Iimveliso zokugalela zeAluminiyam ngokweSikoinkqubo yokugalela isantikwayeCNC Machining.

Amanyathelo eNkqubo yokuVeliswa kweSanti

1. Ukwenza iipateni

I-resin okanye iipateni ze-aluminium ziya kuba yimfuneko kwinkqubo yokuphosa isanti eluhlaza. Ngaphandle kweepateni, ukuveliswa kwee-castings kuya kuba yinto engenakwenzeka. Ngamanye amaxesha, iipateni zokhuni zingasetyenziselwa imveliso encinci, kodwa ukuveliswa kobuninzi, i-resin okanye iipateni ze-aluminium ziya kufaneleka ngakumbi.

2. Inkqubo yokubumba

Ukubumba kwesanti eluhlaza kunokwenziwa ngeendlela ezintathu eziqhelekileyo, kubandakanywa ukubumba ngesandla, umatshini wokubumba kunye nezixhobo zokubumba ezizenzekelayo. I-manual yokubumba yindlela yokubumba yendabuko, kodwa isekho ngenxa yobuchule bayo bokuphosa okukhulu kwiindleko eziphantsi. Indlela yomatshini wokubumba inokusindisa abasebenzi kwaye ivelise umgangatho ongcono wokusaswa, kodwa ayikwazi ukuvelisa i-castings enkulu ngenxa yobungakanani bayo bokunciphisa iibhokisi zesanti.

3. Ukunyibilika kwentsimbi nokugalela

Ukunyibilika kunokwenziwa ngeziko lombane eliphakathi kwamaza aphakathi, anokugcina umgangatho ulungile kwaye uzinzile xa kuthelekiswa neziko lemveli.

4. Ukuqhunyiswa kweSanti kunye nokuSila

Emva kokuba intsimbi eluhlaza yentsimbi ikhutshiwe kubumba lwesanti, iya kudluliselwa kumanyathelo alandelayo okudutyulwa okanye ukudutyulwa ukuze kususwe isanti kunye neoksidi ngaphandle kweendawo zokugalela. Emva koko abaqhubi baya kunqumla, bahlambulule kwaye bagaye iintloko zesango, ukunyuka, imigca yokuqhawula kunye neentambo ezibukhali.

Ukuqhubela phambili okunjengonyango lobushushu, ukuchaneka komatshini kunye nonyango lwangaphezulu kuya kuqhutywa ukuba imizobo okanye abasebenzisi bokuphela bafuna.

I-aluminiyam kunye neealloyi zayo zinokuphoswa kwaye zigalelwe ngoxinzelelo oluphezulu lokufa, ukuphoswa koxinzelelo oluphantsi, ukuphosa umxhuzulane, ukuphosa isanti, ukuphosa utyalo-mali kunyeukuphosa amagwebu. Ngokwesiqhelo, ukujulwa kwe-aluminium alloy kunobunzima obuncinci kodwa kunobume obuntsonkothileyo kunye nomphezulu ongcono.

Yiyiphi iAluminiyam alloy esiyiphosayo ngeNkqubo yokuCasa isanti:

• Cast iAluminiyam iAluminiyam ngokweMigangatho yaseTshayina: ZL101, ZL102, ZL104

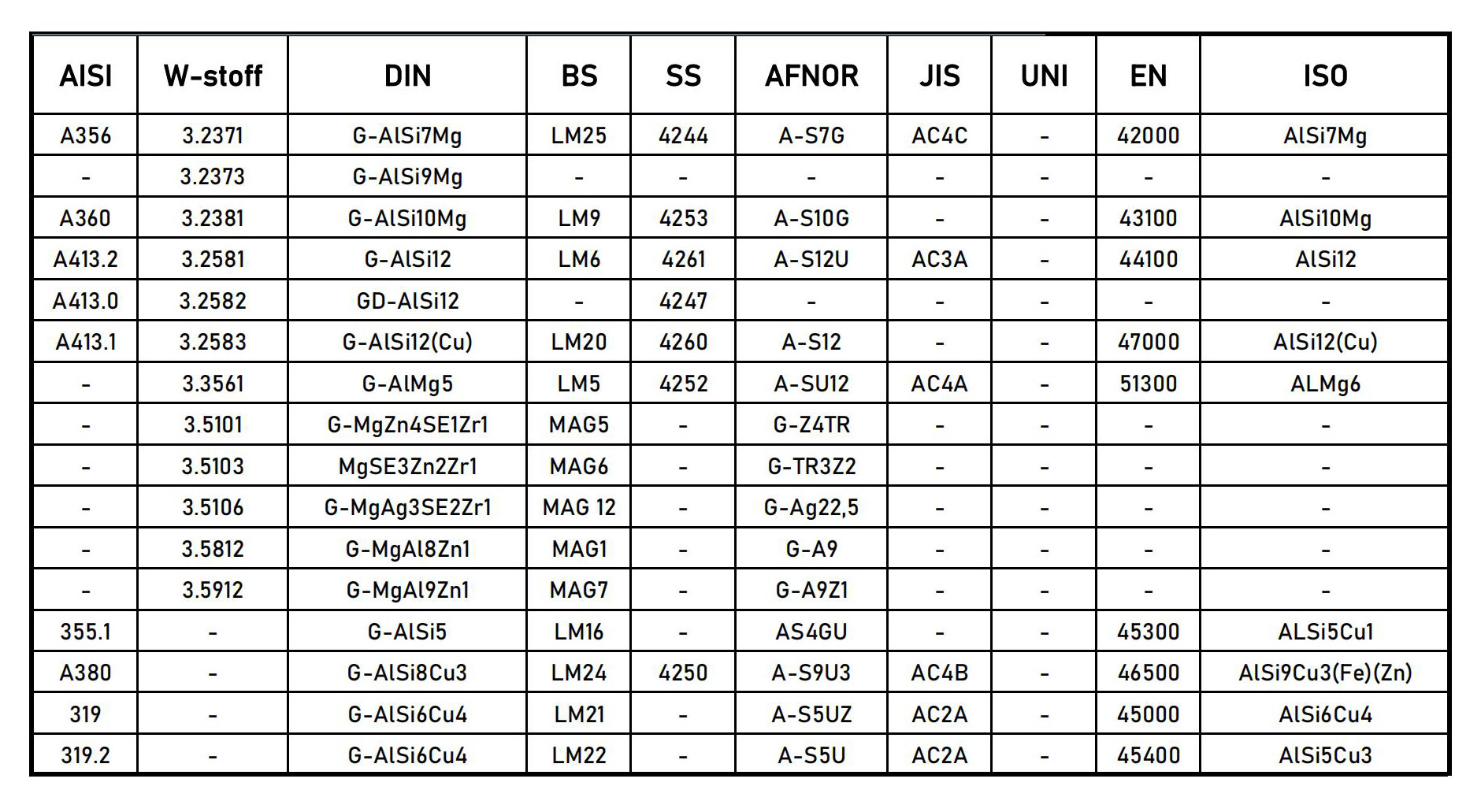

• Cast iAluminiyam iAluminiyam yi-USA Stardard: ASTM A356, ASTM A413, ASTM A360

• Cast iAluminiyam iAluminiyam ngezinye iiStarndards: AC3A, AC4A, AC4C, G-AlSi7Mg, G-Al12

| Kumanyene | Umbutho weAluminiyam | Ubunzima BHN | Amandla okuqina okugqibela, iMPa | Amandla eSivuno, iMPa | Modulus of elasticity, GPa | Ukukhathala Amandla, MPa |

| A03550 | AA355.0 | 75-105 | 255 | 185 | 70.3 | 69.0 |

| A03600 | AA360.0 | 75.0 | 300 | 170 | 71.0 | 138.0 |

| A03800 | AA380.0 | 80.0 | 317 | 159 | 71.0 | 138.0 |

| A03830 | AA383.0 | 75.0 | 310 | 152 | / | 145.0 |

| A03840 | AA384.0 | 85.0 | 331 | 165 | / | 140.0 |

| A03900 | AA390.0 | 120.0 | 280 | 240 | 81.2 | 140.0 |

| A04130 | AA413.0 | 80.0 | 296 | 145 | 71.0 | 130.0 |

| A04430 | AA443.0 | 30-60 | 145 | 48.3 | 71.0 | / |

| A05180 | AA518.0 | 80.0 | 310 | 193 | 69.0 | 160.0 |

Izinto eziluncedo kwiAluminiyam yealloy Castings:

• Ukusebenza kwentsimbi kuyafana nokwentsimbi, kodwa iipropathi zomatshini ezihambelanayo ziyancipha ngakumbi njengoko ubukhulu bodonga bukhula.

• Ubukhulu bodonga lweecastings akufunekanga bube bukhulu kakhulu, kwaye ezinye iimpawu zesakhiwo zifana nezo zentsimbi.

• Ubunzima obulula kodwa obuntsonkothileyo besakhiwo

• Iindleko zokuphosa ngekhilogram yee-aluminiyam zokusahlela ziphezulu kunezo zentsimbi kunye neentsimbi.

• Ukuba iveliswe ngenkqubo yokuphosa, iindleko zokungunda kunye nepateni ziya kuba phezulu kakhulu kunezinye iinkqubo zokusasa. Ke ngoko, ukujulwa kwe-aluminiyam yokufa kuya kulungeleka ngakumbi ukujulwa kobuninzi obufunwayo.

| Ubume boMchiza obuqhelekileyo boTyalo-mali lokuphosa iAluminiyam iAluminiyam ngeNgcaciso yaseMntla Melika | ||||||||||||||

| IBanga le-alloy | Inkcazo | Al | Cu | Si | Zn | Mg | Cr | Fe | Mn | Ti | Ag | Be | Ni | P |

| I-A356-T6 | I-AMS 4218 | UBhal | 0.20 | 6. 5 - 7. 5 | 0.10 | 0.25-0.45 | - | 0.20 | 0.10 | 0.20 | - | -- | - | - |

| A 357 | I-AMS 4219 | UBhal | 0.20 | 6. 5 - 7. 5 | 0.10 | 0.40-.70 | - | 0.20 | 0.10 | 0.04-0.20 | - | 0.04-0.07 | - | - |

| F 357 | I-AMS 4289 | UBhal | 0.20 | 6.5-7.5 | 0.10 | 0.40-.70 | - | 0.10 | 0.10 | 0.04-0.20 | - | 0.002 | - | - |

| E357 | I-AMS 4288 | UBhal | - | 6.5-7.5 | 0.10 | 0.55-0.60 | - | 0.10 | 0.10 | 0.10-0.20 | - | 0.002 | - | - |

| A201 | I-AMS 4229 | UBhal | 4.0-5.0 | 0.05 | - | 0.15-0.35 | - | 0.10 | 0.20-0.34 | 0.15-0.35 | 0.40-1.0 | - | - | - |

| C355 | I-AMS 4215 | UBhal | 1.0-1.5 | 4.5-5.5 | 0.10 | 0.40-0.60 | - | 0.20 | 0.10 ubuninzi | 0.20 | - | - | - | - |

| A206 | I-AMS 4235 | UBhal | 4.2-5.0 | .05ubuninzi | 0.05 ubuninzi | 0.20-0.35 | - | 0.10ma | 0.20-0.50 | 0.15-0.30 | - | - | 0.5 ubuninzi | - |

| B206 | UBhal | 4.2-5.0 | .05ubuninzi | 0.05 ubuninzi | 0.15-0.35 | - | 0.10 ubuninzi | 0.20-0.50 | 0 10 | - | - | 0.5 ubuninzi | - | |