I-2205 i-duplex insimbi engenasici i-duplex yensimbi engenasici eyenziwe nge-21% ye-chromium, i-2.5% ye-molybdenum kunye ne-4.5% ye-nickel-nitrogen alloy. I-ferrite kunye nezakhiwo ze-austenite akhawunti nganye malunga ne-50%. Inamandla aphezulu, ukuqina kwempembelelo elungileyo kunye nokuchasana kokutya kunye noxinzelelo lwasekhaya. Amandla emveliso ye2205 duplex steel stainless iphindwe kabini kune-austenitic stainless steel. Olu phawu lwenza abaqulunqi banciphise ubunzima xa beyila iimveliso, okwenza le ngxube ingabizi kakhulu kune-316 kunye ne-317L. Le ingxubevange ifaneleke ngokukodwa kuluhlu lobushushu -50°F/+600°F. Ukusetyenziswa ngaphaya kolu luhlu lweqondo lokushisa, le ngxube ingaqwalaselwa kwakhona, kodwa kukho imida, ngakumbi xa isetyenziswe kwizakhiwo ezidibeneyo.

Xa kuthelekiswa ne-316L kunye ne-317L i-austenitic steel stainless, i-2205 i-duplex yensimbi engenasici inokusebenza okuphezulu ekuchaseni ukubola kwemigodi kunye ne-crevice corrosion. Inokumelana ne-corrosion ephezulu. Xa kuthelekiswa ne-austenitic, yayo I-coefficient yokwandiswa kwe-thermal iphantsi kwaye i-thermal conductivity iphezulu. Xa kuthelekiswa ne-austenitic steel stainless, i-duplex stainless steel 2205 alloy inamandla aphindwe kabini. Xa kuthelekiswa ne-316L kunye ne-317L, umyili unokunciphisa ubunzima bayo. Ingxubevange 2205 ifaneleke ngokukodwa kuluhlu lobushushu -50 ° F / + 600 ° F. Ngaphantsi kwezithintelo eziqinileyo (ngokukodwa kwizakhiwo ezidibeneyo), zingasetyenziselwa kumaqondo okushisa aphantsi.

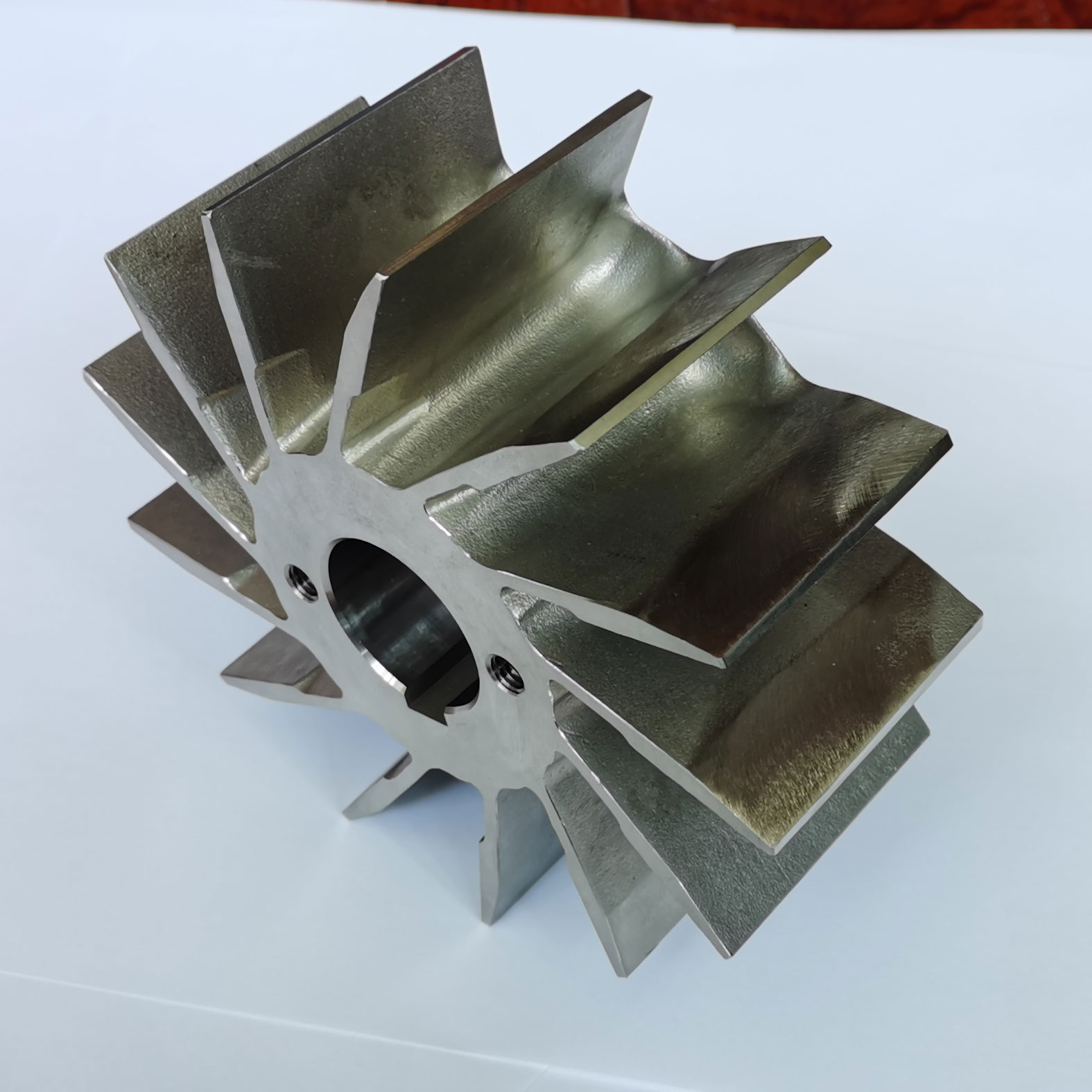

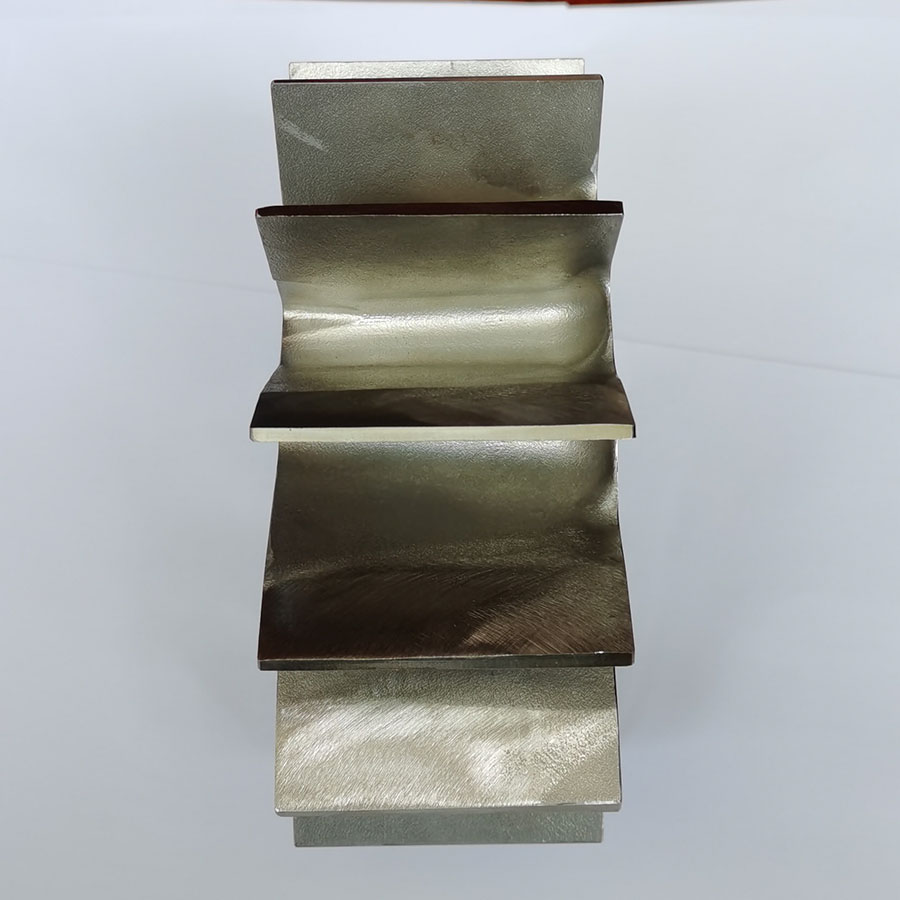

Duplex steel stainless castingkuthetha ukubunjwa okwenziwe ngentsimbi ephindwe kabini. I-Duplex Stainless Steel (i-DSS) ibhekisela kwinsimbi engenasici nge-ferrite kunye ne-austenite nganye i-accounting malunga ne-50%. Ngokuqhelekileyo, umxholo wezigaba ezingaphantsi kufuneka ubuncinane ube ngama-30%. Kwimeko yomxholo we-C ophantsi, umxholo we-Cr yi-18% ukuya kwi-28%, kwaye umxholo we-Ni yi-3% ukuya kwi-10%. Ezinye iintsimbi ezingenazintsimbi eziphindwe kabini zikwanazo izinto zokuhlanganisa ezifana neMo, Cu, Nb, Ti, kunye neN.

I-DSS ineempawu ze-austenitic kunye ne-ferritic stainless steel. Xa kuthelekiswa ne-ferrite, ineplastiki ephezulu kunye ne-ductility, akukho brittleness yegumbi, kwaye iphucule kakhulu ukuxhathisa kwe-intergranular corrosion kunye nokusebenza kwe-welding, ngelixa igcina i-brittleness, i-thermal conductivity ephezulu, kunye ne-superplasticity njenge-ferrite stainless steel. Xa kuthelekiswa ne-austenitic steel stainless, i-DSS inamandla aphezulu kwaye iphucule kakhulu ukuchasana ne-intergranular corrosion kunye ne-chloride stress corrosion. I-Duplex steel stainless steel ine-pitting corrosion resistance encomekayo kwaye ikwayintsimbi egcina i-nickel engatyiwa.

Kwimveliso yokuphosa, ininzi yensimbi engenasici igqitywe ngoutyalo mali. Umphezulu wensimbi engenasici eveliswa yi-investment casting ilula kwaye ukuchaneka kwe-dimensional kulula ukulawula. Kakade ke, iindleko zeutyalo-mali lokugalela iinxalenye zentsimbi engenasiciiphezulu kakhulu xa kuthelekiswa nezinye iinkqubo kunye nemathiriyeli.

▶ IzakhonoInvestment Casting Foundry

• Ubungakanani obukhulu: 1,000 mm × 800 mm × 500 mm

• Ubunzima Uluhlu: 0.5 kg - 100 kg

• Umthamo woNyaka: iitoni ezingama-2,000

• IiMathiriyeli zeBond kwiSakhiwo seShell: ISilica Sol, iglasi yamanzi kunye nemixube yazo.

• Unyamezelo: Ngesicelo.

▶ Eyona Nkqubo yeMveliso yoTyalo-mali

• Yenza ipateni yewax okanye ikopi

• Hlikihla ipateni yewax

• Tyala ipateni yewax

• Susa ipateni yewax ngokuyitshisa (ngaphakathi kwiziko okanye emanzini ashushu) ukwenza isikhunta.

• Nyanzelisa ukugalela isinyithi esinyibilikisiweyo kumngundo

• Ukupholisa nokuqinisa

• Susa i-sprue kwi-castings

• Gqibezela kwaye upolishe utyalo-mali olugqityiweyo