Zombini i-iron engwevu kunye ne-ductile iron inokuphoswa ngayoinkqubo yokugalela isanti, inkqubo yokubumba iqokobhe (intlabathi egqunywe intlaka), ukuphosa amagwebu alahlekileyo, ukufunxa kunye nokuphosa utyalo-mali. Ukuphoswa kwesanti yenye yezona ntlobo zidumileyo nezilula zokuphosa. Ukuchithwa kwesanti kuvumela iibhetshi ezincinci kunokubunjwa ngokusisigxina kwaye ngexabiso elifanelekileyo kakhulu. Le ndlela ayivumeli kuphela abavelisi ukuba benze iimveliso ngexabiso eliphantsi, kodwa kukho ezinye iingenelo zokugalela isanti, ezifana nemisebenzi encinci kakhulu. Ukugaywa kwesanti kukwavumela ukuba iintsimbi ezininzi zijulwe, kuxhomekeke kuhlobo lwesanti esetyenziselwa ukubumba. Inkqubo yokubumba iqokobhe ikwabizwa ngokuba yinkqubo yokugalela isanti yentlabathi eqatywe ngaphambili, ukubunjwa kweqokobhe elishushu okanye inkqubo yokuphosa engundoqo. Izinto eziphambili zokubumba yintlabathi ye-phenolic resin efakwe ngaphambili, ebiza kakhulu kunesanti eluhlaza kunye nesanti ye-furan resin. Ngaphezu koko, le santi ayinakuphinda isetyenziswe. Iindawo zokugalela intsimbi yokubumba iqokobhe zineendleko eziphezulu kunesanti. Nangona kunjalo, iiqokobhe lokubumba iindawo zokugalelazineenzuzo ezininzi ezifana nokunyamezelana okuqinileyo, umgangatho olungileyo womphezulu kunye neziphene ezincinci zokuphosa.

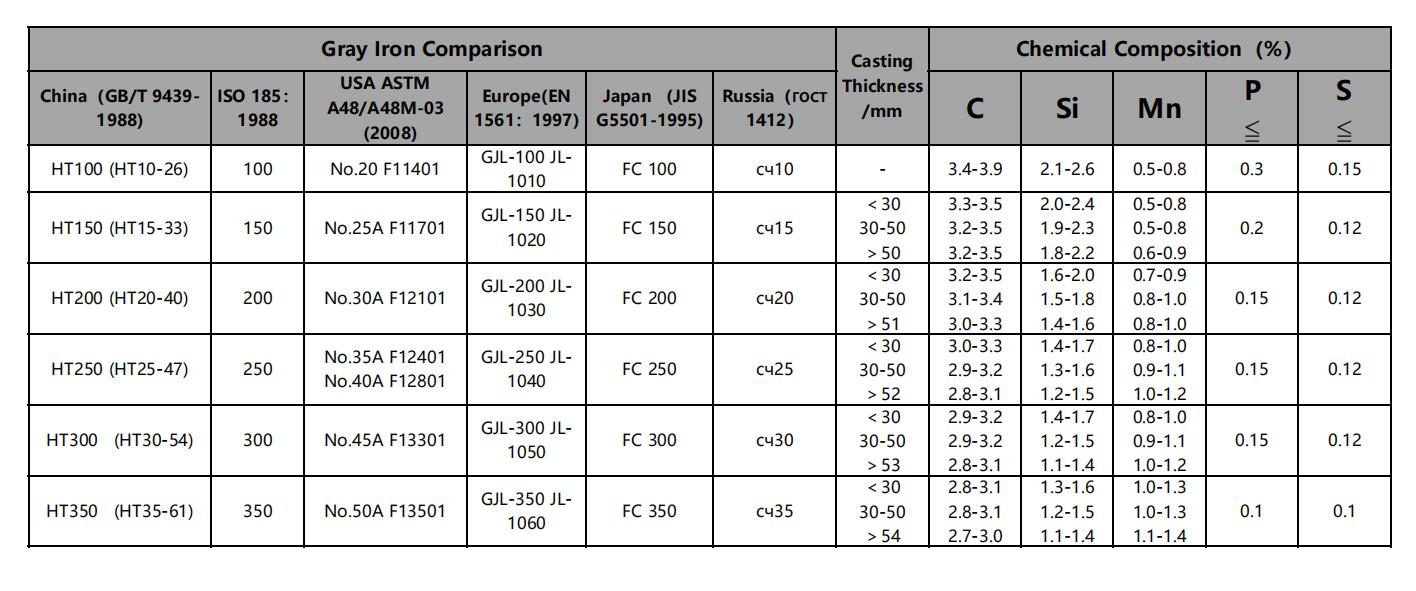

Nangona kunjalo, kusekho iiyantlukwano phakathi kweendawo zokuphosa intsimbi engwevu kunye neendawo zokuphosa intsimbi.Grey Iron Sand Castingisetyenziswa rhoqo ukwenza iimilo ezintsonkothileyo ezinokuthi ngenye indlela zibenzima okanye zingabinamali ukuzenza ngezinye iinkqubo zokubumba isinyithi. Ngenxa yokulula kwayo ukwenza oomatshini, amandla acinezelayo aphezulu, ukuguquguquka okungcono kwe-thermal kunye nokufunxa okugqwesileyo kwe-vibration, intsimbi engwevu yentsimbi yenye yezona zinto zisetyenziswa kakhulu ukuphosa isinyithi ixesha elide, nakwimveliso yangoku yoshishino. Umxholo wekhabhoni yeyona nto ibaluleke kakhulu kwi-iron engwevu (idla ngokuba yi-2% ukuya kwi-4%) ukwenza amandla okuqina kunye nokusebenza. Xa isinyithi esinyibilikisiweyo siqinisa enye i-carbon precipitates njengegraphite, isenza iiflakes ezincinci, ezingaqhelekanga ngaphakathi kolwakhiwo lwekristale yentsimbi ephucula iipropati ezinqwenelekayo zentsimbi etyhidiweyo, iiflakes ziphazamisa ulwakhiwo lwekristale olukhokelela kubume bentsimbi.

Uphuhliso lwentsimbi engwevu luqhutywa ngamandla amakhulu. Ngaphambili, indlela ephambili yokuphucula ukusebenza kwe-iron grey cast inoculation. Kwiminyaka yakutshanje, eyona ndlela iphambili ngoku kukugxila kwi-alloying, kwaye ukuze kuphuculwe ukusebenza kwe-casting, ezininzi ii-iron grey foundries zisebenzisa i-cast iron kunye ne-carbon equivalent. Oku kubaluleke kakhulu kwintsimbi ephantsi ye-alloy cast. Ke ngoko, isinyithi esingwevu sisixhobo esifanelekileyo sokuvelisa iindawo zokugalela intsimbi kwibhloko yenjini, izindlu zoomatshini, isiseko soomatshini, iintsimbi zokubala, iinxalenye zesitovu, iinxalenye zebhoyila, iigobolondo zempompo njalo njalo.

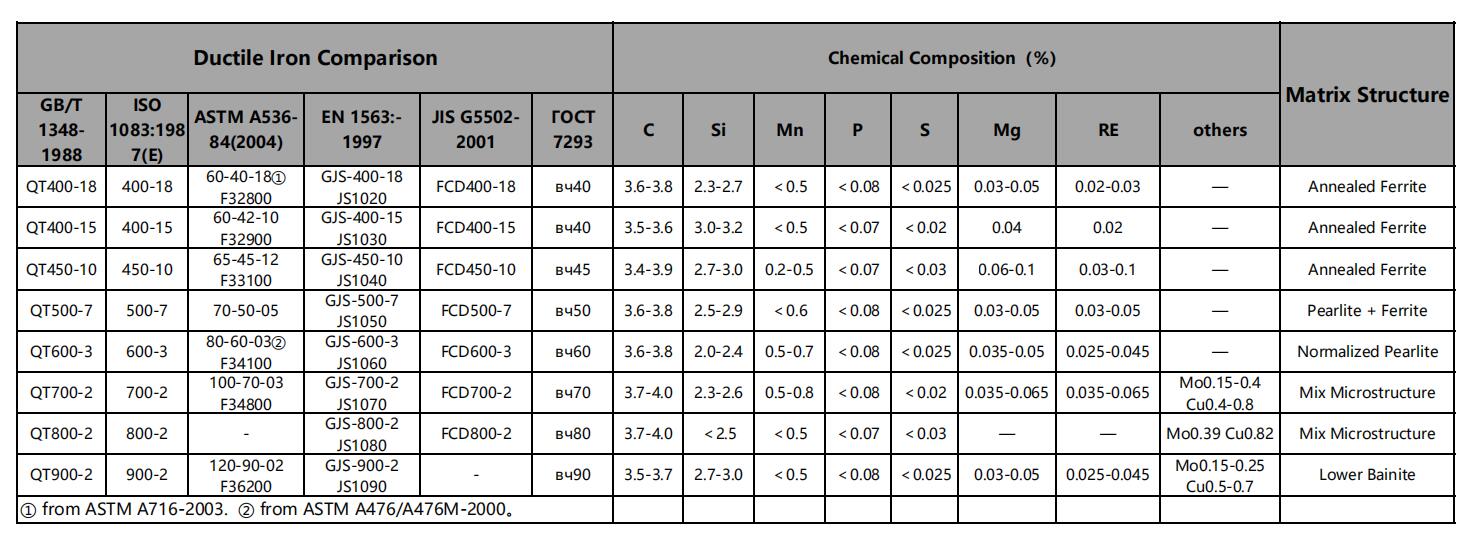

Intsimbi yentsimbi ibonelela ngobubhetyebhetye boyilo kunye neendleko ezincitshisiweyo zokwenziwa xa kuthelekiswa nezakhiwo ezidityanisiweyo kunye nokubunjwa. Kwi-microstructure ye-iron ductile, i-graphite ifom ibe ngamaqhuqhuva angama-spherical endaweni yee-flakes, ngaloo ndlela inqanda ukudalwa kweentanda kunye nokubonelela nge-ductility ephuculweyo enika i-alloy igama layo. Intsimbi ye-Ductile inamandla aphezulu kunye nokuqina okufana nentsimbi.Ukujulwa kwentsimbi yentsimbizineempawu ezininzi, nangona kunjalo, azisoloko zezona zingabizi kakhulu enye ialloyi yeferrous. Ukongeza, ii-iron ze-ductile zisetyenziswa ngokubanzi kumashishini amaninzi okuvelisa, kubandakanya ezolimo, iimoto, ii-hydraulics, oololiwe bakaloliwe, iilori zorhwebo kunye nemizi-mveliso ye-aerospace.

Ixesha lokuposa: Jan-27-2021