Iimveliso zentsimbi ezingwevu ngeinkqubo yokuphosa isantikunye noomatshini beCNC.

Intsimbi engwevu ithiywe ngombala ongwevu wokuqhekeka kwayo. Intsimbi yentsimbi engwevu isetyenziselwa izindlu apho ukuqina kwecandelo kubaluleke kakhulu kunamandla okuqina, njengeebhloko ze-cylinder injini yokutsha yangaphakathi, izindlu zempompo, imizimba yevalvu, iibhokisi zombane, iintsimbi zokubala kunye neentsimbi zokuhombisa. Intsimbi engwevu yentsimbi ehambisa ukushisa kunye nomthamo wentloko ethile idla ngokusetyenziswa ukwenza intsimbi yokupheka yentsimbi kunye nedisc brake rotors.

Ukubunjwa kweekhemikhali eziqhelekileyo ukufumana i-microstructure ye-graphic yi-2.5 ukuya kwi-4.0% yekhabhoni kunye ne-1 ukuya kwi-3% ye-silicon ngesisindo. Igraphite inokuthatha i-6 ukuya kwi-10% yomthamo wentsimbi engwevu. I-silicon ibalulekile ukwenza isinyithi esimpunga ngokuchasene nentsimbi emhlophe, kuba i-silicon yinto yokuzinzisa i-graphite kwi-iron cast, oku kuthetha ukuba inceda i-alloy ivelise i-graphite endaweni ye-carbides yensimbi; kwi-3% ye-silicon phantse akukho khabhoni ebanjwe kwimichiza edibeneyo kunye nentsimbi.

Igraphite ithatha imilo yeflake ene-dimensional ezintathu. Kwimilinganiselo emibini, njengoko ubuso obukhazimlisiweyo buza kubonakala phantsi kwe-microscope, iiflake zegraphite zibonakala njengemigca emihle. Iingcebiso zeeflakes zisebenza njengamanotshi asele ekhona; ngoko ke, ibhityile. Ubukho be graphite flakes benza i-Grey Iron ikwazi ukucatshukiswa lula njengoko zithanda ukuqhekeka ngokulula kwiiflake zegraphite. Intsimbi engwevu ikwanesakhono sokumanzisa kakuhle kakhulu kwaye yiyo loo nto isetyenziswa kakhulu njengesiseko sokunyuswa kwezixhobo zoomatshini.

IiPropati zeMechanical zentsimbi eziGrey Cast | |||||||

| Into ngokwe-DIN EN 1561 | Umlinganiselo | Iyunithi | EN-GJL-150 | EN-GJL-200 | EN-GJL-250 | EN-GJL-300 | EN-GJL-350 |

| EN-JL 1020 | EN-JL 1030 | EN-JL 1040 | EN-JL 1050 | EN-JL 1060 | |||

| Tensile strength | Rm | IMPA | 150-250 | 200-300 | 250-350 | 300-400 | 350-450 |

| 0.1% Amandla eSivuno | Rp0,1 | IMPA | 98-165 | 130-195 | 165-228 | 195-260 | 228-285 |

| Amandla okwandisa | A | % | 0,3 – 0,8 | 0,3 – 0,8 | 0,3 – 0,8 | 0,3 – 0,8 | 0,3 – 0,8 |

| Amandla acinezelayo | σdB | MPa | 600 | 720 | 840 | 960 | 1080 |

| 0,1% Amandla oxinzelelo | σd0,1 | MPa | 195 | 260 | 325 | 390 | 455 |

| Amandla e-Flexural | σbB | MPa | 250 | 290 | 340 | 390 | 490 |

| Schuifspanning | σaB | MPa | 170 | 230 | 290 | 345 | 400 |

| Phungula ucinzelelo | TtB | MPa | 170 | 230 | 290 | 345 | 400 |

| Iimodyuli zokunwebeka | E | GPA | 78 – 103 | 88 – 113 | 103 – 118 | 108 – 137 | 123 – 143 |

| Inombolo yePoisson | v | - | 0,26 | 0,26 | 0,26 | 0,26 | 0,26 |

| Ukuqina kweBrinell | HB | 160-190 | 180 – 220 | 190 – 230 | 200 - 240 | 210 – 250 | |

| I-Ductility | σbW | MPa | 70 | 90 | 120 | 140 | 145 |

| Uxinzelelo kunye nokutshintsha koxinzelelo | σzdW | MPa | 40 | 50 | 60 | 75 | 85 |

| Ukuqhawula Amandla | Klc | N/mm3/2 | 320 | 400 | 480 | 560 | 650 |

| Ukuxinana | g/cm3 | 7,10 | 7,15 | 7,20 | 7,25 | 7,30 | |

Ukugalelwa kwesanti kusebenzisa isanti eluhlaza (isanti emanzi) okanye isanti eyomileyo ukwenza iinkqubo zokubumba. Ukugalelwa kwesanti eluhlaza yinkqubo yakudala esetyenziswa kwimbali. Xa usenza isikhunta, iipatheni ezenziwe ngomthi okanye isinyithi kufuneka ziveliswe ukuze zenze umgodi ongenanto. Isinyithi esinyibilikisiweyo sigalela emngxunyeni ukwenza icastings emva kokupholisa kunye nokuqina. Ukwenziwa kwesanti kubiza ngaphantsi kunezinye iinkqubo zokuphosa zombini kuphuhliso lokungunda kunye neyunithi yokuphosa inxalenye. Ukuphosa isanti, kusoloko kuthetha ukuphosa kwesanti eluhlaza (ukuba akukho nkcazo ekhethekileyo). Nangona kunjalo, kule mihla, ezinye iinkqubo zokuphosa nazo zisebenzisa isanti ukwenza umngundo. Banamagama abo, njengayeiqokobhe ngundo ukuphosa, i-furan resin egqunywe isanti egayiweyo (akukho ntlobo yokubhaka),ukuphosa amagwebukunye ne-vacuum casting.

Isanti yokuphosa izakhono kwi-RMC Foundry | ||

| Inkcazo | Ukubunjwa ngesandla | Ukubunjwa ngoomatshini abazenzekelayo |

| Ubungakanani obukhulu bokuCasa | 1,500 mm × 1000 mm × 500 mm | 1,000 mm × 800 mm × 500 mm |

| Uluhlu lobunzima bokuphosa | 0.5 kg - 1,000 kg | 0.5 kg - 500 kg |

| Amandla oNyaka | Iitoni ezingama-5,000 - iitoni ezingama-6,000 | 8,000 iitoni - 10,000 iitoni |

| Ukuphosa Ukunyamezela | Ngesicelo okanye emgangathweni (ISO8062-2013 okanye GB/T 6414-1999) | |

| Izinto zokubumba | Isanti eluhlaza, Isanti egqunywe yiResin | |

| Ukuphosa isinyithi kunye ne-alloys | I-iron engwevu, i-Ductile Iron, i-Cast Steel, i-Stainless Steel, i-Al Alloys, i-Brass, iBronze ... njl. | |

Izinto eziluncedo zokuphosa isanti:

- ✔ Iindleko eziphantsi ngenxa yexabiso eliphantsi kunye nezixhobo zokubumba ezinokusetyenziswa kwakhona kunye nezixhobo ezilula zokuvelisa.

- ✔ Uluhlu olubanzi lobunzima beyunithi ukusuka kwi-0.10 kg ukuya kwi-500 kgs okanye nangaphezulu.

- ✔ Ulwakhiwo olwahlukeneyo ukusuka kuhlobo olulula ukuya kuhlobo oluntsonkothileyo.

- ✔ Ifanelekile kwiimfuno zemveliso zobuninzi obahlukeneyo.

Unyamezelo olwenziwa kwiSand Castings:

Ukunyamezela ukuphosa kwahlulwe kwi-Dimensional Casting Tolerances (DCT) kunye neGeometrical Casting Tolerances (GCT). Isebe lethu lingathanda ukuthetha nawe ukuba unesicelo esikhethekileyo malunga nonyamezelo olufunekayo. Apha koku kulandelayo kukho ibakala lokunyamezelana ngokubanzi esinokufikelela kulo ngokugatywa kwesanti eluhlaza, ukubunjwa kweqokobhe kunye nokugaywa kwesanti ye-furan resin:

- ✔ IBanga le-DCT nge-Green Sand Casting: CTG10 ~ CTG13

- ✔ IBanga leDCT ngeShell Mold Casting okanye iFuran Resin Sand Casting: CTG8 ~ CTG12

- ✔ IBanga le-GCT ngeSanti yeGreen Casting: CTG6 ~ CTG8

- ✔ IBanga le-GCT ngeShell Mold Casting okanye iFuran Resin Sand Casting: CTG4 ~ CTG7

IBanga leMetal kunye ne-Alloys kwiiNkqubo zeSanti yokuCasa | |

| Isinyithi kunye neeAlloys | IBanga elidumileyo |

| Grey Cast Intsimbi | GG10~GG40; GJL-100 ~ GJL-350; |

| I-Ductile (Nodualar) Intsimbi yokuphosa | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| I-Austempered Ductile Iron (ADI) | EN-GJS-800-8, EN-GJS-1000-5, EN-GJS-1200-2 |

| Intsimbi yeCarbon | C20, C25, C30, C45 |

| Intsimbi yentsimbi | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Yenziwe ngentsimbi eshayinayo | I-Ferritic Stainless Steel, i-Martensitic Stainless Steel, i-Austenitic Stainless Steel, i-Precipitation Hardinless Steel, i-Duplex Stainless Steel |

| Iingxube zeAluminiyam | ASTM A356, ASTM A413, ASTM A360 |

| Ubhedu / i-Alloys esekwe kwiCopper | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Umgangatho: ASTM, SAE, AISI, GOST, DIN, EN, ISO, kunye ne-GB | |

-

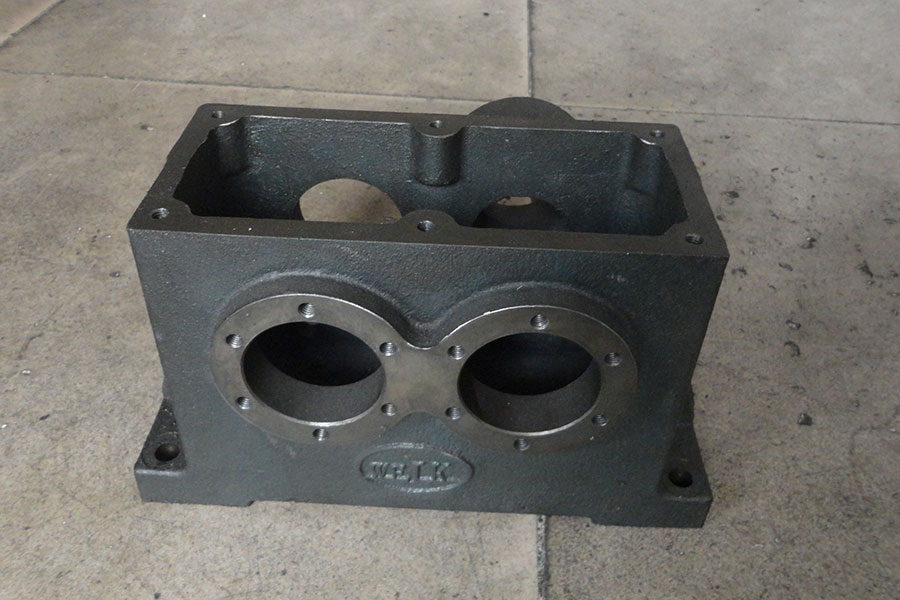

Imveliso ye-Grey Cast ye-Iron Sand

-

Grey Cast Iron Shell Casting Product

-

OEM Gray Cast Iron Casting

-

Ingxubevange Steel Resin Coated Sanding Casting Crankshaft

-

Ingxubevange Steel Sand Castings

-

Izahlulo zelori ye-Alloy Steel ngeSand Casting kunye ne-CNC...

-

Inkampani yeCarbon Steel Casting Sanding

-

Cast Steel Sand Casting

-

I-Aluminiyam ye-Alloy yeSand Casting