I-OEM yesiko lokuphosa iflenge yobhedu kunye namanye amacandelo obhedu otyalo-mali adlala indima ebalulekileyo njengokuthwala i-bushings, iigiya, ivalve kunye nemizimba yempompo, imibhobho yamanzi kunye nezinye.amashishini oomatshiniezidinga ukusebenza kokumelana nomhlwa kunye nokumelana nokunxiba.

Njengeyona nto isetyenziswa kakhulu kwi-alloy-based alloy, ubhedu lunokwenziwa lube ngamalungu okuphosa anzima kakhulu, okwenza ukuba alungele inkqubo yokuphosa imali. Ukuguquguquka rhoqo kweendleko kunokwenza ezi mathiriyeli zibe novakalelo kakhulu, zenze inkcitho ibe yindleko enkulu, ngakumbi xa kuqwalaselwa ukwenziwa komatshini we-CNC kunye / okanye ukudibanisa njengenkqubo yokuvelisa ukuvelisa imveliso yakho.iindawo eziphosiweyo. Nangona kunjalo, ubhedu olucocekileyo aluqhelekanga ukuphoswa. I-Casting brass ineempawu eziphezulu ze-mechanical kune-bronze, kodwa ixabiso liphantsi kunobhedu.

Ubhedu yi-alloy eyenziwe ngobhedu kunye ne-zinc. Ubhedu olwakhiwe ngobhedu kunye ne-zinc lubizwa ngokuba lubhedu oluqhelekileyo. Ukuba luhlobo lwe-alloys oluqulunqwe ngaphezu kwezinto ezimbini, kuthiwa lubhedu olukhethekileyo. I-Brass yi-alloy yobhedu ene-zinc njengeyona nto iphambili. Njengoko umxholo we-zinc ukhula, amandla kunye neplastiki ye-alloy yanda kakhulu, kodwa iimpawu zomatshini ziya kuncipha kakhulu emva kokudlula i-47%, ngoko umxholo we-zinc wobhedu ungaphantsi kwama-47%. Ukongeza kwi-zinc, ubhedu oluphosiweyo luhlala luqulethe izinto ezixubileyo ezifana ne-silicon, i-manganese, i-aluminium kunye nelothe.

Yintoni esiyiphosa ngeBrass kunye neBronzi

- • Umgangatho waseTshayina: H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2

- • Umgangatho wase-USA: C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100

- • Umgangatho waseYurophu: CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5

| Isinyithi esifumanekayo kunye nee-alloys zokuCasa ezahlukeneyo kunye neNkqubo yokuVelisa

| ||

| INKQUBO YOKWENZA | IZINTO | |

| Isanti yokuphosa | Ukuphosa kweSanti eluhlaza | Intsimbi ye-Grey Cast, i-Ductile Cast Iron, i-Iron eMalleable, iStainless Steel, i-Carbon Steel, i-alloy Steel, i-Aluminiyam ingxubevange, ubhedu, njl. |

| I-Resin efakwe kwiSanti yokuCasa | ||

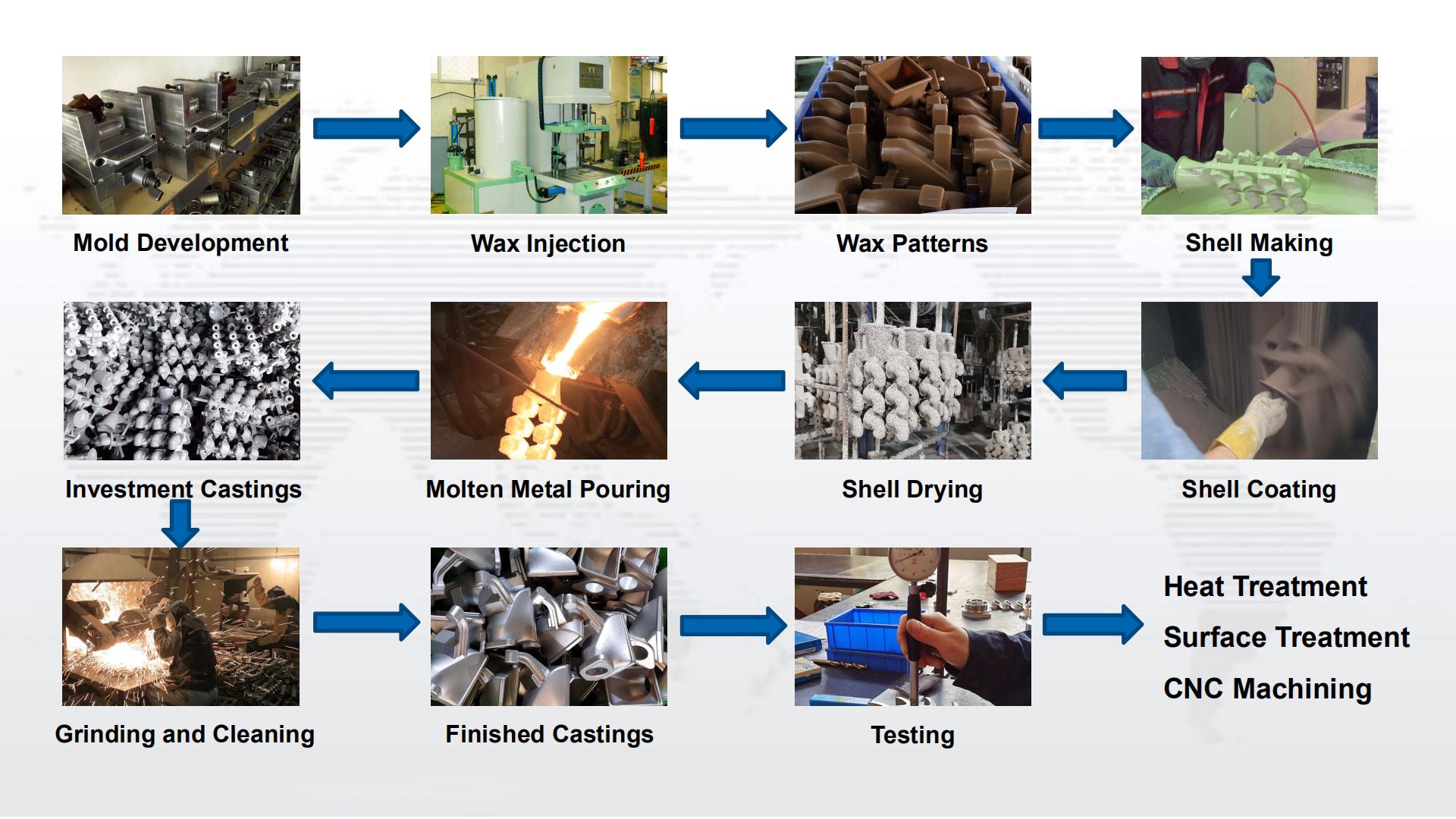

| Ukulahlwa koTyalo-mali (Ukulahlwa kweWax elahlekileyo) | Iglasi yamanzi Investment Casting | Intsimbi yeCarbon, intsimbi yengxubevange, intsimbi engatyiwa, iDuplex Steel, intsimbi yokuphosa, ubhedu, iAluminiyam kunye nezinye izinto |

| I-Silica Sol Investment Casting | ||

| Ukuphosa amagwebu alahlekileyo | Ductile Cast Iron / Grey Cast Intsimbi | |

| ASTM 60-40-18 / 65-45-12 / 80-55-06 / 100-70-03 | ||

| Carbon steel, Hi-Mn steel, Hi-Cr steel | ||

| I-Austempering Ductile Iron (ADI) | ||

| Intsimbi eNganyangekiyo kuBubushushu / Nxiba iSimbi esiNganyangekiyo | ||

| Ukusalwa kweVacuum (V Inkqubo yokuSasa) | I-Ductile iron GGG 40 ukuya kwi-GGG 80 / i-Iron eGrey | |

| ASTM 60-40-18 / 65-45-12 / 80-55-06 / 100-70-03 | ||

| Carbon steel, Hi-Mn steel, Hi-Cr steel | ||

| Intsimbi ye-austempering ductile | ||

| Intsimbi ekwaziyo ukumelana nobushushu / Nxiba intsimbi ekwaziyo ukumelana nobushushu / intsimbi engatyiwayo | ||

| Ukuqulunqa | Vula Forging | Intsimbi engatyiwa, iCarbon Steel, iAlloy Steel, ubhedu, iAluminiyam |

| Die Forging | ||

| Roll Forging | ||

| Die Casting | Uxinzelelo oluphezulu Die Casting | I-Aluminiyam, iZinc, iBrass |

| Uxinzelelo oluphantsi Die Casting | ||

| Uxinzelelo lweGravity Die Casting | ||

| Iinkonzo zoNyango loMphezulu | I-Powder Coating, i-Anodization, i-Electrophotesis, i-Chrome Plating, i-Painting, i-Sand blasting, i-Nickel Plating, i-Zinc Plating, i-Blacking, i-Polishing, i-Bluing, i-Geormet, i-Zintek, njl. | |

| Iinkonzo ze-CNC Precision Machining | Lathing, Milling, Turning, Honing, Drilling, Boring, Tapping, Wire Electrode Cutting, Grinding... etc. | |

| Ukuhlolwa kunye noLawulo loMgangatho | I-Spectrum Analyzer, i-CMM, i-Hardness Tester, i-Tensile Strength Tester, i-Yild Strentgh Testor, i-Seal Pressure Tester, i-Carbon Sulfur Analyzer, i-Metallurgical Microscopy, i-Press Force Tester ... njl. | |