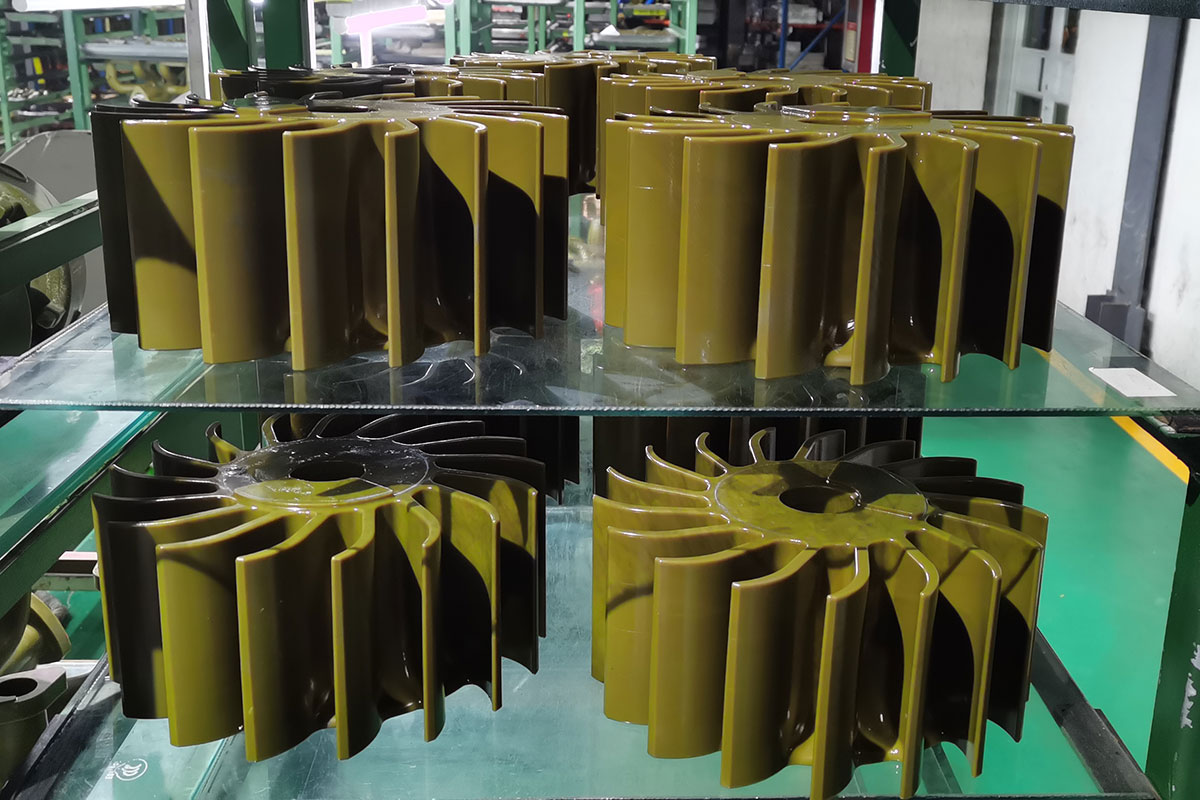

China AISI 304 Stainless Steel Investment Casting Impeller. Iinkonzo ze-OEM ezilungiselelweyo kunyeCNC MachiningZiyafumaneka.

I-Austenitic 304 ipleyiti yensimbi engenasici, ekuthiwa izisa i-anti-rust eyomeleleyo kunye nokumelana nomhlwa, kwaye ineplastiki egqwesileyo kunye nokuqina, ekulungele ukunyathela kunye nokwenza. Ngoxinaniso lwe-7.93 g / cm3, i-304 insimbi engenasici yinto eqhelekileyo kakhulu, eyaziwa ngokuba yi-18/8 yensimbi engenasici kwishishini. Iimveliso zayo zetsimbi ziyamelana nobushushu obuphezulu kwaye zineempawu ezintle zokucwangcisa, ngoko ke zisetyenziswa kakhulu kwishishini kunye nefenitshala yokuhombisa amashishini kunye nokutya kunye namashishini onyango.

I-Foundry yethu inokuvelisaisiko utyalo stainless steel castingsehambelana ngqo neenkcukacha zoyilo lwakho. Ukuphosa ukusuka kumashumi eegram ukuya kumashumi eekhilogram okanye ngaphezulu, sibonelela ngokunyamezelana okuqinileyo kunye nenxalenye engaguqukiyo ukuya kwinxalenye yokuphindaphinda.

Ngokuqhelekileyo, insimbi engenasici kufuneka iphonswe yinkqubo yokuphosa echanekileyo yotyalo-mali kunye ne-silica sol njengebhondi. Iintsimbi ze-silica sol castings zinezinga eliphezulu kakhulu lokuchaneka komphezulu kunye nokusebenza.

Ngenxa yeempawu zayo ezikhethekileyo zomzimba, i-casts stainless steel castings ithandwa kuluhlu olubanzi lwezicelo, ngakumbi ezo zikwimeko enzima. Iimarike eziqhelekileyo zotyalo-mali lwensimbi engenasici ziquka ioli kunye negesi, amandla ombane, ukuthutha, iinkqubo ze-hydraulic, imboni yokutya, i-hardware kunye nezitshixo, ezolimo ... njl.

Utyalo-mali (i-wax elahlekileyo) yokuphosa yindlela echanekileyo yokuphosa izinto ezintsonkothileyo ezikufutshane ne-net-shape iinkcukacha usebenzisa ukuphindwaphindwa kweepateni zewax. Ukuphosa utyalo-mali okanye i-wax elahlekileyo yinkqubo yokwenza isinyithi esebenzisa ipateni ye-wax ejikelezwe yiqokobhe le-ceramic ukwenza i-ceramic mold. Xa iqokobhe loma, iwax iyanyibilika, kushiyeke ukungunda kuphela. Emva koko icandelo lokuphosa lenziwa ngokuthulula isinyithi esityhidiweyo kwi-mold ceramic.

| UKUNYAMEZELA UKULAHLWA KOTYALO-MALI | |||

| I-intshi | Iimilimitha | ||

| Ubungakanani | Ukunyamezelana | Ubungakanani | Ukunyamezelana |

| Ukuya kuthi ga kwi-0.500 | ±.004" | Ukuya kuthi ga kwi-12.0 | ± 0.10mm |

| 0.500 ukuya kwi-1.000" | ±.006" | 12.0 ukuba 25.0 | ± 0.15mm |

| 1.000 ukuya 1.500” | ±.008" | 25.0 ukuba 37.0 | ± 0.20mm |

| 1.500 ukuya ku-2.000” | ±.010" | 37.0 ukuba 50.0 | ± 0.25mm |

| 2.000 ukuya 2.500” | ±.012" | 50.0 ukuba 62.0 | ± 0.30mm |

| 2.500 ukuya 3.500” | ±.014" | 62.0 ukuba 87.0 | ± 0.35mm |

| 3.500 ukuya ku-5.000" | ±.017" | 87.0 ukuba 125.0 | ± 0.40mm |

| 5.000 ukuya 7.500” | ±.020" | 125.0 ukuya ku-190.0 | ± 0.50mm |

| 7.500 ukuya 10.000” | ±.022" | 190.0 ukuba 250.0 | ± 0.57mm |

| 10.000 ukuya kwi-12.500" | ±.025" | 250.0 ukuba 312.0 | ± 0.60mm |

| 12.500 ukuba 15.000 | ±.028" | 312.0 ukuba 375.0 | ± 0.70mm |