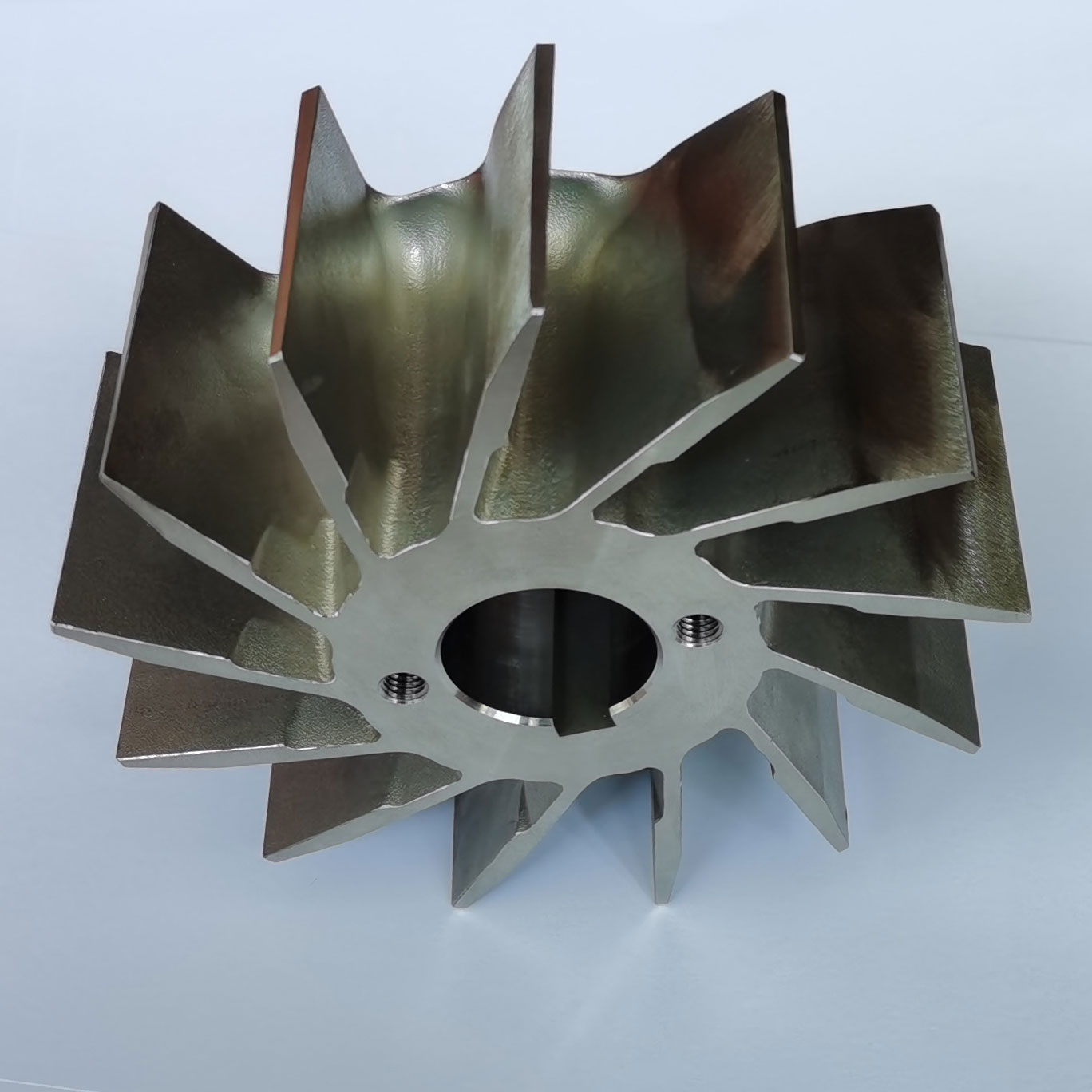

I-CF8M iphosa intsimbi engenasici evulekileyo yempompo ye-centrifugal ngokuphosa utyalo-mali,CNC Machiningkunye nokulinganisa okuguquguqukayo.

CF8M i cast austenitic steel stainless egqunywe yi ASTM A351, ASTM A743 kunye ASTM A744 umgangatho. I-CF8M ilingana ne-SS 316/F 316 kunye ne-Chinese Standard 0Cr17Ni12Mo2. I-CF8M yi-molybdenum ethwala ukuguqulwa kwe-CF8 ingxubevange kwaye ilingana nentsimbi eyenziweyo ye-AISI 316 yentsimbi. Ubukho be-molybdenum kwandisa ukuxhathisa kokutya kunye nokuchasana nokugoba ngeekloridi. I-alloy isetyenziselwa kwiimeko ezinobumuncu kunye ne-alkaline kunye nokuphatha i-citric, i-oxalic kunye ne-phosphoric acids. steel stainless CF8M ubukhulu becala iyafana SS 316, F 316 kunye TP 316. Kodwa zichazwe kwimigangatho eyahlukeneyo, kunye neempawu zabo zemichiza kunye noomatshini bahluke kancinane kakhulu. I-CF8M ichazwa kwi-ASMT A351, ASMT A743 kunye ne-ASTM A744, eyenzelwe injongo yokuphosa kuphela. I-SS 316 ichazwa kwi-ASTM A240 kunye ne-ASTM A276, yenzelwe ipleyiti, iphepha, i-strip okanye imivalo yentsimbi. Elinye ibakala libizwa ngokuba yi-F316, elisuka kwi-ASTM A182 lamalungu omgunyathi kuphela. I-TP316 iya kufumaneka kwi-ATSTM A376 yombhobho kuphela. Ezona zicelo ziphambili ze-CF8M ziphosa isigqubuthelo sensimbi engenasici: ii-impellors, ii-propellers, ii-casings zempompo, imizimba yevalvu kunye neepleyiti zokushicilela. Unyango lwesiqhelo ubushushu for CF8M luqinile Isisombululo ngokufudumeza ngaphezu 1900 °F (1040 °C), ebambe ixesha elaneleyo uze ucime emanzini okanye ukupholisa ngokukhawuleza ngezinye iindlela.

| UTyalo-mali oluNxibelela ngolwazi kwi-RMC | |

| I-R&D | Isoftware: Solidworks, CAD, Procast, Pro-e |

| Ixesha eliKhokelo loPhuhliso kunye neeSampulu: iintsuku ezingama-25 ukuya kwezingama-35 | |

| Metal etyhidiweyo | Intsimbi engatyiwa yiFerritic, intsimbi yeMartensitic,Austenitic steel stainless, Imvula iQinisa iNtsimbi eNgatyiwayo, iDuplex yentsimbi engatyiwayo |

| Intsimbi yeCarbon, intsimbi yengxubevange, intsimbi yesiXhobo, intsimbi enganyangekiyo kubushushu, | |

| Ingxubevange yeNickle-base, iAluminiyam ialloy, iCopper-base Alloy, iCobalt-base Alloy | |

| Metal Standard | ISO, GB, ASTM, SAE, GOST EN, DIN, JIS, BS |

| Izinto zokwakha zeShell | I-Silica Sol (i-Silica enamanzi) |

| Iglasi yamanzi (iSodium silicate) | |

| Imixube yeSilica Sol kunye neglasi yamanzi | |

| IParameter yobuGcisa | Ubunzima bePiece: 2 gram ukuya kwi-200 kilogram |

| Ubungakanani bobukhulu: 1,000 mm yeDiameter okanye Ubude | |

| Ubungqingqwa boDonga obuncinci: 1.5mm | |

| Ukuphosa uburhabaxa: Ra 3.2-6.4, Machining Uburhabaxa: Ra 1.6 | |

| Ukunyamezela kokuCalwa: VDG P690, D1/CT5-7 | |

| Ukunyamezela koMatshini: ISO 2768-mk/IT6 | |

| I-Inner Core: I-Ceramic Core, i-Urea Core, i-Wax ye-Wax e-Soluble yamanzi | |

| Unyango lobushushu | Ukuqhelanisa, ukufudumeza, ukucima, ukunyathela, iSisombululo, iCarburization. |

| Unyango loMphezulu | Ukuhombisa, iSanti / ukuDutyulwa kokuDutyulwa, ukuPlakwa kweZinc, ukuPlakwa ngeNickel, Unyango lwe-Oxidation, iPhosphating, ukupeyinta umgubo, iGeormet, iAnodizing |

| Uvavanyo loMda | CMM, Vernier Caliper, Ngaphakathi Caliper. I-Depth Gage, i-Height Gage, i-Go/No go gage, i-Special Fixtures |

| Ukuhlolwa kwemichiza | Uhlalutyo lwe-Chemical Compostion Analysis (20 izakhi zeekhemikhali), ukuHlolwa kokucoceka, ukuhlolwa kwe-X-ray yeRadiographic, i-Carbon-Sulfur Analyzer |

| Ukuhlolwa Ngokwasemzimbeni | Ukulinganisa okuDynamic, ukuBlansi okuNgqo, iiMpahla zoomatshini (Ubulukhuni, Amandla eSivuno, Amandla aQinisayo), Ukwandiswa |

| Isakhono seMveliso | Ngaphezu kweetoni ezingama-250 ngenyanga, ngaphezulu kweetoni ezingama-3,000 ngonyaka. |

Ukwakhiwa kweMichiza yeCF8M Cast intsimbi engatyiwa:

Ikhabhoni: 0.08 max

IManganese: 1.50 max

I-Silicon: 1.50 max

Isulfure: 0.040 max

Phosphorus: 0.040 max

I-Chromium: 18.0-21.0

I-Nickel: 9.0-12.0

I-Molybdenum: 2.0-3.0

IiPropati zoomatshini zeCF8M Cast intsimbi engatyiwayo:

Amandla okuqina: imizuzu engama-70 ksi (485 Mpa)

Amandla eSivuno: min 30 ksi (205 Mpa)

Elongation kwi-intshi ezi-2. okanye 50 mm: min 30.0%

Kutheni bebizwa ngokuba ziiCF8M?

Ngokutsho kokutyunjwa, unobumba wokuqala u-C uthetha inkonzo ekujoliswe kuyo ukuba isetyenziswe kwinkonzo yokunqanda ukubola , kodwa ngamanye amaxesha kuthetha ukusetyenziswa kwe-CASTING kuba uya kufumana i-F 316 kwi-ASTM A 350 ( F = FORGE ). Ileta yesibini F ibonisa indawo esondeleyo ye-alloy kwi-iron-chromium-nickel (FeCrNi) ternary diagram. Kubasebenzisi abaqheleneyo nomzobo, unobumba wesibini unika isalathiso se-iron yegama, i-nickel, kunye nomxholo wechromium, kodwa uninzi lwabantu kuya kufuneka lufumane ulwazi lwe-alloying olusuka kwinkcazo yemathiriyeli. Unobumba wesithathu nowesine u-8M umele owona mxholo uphezulu wekhabhoni ovumelekileyo kwiiyunithi ze-0.01% (umzekelo, i-CF8M inobuninzi be-0.08% yekhabhoni)