kwimithombo. Isixa se-zinc esongeziweyo kubhedu sikhulu, ngoko ke ixabiso lobhedu liphantsi kune-tin bronze kunye ne-aluminium bronze. I-Brass inoluhlu oluncinci lobushushu bokuqina, ulwelo olulungileyo, kunye nokunyibilikiswa okufanelekileyo.

Ngenxa yokuba ubhedu luneempawu ezikhankanywe ngasentla zamandla aphezulu, ixabiso eliphantsi kunye nokusebenza kakuhle kokuphosa, ubhedu luneentlobo ezininzi, imveliso enkulu kunye nesicelo esibanzi kunobhedu lwe-tin kunye ne-aluminium yobhedu kwii-alloys zobhedu. Nangona kunjalo, ukuxhathisa ukunxiba kunye nokumelana nokubola kobhedu akulunganga njengobhedu, ngakumbi ukuxhathisa ukubola kunye nokumelana nokunxiba kobhedu oluqhelekileyo kuphantsi. Kuphela xa ezinye izinto ze-alloy zongezwa ukwenza iintlobo ezahlukeneyo zobhedu olukhethekileyo, ukuxhathisa kwayo kunye nokuchasana nokusebenza kwe-corrosion kuye kwaphuculwa kwaye kwaphuculwa.

Njengohlobo lwesanti ezenza lukhuni, isanti ye-furan resin engabhakiyo isetyenziswa kakhulu ukwenza isanti engwevu yentsimbi kunye neenkqubo zokuphosa intsimbi. Umphezulu wesikhunta sesanti buya kuqiniswa kwimeko enzima emva kokutshiswa kwengubo. Ke ngoko, inkqubo yokuphosa isanti ye-furan yentlabathi ingasetyenziselwa ukuvelisa iindawo zokugalela zentsimbi ezinobukhulu obuphakathi nobukhulu, ukusuka kumashumi eekhilogram ukuya kwishumi leetoni. Ngomgangatho olungileyo womphezulu, ukunyamezelwa komgangatho ongqongqo kunye neziphene ezincinci zokuphosa, iinkqubo zokuphosa isanti ye-furan zingasetyenziselwa ukuvelisa iindawo zokuphosa ezintsonkothileyo.

I-RMC isebenzisa inkqubo yokugalelwa kwesanti ye-No-bake ukuvelisa iintsimbi zentsimbi, ukugalelwa kwentsimbi engatyiwa, ukujulwa kwentsimbi, kunye neentsimbi ezingwevu. Kwinkqubo ye-No-Bake, iimbumba zesanti zenziwe ngokhuni okanye ipateni yentsimbi. Intlabathi ye-fine-grain idibaniswe ne-resin binder kwi-mixer ye-sand-speed high-speed and then drop off kwibhokisi equkethe iphethini. Emva kwemizuzu embalwa, umxube we-sand-binder unzima kwaye isikhunta siyasuswa kwiipateni. I-Sand Cores ekudaleni isakhiwo sangaphakathi se-castings zenziwe ngokusebenzisa inkqubo efanayo ngexesha elifanayo. Emva kokuba ii-cores kunye nezibunjwa zangaphandle zihlanganiswe, zivaliwe kwaye zilungiselelwe ukuthululwa kwesinyithi. Izinto ezithile, ezifana ne-ductile iron castings, zifuna unyango olukhethekileyo lwentsimbi ngaphambi kokuthululelwa. Inkqubo yokuphosa i-No-Bake iguquguquka kakhulu njengoko ivumela ukuchithwa kwentsimbi kunye neentsimbi zetsimbi ukuba zigcinwe ukunyamezelwa okuchanekileyo ngelixa zikwazi ukuphatha ubungakanani beengxenye ukusuka kumashumi eegram ukuya kwishumi leetoni.

Amanyathelo okungabikho kweNkqubo ye-Shell yokubhaka:

Akukho kubhaka yinkqubo yokuphosa ebandakanya ukusetyenziswa kwezibophelelo zeekhemikhali ukudibanisa isanti yokubumba. Isanti igqithiselwa kwisikhululo sokugcwalisa ukungunda ukulungiselela ukuzaliswa kwesikhunta. I-mixer isetyenziselwa ukudibanisa isanti kunye ne-chemical binder kunye ne-catalyst. Njengoko isanti iphuma kumxube, isibophelelo siqalisa inkqubo yemichiza yokuqina. Le ndlela yokugcwalisa isikhunta ingasetyenziselwa kwisiqingatha ngasinye sobumba (ukumelana kunye nokudonsa). Isiqingatha somngundo ngasinye siyadityaniswa ukuze senze umngundo oqinileyo noxineneyo. I-rollover isetyenziselwa ukususa isiqingatha sokungunda kwibhokisi yepateni. Emva kokuba isanti isetyenzisiwe, i-mold wash ingafakwa. Iinqununu, ukuba zifunwa, zifakwe kwi-drag kwaye i-cope ivaliwe phezu kwee-cores ukugqiba ukubumba. Uluhlu lweemoto zokuphatha ukungunda kunye nabahambisi bahambisa ukungunda kwindawo yokugalela. Emva kokuba igalelwe, i-mold iyavunyelwa ukuba iphole ngaphambi kokuba ishukunyiswe. Inkqubo yokuvuthulula ibandakanya ukwaphula isanti ebunjiweyo kude nesanti. Ukusatywa emva koko kuqhubekeka kwindawo yokugqiba ukuphosa ukuze kususwe isinyusi, ukugqityezelwa nokugqityezelwa. Iingceba zesanti ebunjiweyo ziphinda zophulwe de intlabathi ibuyiselwe kubungakanani beenkozo. Isanti ngoku inokuphinda ibangwe ukuze iphinde isetyenziswe kwinkqubo yokuphosa okanye isuswe ukuze ilahlwe. Ukubuyiselwa kwe-thermal yeyona ndlela isebenzayo, epheleleyo yokungabikho kwesanti yokubhaka.

| Izixhobo zeShell Mold Casting kwi-RMC Foundry | |

| Isinyithi kunye neeAlloys | IBanga elidumileyo |

| Grey Cast Intsimbi | GG10~GG40; GJL-100 ~ GJL-350; |

| I-Ductile (Nodualar) Intsimbi yokuphosa | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| I-Austempered Ductile Iron (ADI) | EN-GJS-800-8, EN-GJS-1000-5, EN-GJS-1200-2 |

| Intsimbi yeCarbon | C20, C25, C30, C45 |

| Intsimbi yentsimbi | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Yenziwe ngentsimbi eshayinayo | I-Ferritic Stainless Steel, i-Martensitic Stainless Steel, i-Austenitic Stainless Steel, i-Precipitation Hardinless Steel, i-Duplex Stainless Steel |

| Iingxube zeAluminiyam | ASTM A356, ASTM A413, ASTM A360 |

| Ubhedu / i-Alloys esekwe kwiCopper | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Umgangatho: ASTM, SAE, AISI, GOST, DIN, EN, ISO, kunye ne-GB | |