Isiko lomdlaloduplex stainless steel stainless imveliso yokugalelaevela eTshayina ephosa isiseko esinomatshini, unyango lobushushu, kunye neenkonzo zonyango zomphezulu.

RMC castiindawo zentsimbi ezichanekileyoezihlala zihlangabezana okanye zigqithise oko kulindelwe ngabathengi. Ukuphosa utyalo-mali olulahlekileyo kusivumela ukuba sivelise iinxalenye zentsimbi ezincinci njengeegrem zamashumi kwaye zinkulu njengeekhilogram zamashumi, kuluhlu olubanzi lweealloyi ezine-ferrous kunye ne-non-ferrous kunye nokuchaneka okukhethekileyo kwe-dimensional.

Inkqubo yokuphosa i-wax elahlekileyo ivelisa iindawo zentsimbi ezichanekileyo ezikufutshane-netha ezihlala zifuna ukucwangciswa okuncinci okanye akukho kwangezelelweyo. Ukugqitywa kwesiphumo nako kungcono kakhulu kunoko kufezekiswa ngezinye iinkqubo. Amandla kunye nokuqina kwamalungu okujula azenza alungele usetyenziso oluphezulu lokuxhathisa olufuna izigidi zemijikelo.

I-Duplex Stainless Steel (i-DSS) ibhekisela kwinsimbi engenasici nge-ferrite kunye ne-austenite nganye i-accounting malunga ne-50%. Ngokuqhelekileyo, umxholo wezigaba ezingaphantsi kufuneka ubuncinane ube ngama-30%. Kwimeko yomxholo we-C ophantsi, umxholo we-Cr yi-18% ukuya kwi-28%, kwaye umxholo we-Ni yi-3% ukuya kwi-10%. Ezinye iintsimbi ezingenazintsimbi eziphindwe kabini zikwanazo izinto zokuhlanganisa ezifana neMo, Cu, Nb, Ti, kunye neN.

Ibakala elifumanekayo duplex steel stainless kwi RMC Casting Foundry: 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770, A 890 1C, A 890 1A, A 890, 08 A9A 8 A9A 9A 890, 8 A9A 9A9, 995 1B, A 995 4A, A 995 5A, 2205, 2507, 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N

I-DSS ineempawu ze-austenitic kunye ne-ferritic stainless steel. Xa kuthelekiswa ne-ferrite, ineplastiki ephezulu kunye ne-ductility, akukho brittleness yegumbi, kwaye iphucule kakhulu ukuxhathisa kwe-intergranular corrosion kunye nokusebenza kwe-welding, ngelixa igcina i-brittleness, i-thermal conductivity ephezulu, kunye ne-superplasticity njenge-ferrite stainless steel. Xa kuthelekiswa ne-austenitic steel stainless, i-DSS inamandla aphezulu kwaye iphucule kakhulu ukuchasana ne-intergranular corrosion kunye ne-chloride stress corrosion. I-Duplex steel stainless steel ine-pitting corrosion resistance encomekayo kwaye ikwayintsimbi egcina i-nickel engatyiwa.

| IBanga eliLinganayo leNtsimbi eNgatyiwayo | |||||||

| AMAQELA | AISI | I-W-stoff | I-DIN | BS | SS | UNE / IHA | I-UNI |

| Intsimbi yentsimbi yeMartensitic kunye neFerritic | 420 C | 1,4034 | X43Cr16 | ||||

| 440 B/1 | 1,4112 | X90 Cr Mo V18 | |||||

| - | 1.2083 | X42 Kr 13 | - | 2314 | F.5263 | - | |

| 403 | 1.4000 | X6Cr13 | 403 S 17 | 2301 | F.3110 | X6Cr13 | |

| (410S) | 1.4001 | X7 Kr 14 | (403 S17) | 2301 | F.3110 | X6Cr13 | |

| 405 | 1.4002 | X6 CrAl 13 | 405 S 17 | - | F.3111 | X6 CrAl 13 | |

| 416 | 1.4005 | X12 CrS 13 | 416 S 21 | 2380 | F.3411 | X12CrS13 | |

| 410 | 1.4006 | X 10 Kr 13 | 410 S21 | 2302 | F.3401 | X12Cr13 | |

| 430 | 1.4016 | X6 Kr 17 | 430 S 17 | 2320 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | X20 Cr 13 | 420 S 37 | 2303 | F.3402 | X20Cr13 | |

| 420F | 1.4028 | X30 Cr 13 | 420 S 45 | (2304) | F.3403 | X30Cr13 | |

| (420) | 1.4031 | X39Cr13 | 420 S 45 | (2304) | F.3404 | - | |

| 431 | 1.4057 | X20 CrNi 17 2 | 431 S 29 | 2321 | F.3427 | X16CrNi16 | |

| 430F | 1.4104 | X12 CrMoS 17 | - | 2383 | F.3117 | X10CrS17 | |

| 434 | 1.4113 | X6 CrMo 17 | 434 S17 | 2325 | - | X8CrMo17 | |

| 430Ti | 1.4510 | X6 CrTi 17 | - | - | - | X6CrTi17 | |

| 409 | 1.4512 | X5 CrTi 12 | 409 S 17 | - | - | X6CrTi12 | |

| Intsimbi yeAustenitic engatyiwa | 304 | 1.4301 | X5 CrNi 18 9 | 304 S 15 | 2332 | F.3551 | X5CrNi18 10 |

| 305 | 1.4303 | X5 CrNi 18 12 | 305 S 19 | - | - | X8CrNi19 10 | |

| 303 | 1.4305 | X12 CrNiS 18 8 | 303 S 21 | 2346 | F.3508 | X10CrNiS 18 09 | |

| 304L | 1.4306 | X2 CrNiS 18 9 | 304 S 12 | 2352 | F.3503 | X2CrNi18 11 | |

| 301 | 1.4310 | X12 CrNi 17 7 | - | 2331 | F.3517 | X12CrNi17 07 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2332 | F.3551 | X5CrNi18 10 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2333 | F.3551 | X5CrNi18 10 | |

| 304LN | 1.4311 | X2 CrNiN 18 10 | 304 S62 | 2371 | - | - | |

| 316 | 1.4401 | X5 CrNiMo 18 10 | 316 S16 | 2347 | F.3543 | X5CrNiMo17 12 | |

| 316L | 1.4404 | - | 316 S 12/13/14/22/24 | 2348 | X2CrNiMo17 12 | ||

| 316LN | 1.4429 | X2 CrNiMoN 18 13 | - | 2375 | - | - | |

| 316L | 1.4435 | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24 | 2353 | - | X2CrNiMo17 12 | |

| 316 | 1.4436 | - | 316 S 33 | 2343 | - | X8CrNiMo 17 13 | |

| 317L | 1.4438 | X2 CrNiMo 18 16 | 317 S 12 | 2367 | - | X2CrNiMo18 16 | |

| 329 | 1.4460 | X3 CrNiMoN 27 5 2 | - | 2324 | F.3309 | - | |

| 321 | 1.4541 | X10 CrNiTi 18 9 | 321 S 12 | 2337 | F.3553 | X6CrNiTi18 11 | |

| 347 | 1.4550 | X10 CrNiNb 18 9 | 347 S 17 | 2338 | F.3552 | X6CrNiNb18 11 | |

| 316Ti | 1.4571 | X10 CrNiMoTi 18 10 | 320 S 17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 | X15 CrNiSi 20 12 | 309 S 24 | - | - | X16 CrNi 24 14 | |

| 330 | 1.4864 | X12 NiCrSi 36 16 | - | - | - | - | |

| Duplex Steel engatyiwa | S32750 | 1.4410 | X 2 CrNiMoN 25 7 4 | - | 2328 | - | - |

| S31500 | 1.4417 | X 2 CrNiMoSi 19 5 | - | 2376 | - | - | |

| S31803 | 1.4462 | X 2 CrNiMoN 22 5 3 | - | 2377 | - | - | |

| S32760 | 1.4501 | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 | X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

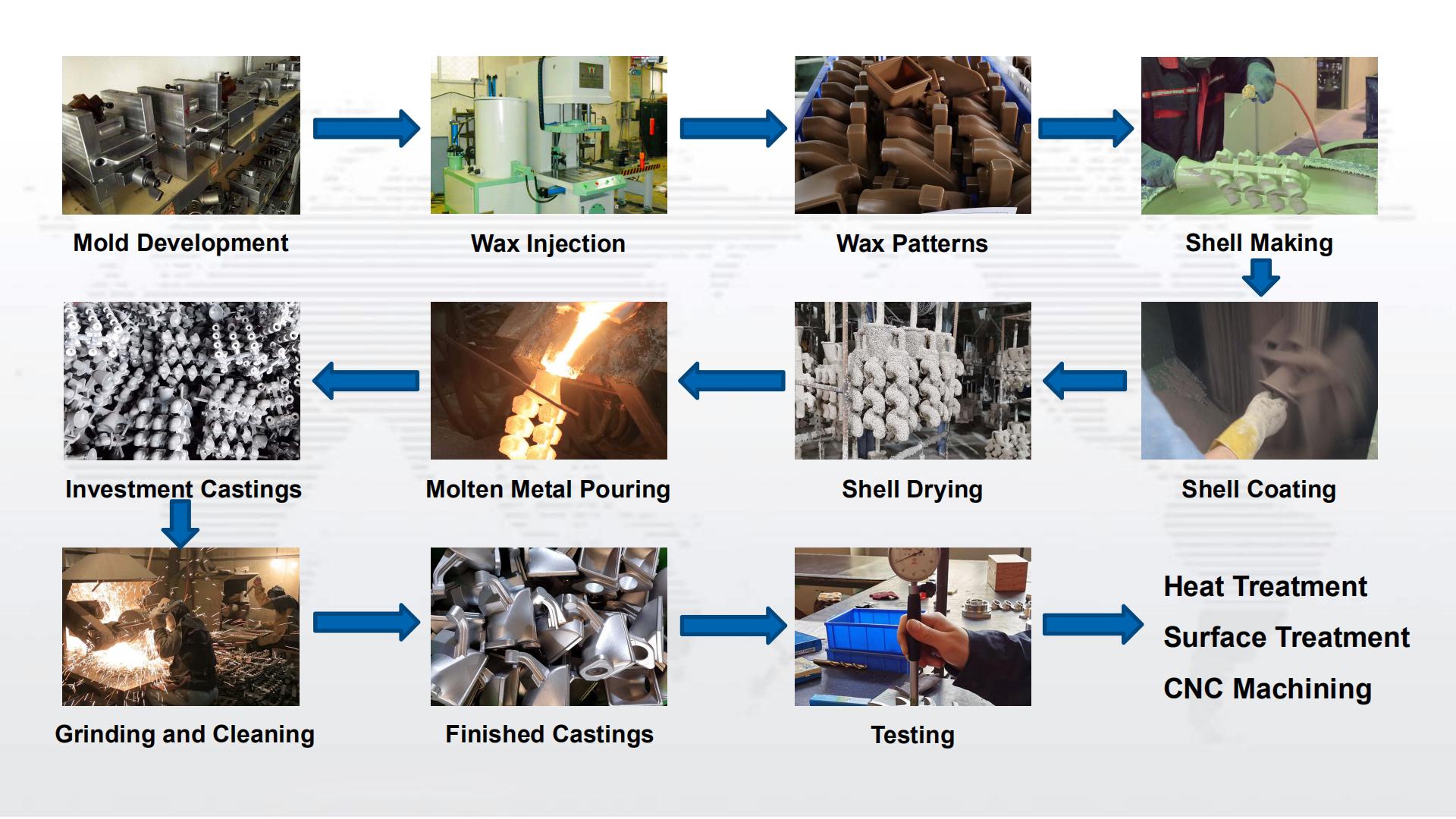

▶ Iintsimbi zentsimbi kunye neentsimbi ezingezizo intsimbiUtyalo-mali lokuCasa, Inkqubo yokuphosa iWax elahlekileyo:

• Intsimbi engwevu: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

• I-Ductile Iron okanye i-Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

• Intsimbi yeCarbon: AISI 1020 - AISI 1060, C30, C40, C45.

• I-Steel Alloys: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo...etc ngesicelo.

• I-Stainless Steel: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 kunye nezinye ibakala lensimbi engenasici.

• Ubhedu, ubhedu olubomvu, uBronze okanye ezinye iintsimbi ezisekelwe kwi-Copper: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

• Ezinye iiMathiriyeli ngokweemfuno zakho ezizodwa okanye ngokwe-ASTM, SAE, AISI, ACI, DIN, EN, ISO, kunye nemigangatho yeGB

▶ IzakhonoInvestment Casting Foundry

• Ubungakanani obukhulu: 1,000 mm × 800 mm × 500 mm

• Ubunzima Uluhlu: 0.5 kg - 100 kg

• Umthamo woNyaka: iitoni ezingama-2,000

• IiMathiriyeli zeBond kwiSakhiwo seShell: ISilica Sol, iglasi yamanzi kunye nemixube yazo.

| Iinkonzo | Inkcazo |

| Iinkonzo zoNyango loMphezulu | I-Powder Coating, i-Anodization, i-Electrophotesis, i-Chrome Plating, i-Painting, i-Sand blasting, i-Nickel Plating, i-Zinc Plating, i-Blacking, i-Polishing, i-Bluing, i-Geormet, i-Zintek, njl. |

| Iinkonzo ze-CNC Precision Machining | Lathing, Milling, Turning, Honing, Drilling, Boring, Tapping, Wire Electrode Cutting, Grinding... etc. |

| Ukuhlolwa kunye noLawulo loMgangatho | I-Spectrum Analyzer, i-CMM, i-Hardness Tester, i-Tensile Strength Tester, i-Yild Strentgh Testor, i-Seal Pressure Tester, i-Carbon Sulfur Analyzer, i-Metallurgical Microscopy, i-Press Force Tester ... njl. |