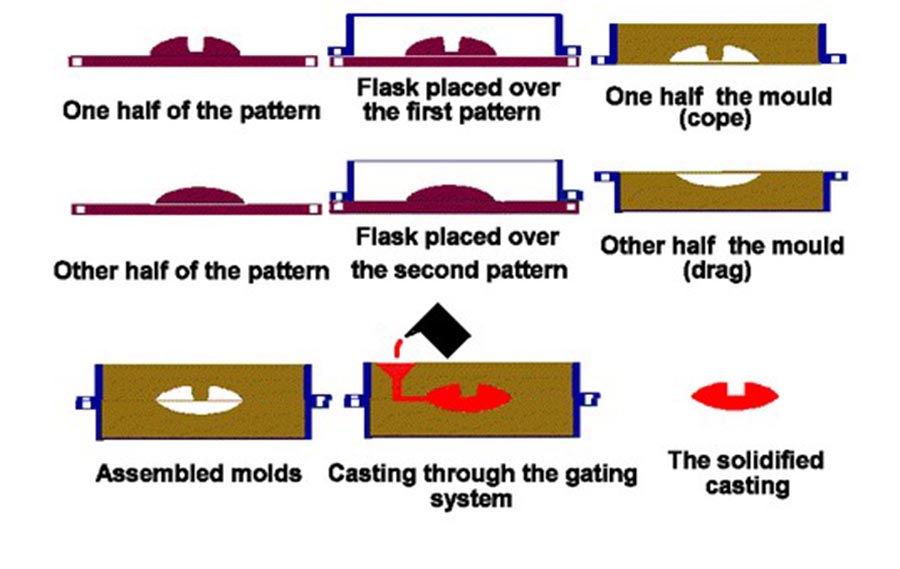

Isiseko sesanti yisiseko sesinyithi esisetyenziswa ikakhulu inkqubo yokugalela isanti ukuvelisaiintsimbi zentsimbiyenziwe ngentsimbi engwevu, intsimbi edityanisiweyo, intsimbi ephoswe ngentsimbi, intsimbi engatyiwa, ubhedu kunye nealloys.Inkqubo yokugalela isantiisetyenziselwa ikakhulu ukuvelisa iintsimbi ezingwevu kunye nentsimbi yokuphosa. Inokwahlulwa ibe yintlabathi eluhlaza, i-furan resin esanti eqatywe ngaphambili (ukubumba iqokobhe) ukugalela ngokusekelwe kwizinto ezahlukeneyo zesanti. Ukuphoswa kwesanti yentsimbi kunezibonelelo ezininzi ezinje ngeendleko eziphantsi, uyilo oluntsonkothileyo, ukusebenza kakuhle, kunye nomgangatho olungileyo. Inkqubo yokuphosa isanti lukhetho olufanelekileyo kunye nolulungileyo lweendawo zokuphosa intsimbi ngaphandle kokuba iimfuno ezikhethekileyo okanye eziphezulu kakhulu kufuneka zihambelane.

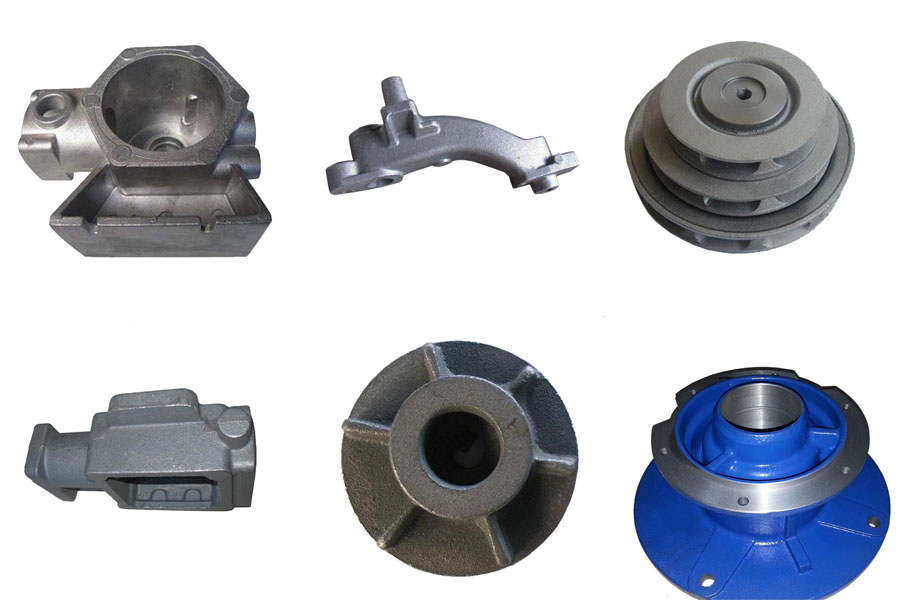

I-RMC Foundry inokugalela iintsimbi zentsimbi isebenzisa ukubunjwa kwesanti eluhlaza,iqokobhe lobushushu ngundokunye nenkqubo yokuphosa yokungabhaki ukuya kuthi ga kwiitoni zobunzima obugqityiweyo kwintsimbi engwevu kunye nentsimbi yokuphosa, ukuya kuthi ga kumakhulu eekhilogramiintsimbi zentsimbikunye neecasts steel stainless. I-RMC inokuvelisa iinxalenye zokuphosa kwiintlobo ngeentlobo zemathiriyeli, kubandakanya intsimbi engwevu, intsimbi yentsimbi,yenziwe ngentsimbi eshayinayo, intsimbi yekhabhoni, insimbi engagugiyo, kunye nentsimbi ekwazi ukumelana nobushushu esekelwe kwimigangatho eyahlukeneyo evela eChina naphesheya kolwandle.

Amava e-RMC Foundry ekudaleni ukukhutshwa kwesanti ephezulu ukusuka kwimathiriyeli yodidi oluphezulu kwaye ebandakanya iijometri ezintsonkothileyo azinakuthelekiswa nanto. Kwizibonelelo zethu zobuchwepheshe obuphezulu, sinikezela zombini umatshini kunye nokusebenza ngokubumba ngesandla kwiinkqubo zethu zokulahla isanti. Sivelisa iinxalenye kwimiqulu ephantsi ukuya phezulu kwaye sigalela i-castings ukusuka kwi-0.5 kg ukuya kwiitoni. Ukubunjwa kwethu kwesanti eluhlaza ukusuka kwi-0.5 kgs ukuya kwi-800 kgs