Investment Casting Foundry

Ukuphosa utyalo-mali, okwakwaziwa njengokuphoswa kwewax elahlekileyo okanye ukuphosa ngokuchanekileyo, yinkqubo esele isenziwa kangangamawaka eminyaka, kunye nenkqubo elahlekileyo yewax yenye yeendlela zakudala ezaziwayo zokubumba isinyithi.

Ngenxa yesakhiwo esiyinkimbinkimbi kumlinganiselo kunye nejometri, ukuchithwa kotyalo-mali kuveliswa ukufikelela kwimilo yomnatha okanye kufuphi nesakhiwo somnatha, ukunciphisa imfuno yeenkqubo zesibini ezifana ne-lathing, ukujika okanye ezinye izinto.CNC machininginkqubo.

Ukwenziwa kotyalo-mali yinkqubo yokwenziwa kwemveliso enokulandelelwa emva kwiminyaka engama-5,000 eyadlulayo. Ukususela ngoko, xa i-bewax yenza ipateni, ukuya kwii-wax zeteknoloji eziphezulu zanamhlanje, izinto eziphikisayo kunye ne-alloys ezikhethekileyo, ukuphosa kwe-wax elahlekileyo kuqinisekisa ukuba amacandelo aphezulu avelisiweyo kunye neenzuzo zokuchaneka, ukuphindaphinda kunye nokunyaniseka.

Ukwenziwa kotyalo-mali kufumaneka kwigama layo kwinto yokuba ipateni ityalwe, okanye irhangqwe, ngezinto ezichasayo. Iipateni ze-wax zifuna ukunakekelwa okugqithisileyo kuba azinamandla ngokwaneleyo ukuba zimelane nemikhosi edibana nayo ngexesha lokubumba.

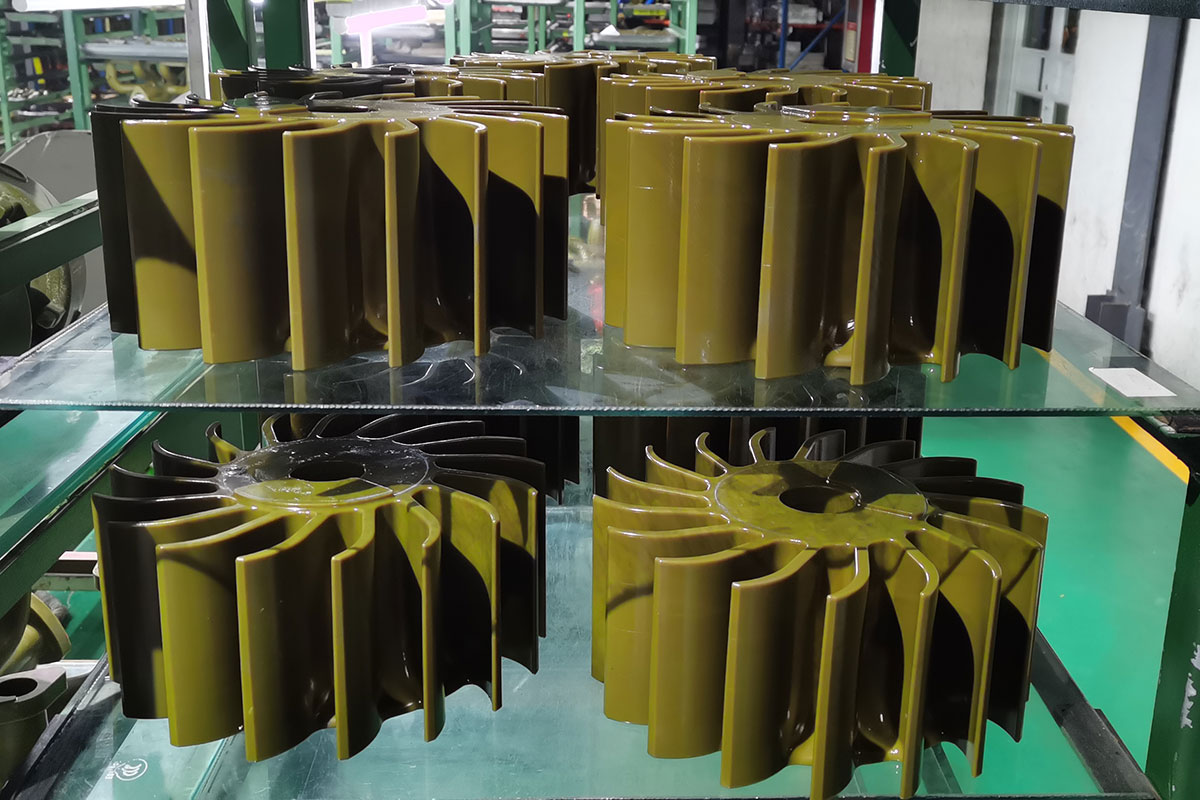

Investment Casting Foundry

Yintoni esinokuyifeza ngokulahlwa kweWax Investment Casting

Ilahleko yotyalo-mali lwe-wax ene-silica sol njengesixhobo sokubopha inokufikelela kwibakala lokunyamezela idimensional CT4 ~ CT7 ngokwe-ISO 8062. Izixhobo zethu ezilungelelaniswe ngokupheleleyo kunye nolawulo lwenkqubo yokuzenzekela zivumela ukunyamezela okungaguquguqukiyo nokuphindaphindwayo ngokusondeleyo njenge-± 0.1 mm. Iiindawo zokugalela umthwebeba ezilahlekileyonazo zinokuveliswa kuluhlu olubanzi lwesayizi, zisenokuba ncinane kangange-10 mm ubude x 10 mm ububanzi x 10 mm ukuphakama kwaye zinobunzima obungange-0.01 kg, okanye zibe nkulu kangange-1000 mm ubude kwaye zinobunzima obungange-200 kg. .

I-RMC lishishini elikhokela umenzi wotyalo-mali olukumgangatho ophezulu ozinikele ekunikezeni umgangatho obalaseleyo, ixabiso eliphezulu kunye namava akhethekileyo kubathengi. I-RMC inamava, ubuchule bobugcisa kunye neenkqubo zoqinisekiso lomgangatho wokuzisa ngokuthe rhoqo nangokuthembekileyo uluhlu olubanzi lokusaswa nokuqhubekeka.

- • Ubungakanani obukhulu bokuCasa: 1,000 mm × 800 mm × 800 mm

- • Uluhlu lobunzima beCast: 0.5 kg - 200 kg

- • Umthamo woNyaka:Iitoni ezingama-3,000

- • IiMathiriyeli zeBond kwiSakhiwo seShell:I-Silica Sol, iglasi yamanzi okanye imixube yabo.

- • Unyamezelo lokuphosa:I-CT4 ~ CT7 ngokwe-ISO 8062 okanye ngeSicelo.

Ukwenziwa kweShell Ngexesha Lokusasazwa koTyalo-mali

Zeziphi izinyithi kunye ne-alloys esinokugalela ngoTyalo-mali lokuCasa

Iisiseko sotyalo-malie-RMC iyakwazi ukuhlangabezana neentlobo ngeentlobo zezinto ze-alloys kunye neenkcukacha ngokwe-ASTM, SAE, AISI, ACI, DIN, GOST, EN, ISO, kunye nemigangatho ye-GB. Sine-alloys ezingaphezu kwe-100 ezahlukeneyo ze-ferrous kunye ne-non-ferrous esijula ngazo iinxalenye sisebenzisa ubume boyilo oluntsonkothileyo.

- • I-ayini ye-Grey Cast:HT150, HT200, HT250, HT300, HT350; EN-GJL-100, EN-GJL-150, EN-GJL-200, EN-GJL-250, EN-GJL-300, EN-GJL-350; GG10, GG15, GG20, GG25, GG30, GG40; I-ASTM A48 iGrey Iron Grades Class 20, Class 25, Class 30, Class 35, Class 40, Class 45, Class 50, Class 55, Class 60.

- • I-Ayini yeDuctile Cast (i-Nodular iron):China GB QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2; GGG40, GGG45, GGG50, GGG60, GGG70, GGG80; EN-GJS-400-18, EN-GJS-400-15, EN-GJS-450-10, EN-GJS-500-7, EN-GJS-600-3, EN-GJS-700-2, EN- GJS-800-2; ASTM A536 Ductile Iron Grades 60-40-18, 65-45-12, 70-50-05, 80-60-03, 100-70-03, 120-90-02.

- •Intsimbi yeCarbon:I-AISI 1020 ~ AISI 1060, C30, C40, C45.

- •Intsimbi yentsimbi:ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo, njl.

- •Yenziwe ngentsimbi eshayinayo:AISI 304, AISI 304L, AISI 316, AISI 316L,I-AISI 347, AISI 430, 1.4401, 1.4404, 1.4408, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571, CF3, CF3M, CF8, CF8M... njl.

- •I-Duplex Stainless Steel (DSS)kwayeUkuqina Kwemvula (PH) Intsimbi Engenasici

- • I-Brass, iBronzi kunye nezinye ii-Alloys eziseCopper

- •I-Nickel Based Alloy (Inconel 625, i-Inconel 713, i-Inconel 718 njl njl), i-Cobalt Based Alloys

- • Intsimbi enganyangekiyo ekutyeni, intsimbi ekwaziyo ukumelana namanzi olwandle, intsimbi yobushushu obuphezulu, intsimbi eqinileyo eqinileyo, iDuplex iStainless Steel.

- • Ingxubevange yeAluminiyam A356, A360

- • Ezinye ii-alloys njengesicelo okanye ngokwe-ASTM, SAE, AISI, GOST, DIN, EN, ISO, kunye ne-GB.

Stainless Steel Investment Casting

Investment Casting Mold

Al Mold for Lost Wax Casting

Metal Mold for Investment Casting

Ukungunda kweAluminiyam yeAluminiyam eGqibe ngokupheleleyo yokuCasa ngokuNcokisekileyo

Amanyathelo oLost Wax Investment Casting

Ukwenziwa kotyalo-mali yinkqubo enamanyathelo amaninzi evelisa ubume obusondeleyoiindawo zokuphosa ezichanekileyo. Inkqubo iqala nge-wax efakwe kwi-die ukwenza ipateni yemveliso egqityiweyo. Iipateni ke zincanyathiselwe kwimivalo ye-wax yembaleki ukwenza iqela.

Ngethuba lenkqubo yokutshala imali, umatshini okhethekileyo udibanisa i-cluster ngokuphindaphindiweyo kwi-slurry ukuphuhlisa igobolondo ye-ceramic, kwaye emva koko i-wax isuswe kwi-autoclave ye-steam. Emva kokuba i-wax isusiwe, iqokobhe le-ceramic liyagxothwa kwaye lizaliswe ngesinyithi esityhidiweyo ukwenza inxalenye. Enye inzuzo yokuphosa utyalo-mali kukuba i-wax ingaphinda isetyenziswe.

Ukuphosa utyalo-mali (Inkqubo yokuphosa iwax elahlekileyo) kufuna isinyithi (esidla ngokuba yi-aluminiyam), i-wax, i-ceramic slurry, i-furnace, isinyithi esityhidiweyo, kunye nabanye oomatshini abafunekayo kwinaliti ye-wax, ukuqhushumba kwesanti, ukudilika kokungcangcazela, ukusika, kunye nokusila. Inkqubo yotyalo-mali ibandakanya ikakhulu la manyathelo alandelayo:

1- Metal Die Ukwenza

Ngokusekelwe kwimizobo kunye neemfuno zecandelo elifunwayo, isinyithi sokufa okanye isikhunta, ngokuqhelekileyo kwi-aluminium, siya kuyilwa kwaye iveliswe. Umgodi uya kwenza ubungakanani obufanayo kunye nesakhiwo senxalenye efunwayo.

2- Isitofu seWax

Ekwabizwa ngokuba kukwenziwa kwepateni, Iipateni zokuphosa umthwebeba ezilahlekileyo zenziwe ngokutofa umthwebeba otyhidiweyo kwintsimbi efa ngaphezulu.

3- INdibano enodaka

Iipateni ze-wax ke zincanyathiselwe kwisixokelelwano sokungena, esikholisa ukuba yisethi yamajelo apho isinyithi esinyibilikisiweyo siphumela kumgodi wokungunda. Emva koko, isakhiwo esifana nomthi senziwe, esifanelekileyo kwimveliso yobuninzi.

4- Isakhiwo seShell

Utyalo-mali olufakwa kwiqokobhe leqokobhe langaphandle lwakhiwe ngokucwiliswa kwibhafu yeceramic emva koko igqunywe ngesanti amaxesha amaninzi.

5- Ukukhupha waxing

Umngxuma ongaphakathi wotyalo-mali oluchanekileyo uye wagalelwa, nto leyo eshiya umngxuma ongaphandle umaleko weqokobhe leceramic. Imingxunya iyindawo nje efanayo naleyo ifunwayo.

6-Uhlalutyo lokugalela kwangaphambili

Uhlalutyo lokugalelwa kwangaphambili luthetha ukuba i-Foundry idinga ukujonga kunye nokuhlalutya ukwakheka kweekhemikhali zesinyithi esityhidiweyo ukubona ukuba ziyahlangabezana na namanani afunekayo okanye istardard. Ngamanye amaxesha, olu hlalutyo luya kwenziwa amaxesha amaninzi.

7- Ukugalela kunye nokuqinisa

Igobolondo ye-ceramic ene-cavity kufuneka ifudunyezwe kwangaphambili ngaphambi kokugalela. Oku kuthintela ukothuka kunye neqokobhe le-ceramic ekuqhekekeni kanye xa isinyithi solwelo kwiqondo lobushushu obuphezulu sigalelwa kumngxunya.

8- Ukusarha okanye Ukusika

Nje ukuba intsimbi ipholile kwaye yomelele, i(ii)ndawo ezityhidiweyo ziyasuswa kwinkqubo yokusalela iqoqo lomthi ngokungcangcazela, ukusika okanye ukukhuhlana kwesarha kwindawo ephosiweyo.

9- Ukudutyulwa kokudubula kunye nokuLungiswa kweSekondari

Inxalenye yokuphosa ilungiselelwe ngokupheleleyo ngokusila okanye unyango olongezelelweyo lobushushu. Umatshini wesibini okanye unyango lwangaphezulu lunokufuneka ngokuxhomekeke kwiimfuno zenxalenye.

10-Ukupakisha kunye nokuhanjiswa

Emva koko iindawo ezilahlekileyo zokuphosa i-wax ziya kuvavanywa ngokupheleleyo kwimilinganiselo, umphezulu, iipropati zomatshini kunye nezinye iimvavanyo ezifunekayo ngaphambi kokupakisha kunye nokuhanjiswa.

Iipateni zeWax

Ukomisa iqokobhe

Ukupholisa kunye nokuqinisa

Ukusila nokuCoca

SiluHlola Njani uTyalo mali

- • Uhlalutyo lwe-Spectrographic kunye nencwadana yobungakanani

- • Uhlalutyo lwe-metallographic

- • Iimvavanyo zobukhulu

- • CMM

- • Ukuhlolwa kokuqina kweBrinell, Rockwell kunye noVickers

- • Uhlalutyo lwepropathi yoomatshini

- • Uvavanyo lwefuthe lobushushu obuphantsi noluqhelekileyo

- • Ukuhlolwa kococeko

- • Ukuhlolwa kwe-UT, MT kunye neRT

- • I-Staic and Dynamic Balancing

- • Ukutywinwa kunye noVavanyo loxinzelelo

Wax Replicas

Zeziphi iZibonelelo esithembele kuzo kuTyalo-mali lokuCasa

Toolings Warehouse

Iipateni zewax Isitofu

Iipateni zewax Isitofu

Umatshini wokutofa ngeWax

Ukwenza iqokobhe

Ukwenza iqokobhe

Iworkshop yokomisa iqokobhe

I-Shell yoTyalo-mali lokuCasa

Ukomisa iqokobhe

Iqokobhe Lilungele ukuSasa

Ukupholisa kunye nokuqinisa

Inkqubo yoTyalo mali

Ngawaphi amaShishini oTyalo-mali lwethu oluSebenzayo

Izahlulo ezenziwe ngotyalo-malizisetyenziselwa ukuphosa izinto ezininzi ezahlukeneyo, kubandakanywa umgangatho ophezulu, iindawo zoshishino eziphezulu zezakhiwo ezinzima.Ukusetyenziswa kwamacandelo okuphosa utyalo-mali kubandakanya uluhlu olubanzi lwamashishini, kwinkampani yethu aqhele ukusetyenziswa kwezi ndawo zilandelayo:

| •I-Valve kunye neeMpampu zeNgxelo | • Izixhobo zokusebenza |

| • Iilori ezisebenza nzima | • IZixhobo zezoLimo |

| • Iimoto | •Iihydraulics |

| • Izixhobo zokwakha | • Oololiwe bakaloliwe |

Izicelo zoTyalo-mali Castings

IsiqheloInvestment CastingsSiyavelisa

Singenza Okungakumbi ngokunikezela ngoTyalo-mali lokuCasa kunye nezinye iiNkonzo:

E-RMC, siyazingca ngokunika abathengi bethu inkonzo ukusuka kuyilo lwepatter ukuyaukugqiba ukutyakunye neenkqubo zesibini. Iinkonzo zethu ziquka:

- - Uyilo lwepateni kunye neeNgcebiso zeendleko eziphantsi.

- - Uphuhliso loMfanekiso.

- - Uphando lweMveliso kunye noPhuhliso.

- - Ukuguquguquka kokuVeliswa.

- -Isiqinisekiso kunye noVavanyo.

- - Unyango loBubushushu kunye noNyango oluphezu komhlaba luyafumaneka.

- -Ukunikezela ngezakhono zokuVelisa

I-Stainless Steel Investment Castings

Kutheni ukhetha i-RMC yokuVelisa iiCastings zoTyalo-mali

Kukho izizathu ezininzi zokukhetha i-RMC njengomthombo wakho wotyalo-mali. Xa usenza isigqibo, unokukhathalela ezi ngongoma zilandelayo esizisebenzelayo:

- - Iqela lobunjineli elinamalungu agxile kwibala lokuphosa isinyithi.

- - Amava abanzi aneenxalenye zejometri ezintsonkothileyo

- - Uluhlu olubanzi lwezixhobo, kubandakanywa i-alloys ye-ferrous kunye ne-non-ferrous

- - EndlwiniCNC machiningizakhono

- -Izisombululo zokumisa enye yotyalo-mali kunye nenkqubo yesibini

- - Umgangatho ongaguqukiyo uqinisekisiwe kunye nophuculo oluqhubekayo.

- -Intsebenziswano ebandakanya abenzi bezixhobo, iinjineli, umyili, umchweli kunye namagcisa emveliso.