Intsimbi enganyangekiyo ekunxityweni (okanye i-abrasion-resistant) ibhekisa kwintsimbi ekhutshiweyo enokumelana nokunxiba kakuhle. Ngokokwakheka kweekhemikhali, yahlulwe kwi-non-alloy, i-alloy ephantsi kunye ne-alloy wear-resistant cast cast. Zininzi iintlobo zentsimbi engagungqiyo, enokuthi yahlulwe ngokuthe ngqo ukuba yintsimbi ephezulu-manganese, intsimbi ephakathi kunye nesezantsi, intsimbi ye-chromium-molybdenum-silicon-manganese, intsimbi enganyangekiyo kwi-cavitation, intsimbi engagungqiyo, kunye nentsimbi ekhethekileyo yokunxiba. Ezinye iintsimbi eziqhelekileyo ze-alloy ezifana nensimbi engenasici, intsimbi yokuthwala, insimbi yensimbi ye-alloy kunye ne-alloy structural steel nazo zisetyenziswa njengentsimbi engagungqiyo phantsi kweemeko ezithile.

Iintsimbi ezikwazi ukumelana neentsimbi eziphakathi nezisezantsi zihlala zinemichiza efana nesilicon, manganese, chromium, molybdenum, vanadium, tungsten, nickel, titanium, boron, copper, umhlaba onqabileyo, njl njl. Izingqusho eUnited States zenziwe ngechromium-molybdenum-silico-manganese okanye intsimbi yechromium-molybdenum. Uninzi lweebhola zokugaya e-United States zenziwe ngentsimbi ephakathi kunye nephezulu ye-carbon chromium molybdenum. Kwizixhobo zokusebenza ezisebenza phantsi kobushushu obuphezulu ngokwentelekiso (umzekelo, 200~500℃) iimeko zokunxiba ezirhabaxa okanye iindawo zazo ziphantsi kobushushu obuphezulu ngenxa yobushushu obukhukhulayo, iialloyi ezifana nechromium molybdenum vanadium, chromium molybdenum vanadium nickel okanye i-chromium vanadium tubdengde inokusetyenziswa.

I-Abrasion yinto eyenzeka apho izinto ezikumphezulu wokusebenza wento zitshatyalaliswa ngokuqhubekayo okanye ziphulukene nentshukumo ehambelanayo. Ukwahlulwe yindlela yokunxiba, ukunxiba kunokohlulwa kube kukunxitywa kwe-abrasive, ukunxiba okuncamathelayo, ukunxitywa kwe-corrosion, ukunxitywa kokhukuliseko, ukudinwa kokunxibelelana, ukunxitywa kwempembelelo, ukunxitywa kwe-fretting kunye nezinye iindidi. Kwintsimi yemizi-mveliso, ukunxitywa kwe-abrasive kunye nokuncamatheliswa kweakhawunti yeyona nxalenye inkulu yokusilela kokunxiba kwesixhobo sokusebenza, kunye neendlela zokusilela zokunxiba ezinje ngokhukuliseko, ukubola, ukudinwa, kunye nokukhathazeka kuqhele ukwenzeka ekusebenzeni kwamanye amacandelo abalulekileyo, ngenxa yoko bayanda ngakumbi. kunye nokuqwalaselwa ngakumbi. Ngaphantsi kweemeko zokusebenza, iintlobo ezininzi zokugqoka zivame ukubonakala ngexesha elinye okanye enye emva komnye, kwaye intsebenziswano yokungaphumeleli kokugqoka ithatha ifom enzima ngakumbi. Ukumisela uhlobo lokungaphumeleli kokugqoka kwi-workpiece yisiseko sokhetho olufanelekileyo okanye uphuhliso lwentsimbi engagungqiyo.

Ukongeza, ukunxiba kwamalungu kunye namacandelo yingxaki yobunjineli benkqubo. Kukho izinto ezininzi ezichaphazela ukugqoka, kubandakanywa iimeko zokusebenza (umthwalo, isantya, imo yokunyakaza), iimeko zokuthambisa, iimeko zokusingqongileyo (umswakama, ubushushu, imidiya engqongileyo, njl. umgangatho kunye neempawu zomzimba kunye neekhemikhali zamalungu. Utshintsho kwinto nganye kwezi lunokutshintsha ubungakanani bokunxitywa kunye nokutshintsha indlela yokunxiba. Ingabonwa ukuba into ebonakalayo yinto enye kuphela yezinto ezichaphazela ukunxiba kwe-workpiece. Ukuphucula ukunyanzeliswa kokugqoka kweengxenye zetsimbi, kuyimfuneko ukuqala nge-friction jikelele kunye nenkqubo yokugqoka phantsi kweemeko ezithile ukufezekisa umphumo oyifunayo.

1. Isisombululo soNyango loBubushushu (uNyango lokuGunyaza amanzi) loKulahlwa kweNtsimbi yeManganese eNganyangekiyo

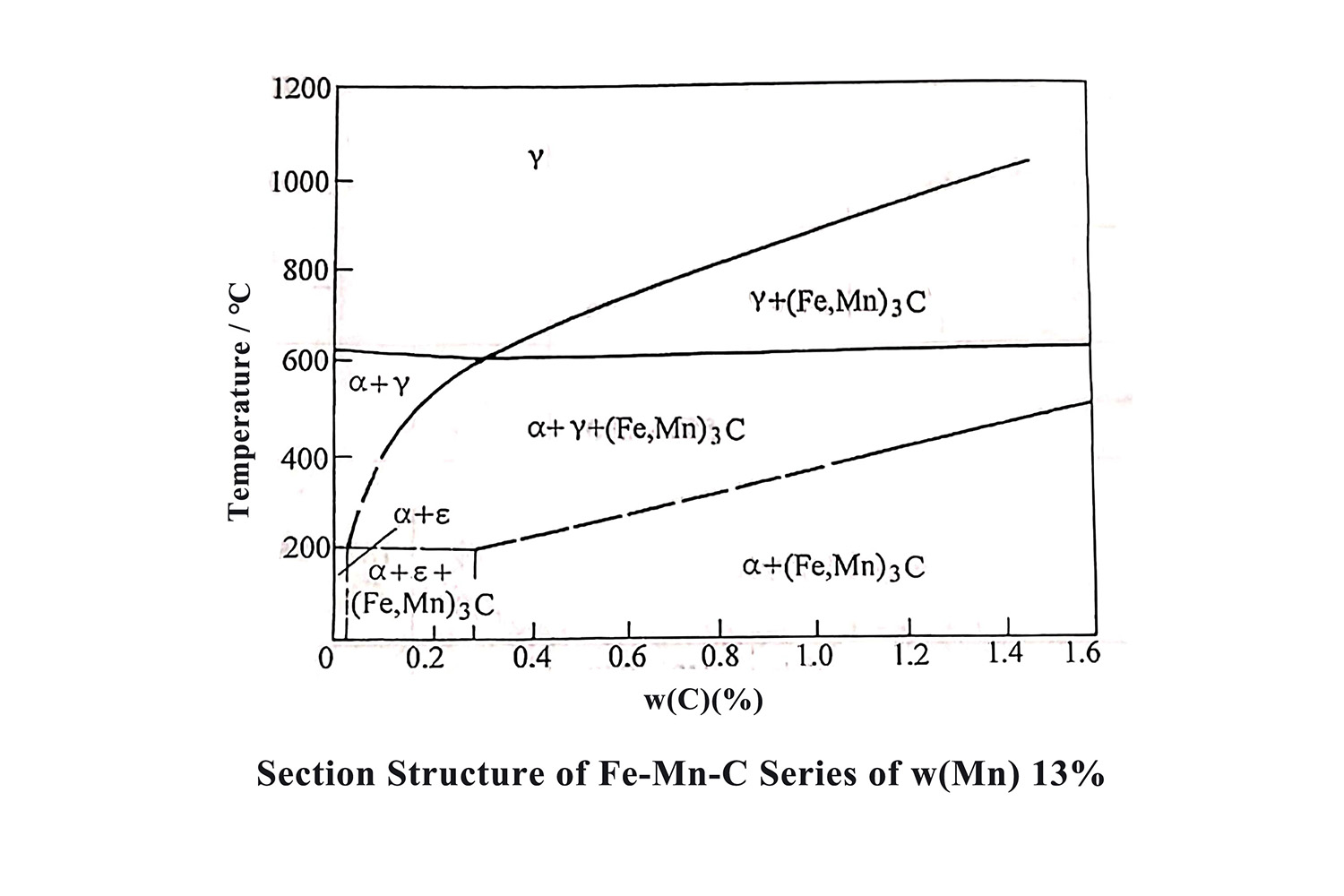

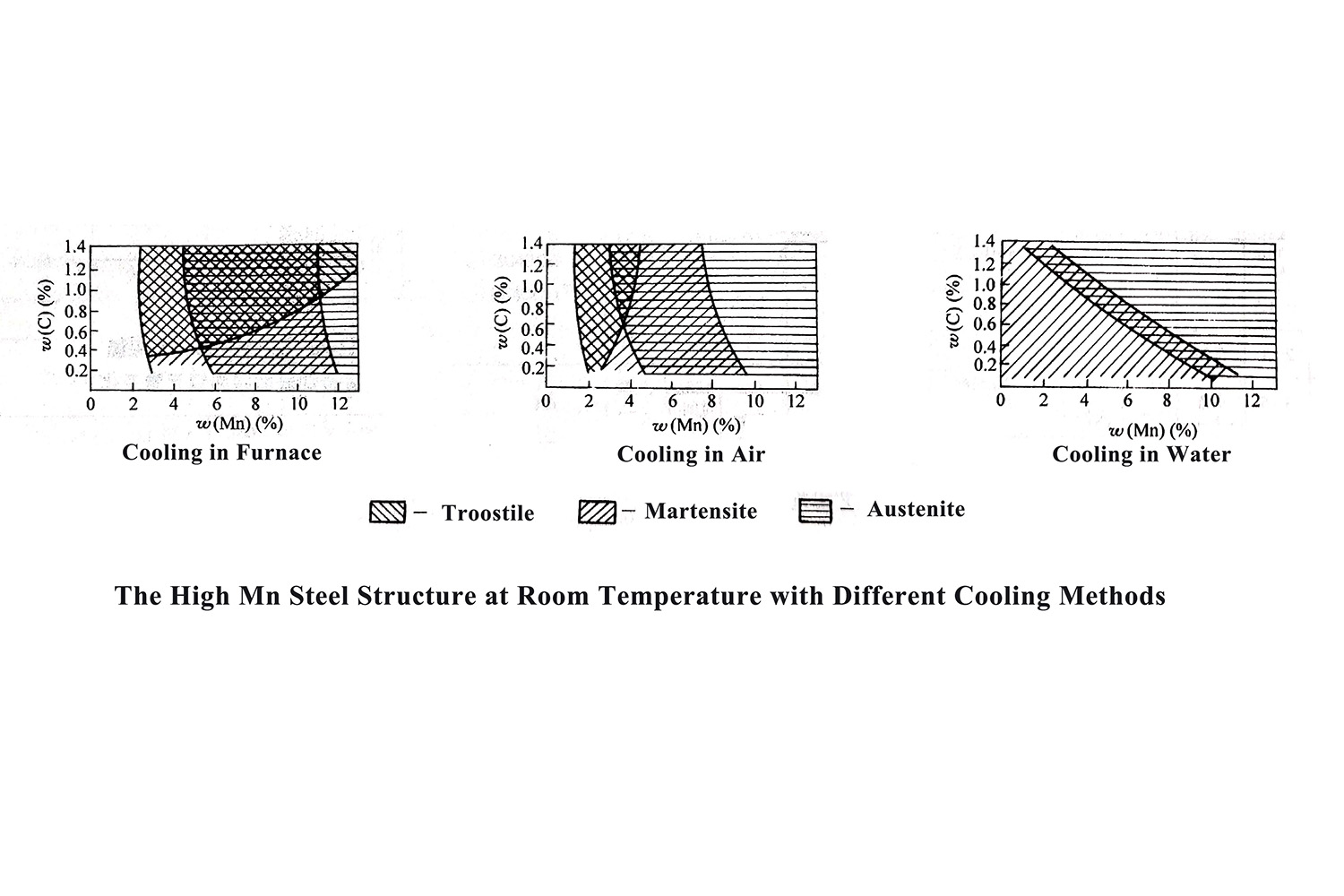

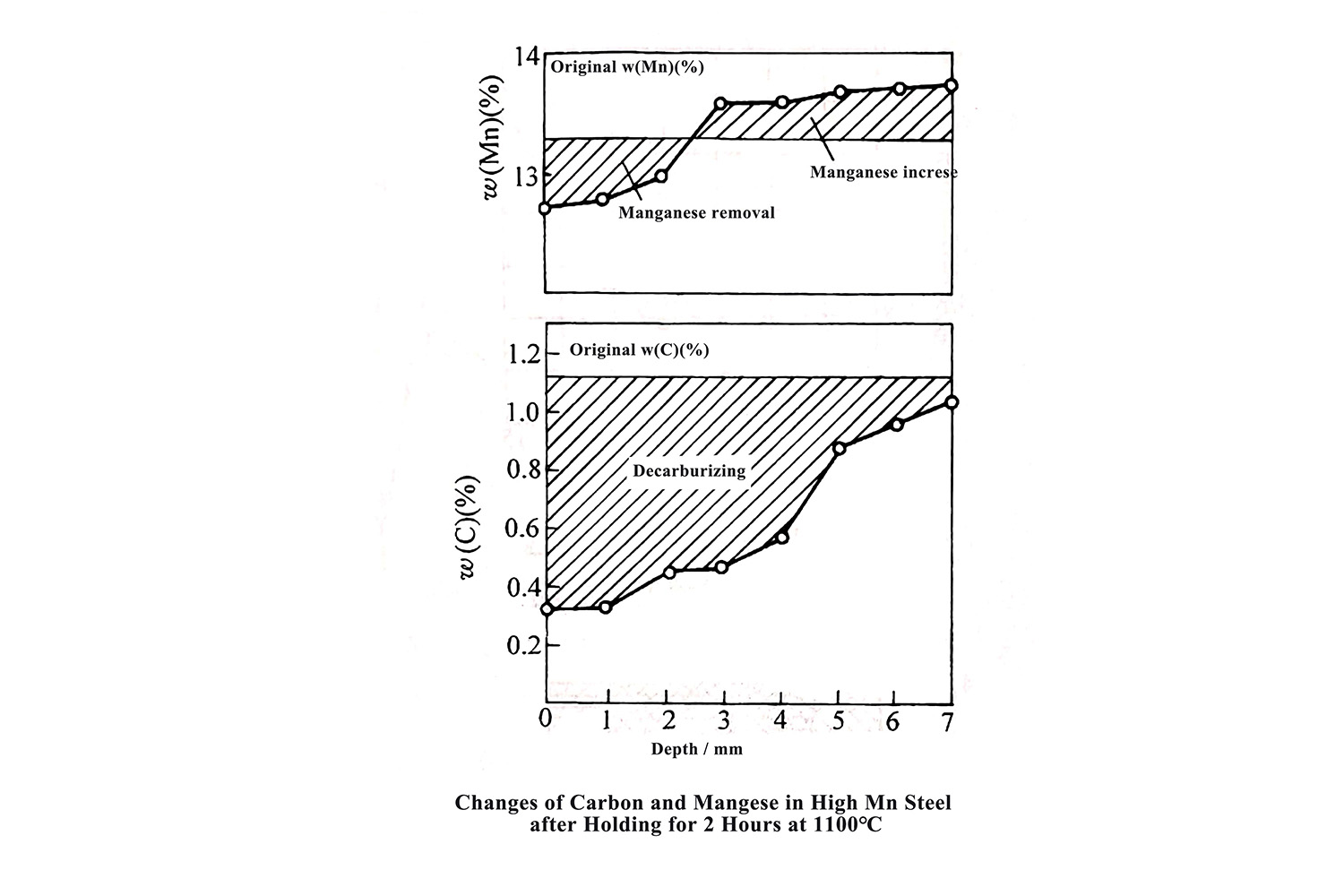

Kukho inani elikhulu lee-carbides ezinqambileyo kwisakhiwo se-as-cast of the wear-resistant high-manganese steel. Ezi carbides ziya kunciphisa ukuqina kokuphosa kwaye zenze kube lula ukuphuka ngexesha lokusetyenziswa. Injongo ephambili yokulungiswa kokushisa kwesisombululo sentsimbi ephezulu ye-manganese kukuphelisa i-carbides kwisakhiwo se-as-cast kunye nakwimida yeenkozo ukufumana isakhiwo se-austenite sesigaba esisodwa. Oku kunokuphucula amandla kunye nokuqina kwentsimbi ephezulu ye-manganese, ukwenzela ukuba iintsimbi eziphezulu ze-manganese zilungele uluhlu olubanzi lwamasimi.

Ukulungiswa kobushushu besisombululo sentsimbi enganyangekiyo kwintsimbi ephezulu yemanganese inokwahlulwa ngokwamanqanaba aliqela: ukufudumeza iicastings ukuya ngaphezulu kwe-1040 ° C kwaye uzibambe ngexesha elifanelekileyo, ukuze i-carbides ekuyo inyibilikiswe ngokupheleleyo kwisigaba esinye se-austenite. ; ke ngokukhawuleza ukupholisa , Fumana austenite isisombululo esomeleleyo isakhiwo. Olu nyango lwesisombululo lukwabizwa ngokuba yi-water toughening treatment.

(1) Ubushushu bonyango lokuqina kwamanzi

Ubushushu bokuqina bamanzi buxhomekeke kukwakheka kweekhemikhali zentsimbi ephezulu yemanganese, idla ngokuba yi-1050℃-1100℃. Iintsimbi eziphezulu ze-manganese ezinomxholo ophezulu wekhabhoni okanye umxholo ophezulu we-alloy (njenge-ZG120Mn13Cr2 yentsimbi kunye ne-ZG120Mn17 yensimbi) kufuneka ithathe umda ophezulu wokushisa kwamanzi. Nangona kunjalo, ubushushu obugqithisileyo bamanzi obuphezulu buya kubangela ukubola okuqatha kumphezulu wokugalela kunye nokukhula okukhawulezayo kweenkozo zentsimbi zemanganese, okuya kuchaphazela ukusebenza kwentsimbi ephezulu yemanganese.

(2) Izinga lobushushu bonyango lokuqina kwamanzi

I-thermal conductivity yensimbi ye-manganese imbi ngakumbi kuneyentsimbi yekhabhoni jikelele. I-high-manganese castings yensimbi inoxinzelelo oluphezulu kwaye kulula ukuyiqhekeza xa ishushu, ngoko ke izinga lokufudumeza kufuneka limiselwe ngokobunzima bodonga kunye nokuma kwe-casting. Ngokuqhelekileyo, i-castings enobunzima obuncinane bodonga kunye nesakhiwo esilula sinokufudumala ngokukhawuleza ngokukhawuleza; iicastings ezinobunzima obukhulu bodonga kunye nesakhiwo esiyinkimbinkimbi kufuneka sifudunyezwe ngokukhawuleza. Kweyona nkqubo yonyango lobushushu, ukuze kuncitshiswe ukuguqulwa okanye ukuqhekeka kokuphosa ngexesha lenkqubo yokufudumeza, ifudunyezwa ngokubanzi malunga ne-650 ℃ ukugcina umahluko wobushushu phakathi kwangaphakathi nangaphandle kokuphoswa kuncitshisiwe, kunye nobushushu ngaphakathi. i-furnace iyunifomu, kwaye ngokukhawuleza inyuke kwiqondo lokushisa lobunzima bamanzi.

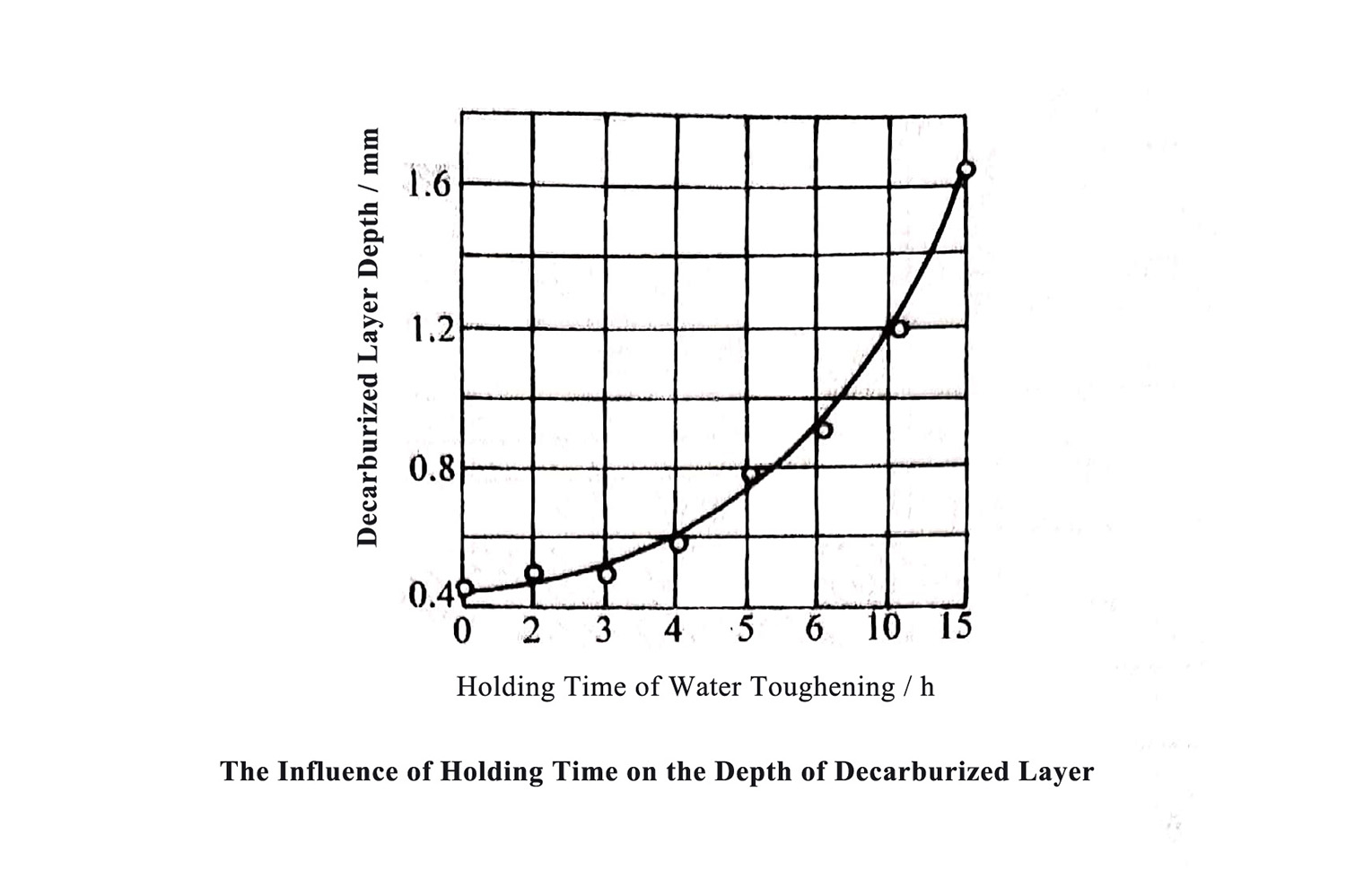

(3) Ukubamba ixesha lonyango lokuqina kwamanzi

Ixesha lokubamba unyango lokunyanzeliswa kwamanzi luxhomekeke kubukhulu bodonga lokuphosa, ukwenzela ukuba kuqinisekiswe ukuchithwa okupheleleyo kwe-carbides kwisakhiwo se-as-cast kunye ne-homogenization yesakhiwo se-austenite. Kwiimeko eziqhelekileyo, ingabalwa ngokunyusa ixesha lokubamba ngeyure eli-1 kwi-25 mm yokwanda kwendonga.

(4) Ukupholisa unyango lokuqina kwamanzi

Inkqubo yokupholisa inempembelelo enkulu kwisalathiso sokusebenza kunye nesakhiwo sokuphosa. Ngethuba lokunyangwa kwamanzi, ubushushu bokuphosa ngaphambi kokungena emanzini kufuneka bube ngaphezu kwe-950 ° C ukukhusela i-carbides ukuba iphinde iphinde iphinde iphinde ibe yimvula. Ngenxa yesi sizathu, ikhefu lexesha phakathi kokukhupha ngaphandle kwesithando somlilo kunye nokungena emanzini akufanele lidlule imizuzwana engama-30. Ubushushu bamanzi kufuneka bube ngaphantsi kwe-30 ° C ngaphambi kokuba ukuphosa kungene emanzini, kwaye ubushushu obukhulu bamanzi emva kokungena emanzini akufanele budlule i-50 ° C.

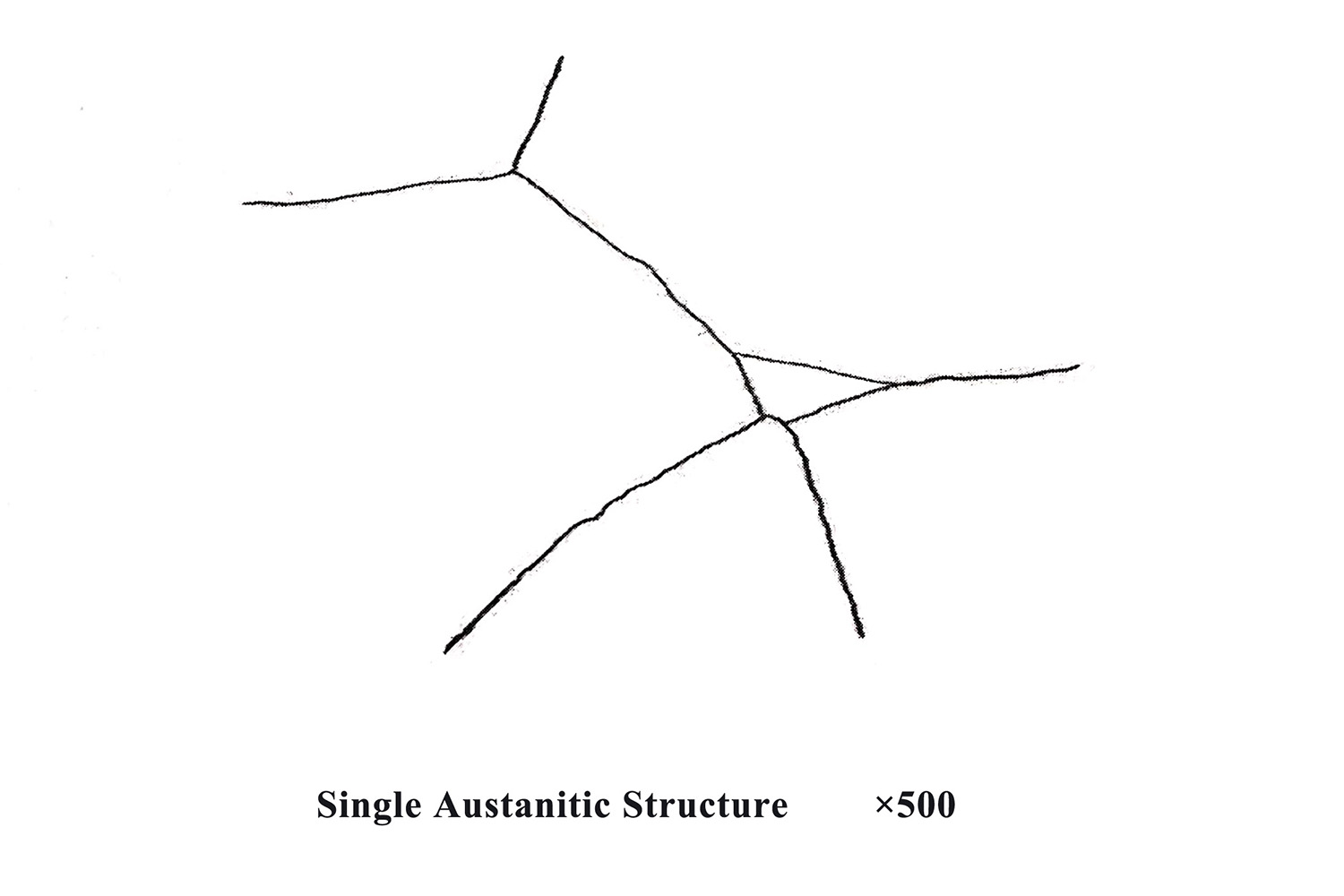

(5) Carbide emva unyango toughening amanzi

Emva kokunyangwa kwamanzi, ukuba i-carbides kwintsimbi ephezulu ye-manganese iphelile ngokupheleleyo, isakhiwo se-metallographic esifunyenwe ngeli xesha sisakhiwo esisodwa se-austenite. Kodwa isakhiwo esinjalo sinokufumaneka kuphela kwii-castings ezinodonga oluncinci. Ngokuqhelekileyo, inani elincinci le-carbides kwiinkozo ze-austenite okanye kwimida yengqolowa ivumelekile. I-carbides engachithwanga kunye ne-precipitated carbides inokupheliswa ngonyango lokushisa kwakhona. Nangona kunjalo, i-eutectic carbides efunyenwe ngenxa yobushushu obugqithisileyo ngexesha lonyango lokuqina kwamanzi ayamkelekanga. Ngenxa yokuba i-eutectic carbide ayikwazi ukupheliswa ngonyango lokushisa kwakhona.

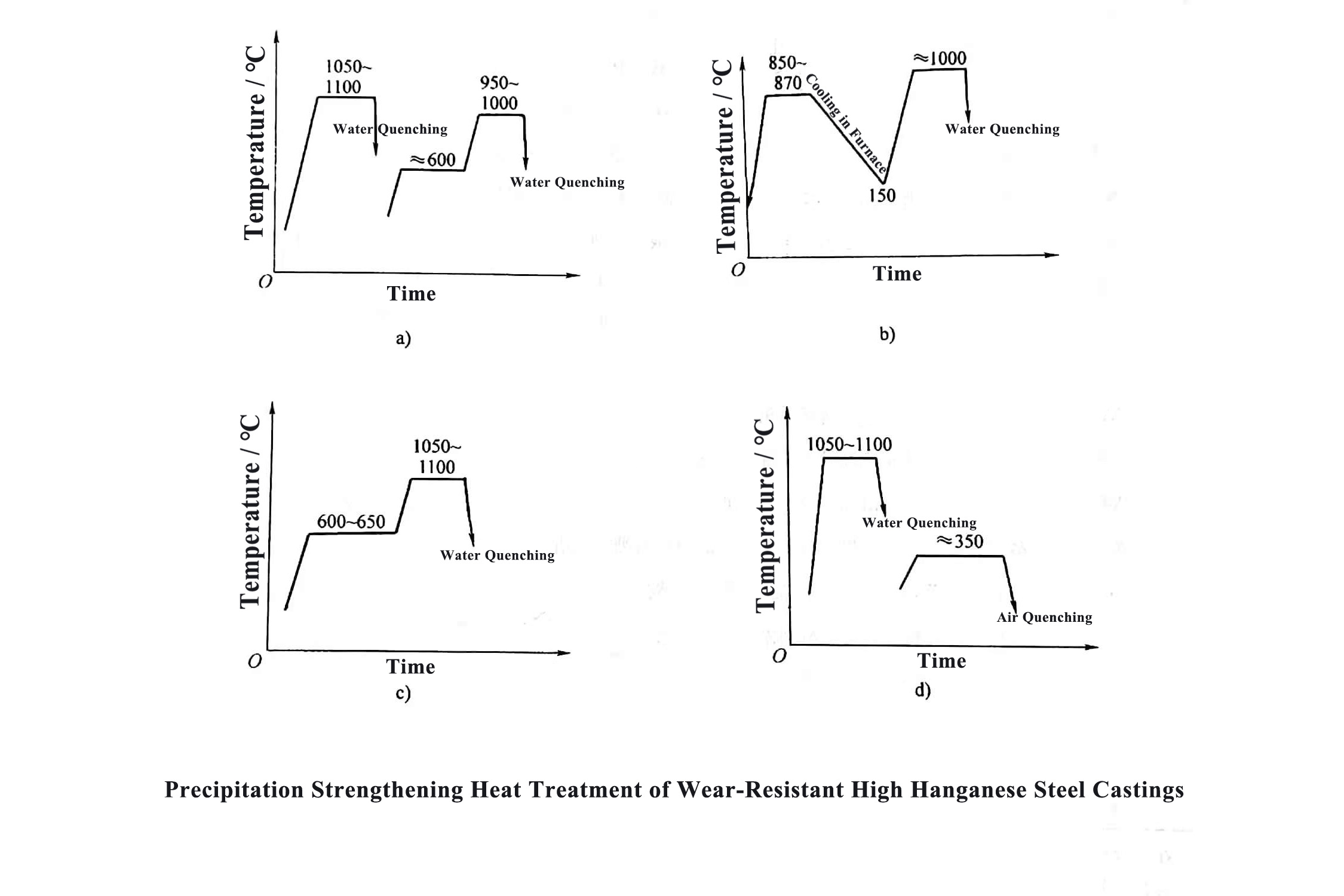

2. Imvula eyomeleza uNyango loBubushushu boKulahlwa kwentsimbi ye-Hanganese eNganyangekiyo

Ukomeleza imvula yonyango lobushushu obunganyangekiyo kwintsimbi ephezulu yemanganese ibhekisa ekongezweni kwesixa esithile sezinto ezenza i-carbide (ezifana ne-molybdenum, tungsten, vanadium, titanium, niobium kunye nechromium) ngonyango lobushushu ukufumana isixa esithile kunye nobukhulu intsimbi ephezulu ye-manganese Isigaba sesibini samasuntswana e-carbide ahlakaziweyo. Olu nyango lobushushu lunokomeleza i-matrix ye-austenite kunye nokuphucula ukuxhathisa ukunxiba kwentsimbi ephezulu ye-manganese.

3. UNyango loBubushushu lweziNsimbi zeChromium eziNxibelelayo eziNxibelelayo

Injongo yonyango lobushushu lwentsimbi ye-chromium ekwazi ukumelana nokunxiba kukufumana ulwakhiwo lwe-matrix ye-martensite enamandla amakhulu, ukuqina kunye nobunzima obuphezulu, ukuze kuphuculwe amandla, ukuqina kunye nokumelana nokunxiba kweentsimbi zentsimbi.

Intsimbi yechromium enganxibiyo ephakathi inezinto ezininzi zechromium kwaye inokuqina okuphezulu. Ngoko ke, indlela yayo eqhelekileyo unyango ubushushu: emva 950 ℃-1000 ℃, austenitization yayo, emva koko ucime unyango, kunye nonyango kwangethuba tempering (ngokuqhelekileyo 200-300 ℃).

4. Ukunyangwa kobushushu kwi-Wear-Resistant Low-Alloy Steel Castings

Iintsimbi eziphantsi kwe-alloy-resistant-resistant-alloy castings ziphathwa ngokucima emanzini, ukucima ioli kunye nokucima umoya ngokuxhomekeke kwi-alloy composition kunye nomxholo wekhabhoni. I-Pearlitic inxibe-resistant intsimbi yokuphosa ithatha isiqhelo + sonyango lobushushu.

Ukuze ufumane i-matrix ye-martensite enamandla amakhulu, ukuqina kunye nokuqina, kunye nokuphucula ukunyanzeliswa kokuxhatshazwa kwensimbi, ukuchithwa kwensimbi ephantsi kwe-alloy ephantsi ngokuqhelekileyo kucinywa kwi-850-950 ° C kwaye iyancipha kwi-200-300 ° C. .

Ixesha lokuposa: Aug-07-2021