I-electrocoating ye-Industrial isetyenziswa ngokubanzi kunyango lomphezulu wokukhuselaiintsimbi zentsimbikunye neemveliso zomatshini ze-CNC ezivela kumhlwa kunye nokugqiba okuhle. Abathengi abaninzi babuza imibuzo malunga nokunyangwa komphezulu wesinyithi kunyeiindawo zoomatshini ezichanekileyo. Eli nqaku liza kugxininisa kwinkqubo yokugqoka i-electrophoretic. Ndiyathemba ukuba iya kuba luncedo kuwo onke amaqabane.

I-Electrocoating yindlela yokugqoka apho iinqununu ezinjengee-pigments kunye ne-resin ezimisiwe kwisisombululo se-electrophoretic zijoliswe ukuba zifuduke kwaye zifake phezu kwendawo enye ye-electrodes ngokusebenzisa intsimi yangaphandle yombane. Umgaqo we-electrophoretic coating waqanjwa ekupheleni kweminyaka ye-1930, kodwa le teknoloji yaphuhliswa kwaye yafumana ukusetyenziswa kwemizi mveliso emva kwe-1963. I-Electrophoretic coating yinkqubo yokwakha eyona nto isebenzayo yokwaleka kwamanzi. I-Electrophoretic coating ineempawu zokunyibilika kwamanzi, ukungabi nabutyhefu, kunye nokulawula okulula okuzenzekelayo. Ngenxa yokuba ilungele ukunyangwa komphezulu wezinto ezisebenzayo (intsimbi, iinxalenye zoomatshini, i-forgings, iinxalenye zentsimbi kunye neendawo zokuwelda, njl.njl.), inkqubo yokwambathisa i-electrophoretic isetyenziswe ngokukhawuleza kumashishini anje ngeemoto, izixhobo zokwakha, izixhobo zentsimbi. , kunye nezixhobo zasekhaya.

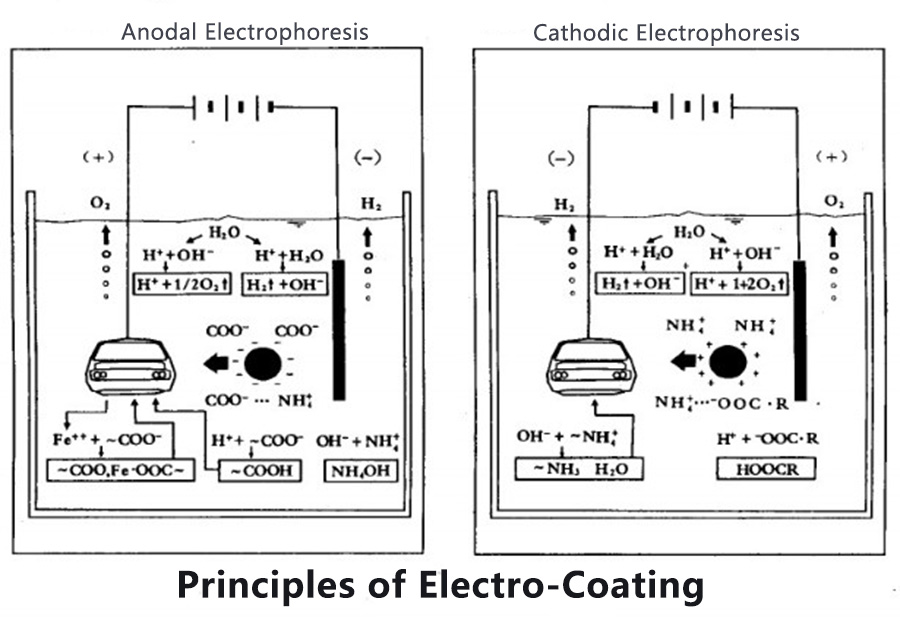

Imigaqo

I-resin equlethwe kwi-cathodic electrophoretic coating inamaqela asisiseko, enza ityuwa emva kokungathathi hlangothi kwe-asidi kwaye ichithe emanzini. Emva kokuba i-current isetyenzisiwe, i-asidi e-radical negative ion ifudukela kwi-anode, kunye ne-resin ion kunye ne-pigment particles ezisongwe ngazo zihamba kwi-cathode kunye neentlawulo ezilungileyo kwaye zifakwe kwi-cathode. Lo ngumgaqo osisiseko we-electrophoretic coating (eyaziwa ngokuba yi-plating). I-Electrophoresis coating yi-electrochemical reaction eyinkimbinkimbi kakhulu, ubuncinane imiphumo emine ye-electrophoresis, i-electrodeposition, i-electrolysis, kunye ne-electroosmosis zenzeka ngaxeshanye.

Electrophoresis

Emva kokuba i-anode kunye ne-cathode kwisisombululo se-colloidal iqhutywe, iinqununu ze-colloidal zihamba kwicala le-cathode (okanye i-anode) phantsi kwesenzo sommandla wombane, obizwa ngokuba yi-electrophoresis. I-substance kwisisombululo se-colloidal ayikho kwimeko ye-molecule kunye ne-ion, kodwa i-solute ihlakazwe kulwelo. I-substance inkulu kwaye ayiyi kudlula kwimo esasazekileyo.

Electrodeposition

Isenzeko semvula eqinileyo evela kulwelo ibizwa ngokuba yi-agglomeration (i-agglomeration, deposition), eveliswa ngokubanzi xa kupholiswa okanye kugxininiswe kwisisombululo, kwaye ukugquma kwe-electrophoretic kuxhomekeke kumbane. Kwi-cathodic electrophoretic coating, i-particle ene-positive charge aggregate kwi-cathode, kunye ne-charged particles (okt ion) aggregate kwi-anode. Xa amasuntswana e-colloidal (i-resin kunye ne-pigment) ehlanjululwe kakuhle (i-resin kunye ne-pigment) ifikelela kwi-cathode (i-substrate) Emva kommandla ongaphezulu (umgangatho ophezulu we-alkaline interface), ii-electron zifunyenwe kwaye ziphendule ngee-ion ze-hydroxide ukuba zibe yizinto ezingaxutywanga ngamanzi, ezifakwe kwi-cathode. ipeyintiwe workpiece).

Electrolysis

Kwisisombululo kunye ne-ionic conductivity, i-anode kunye ne-cathode ixhunywe kwi-current ngqo, i-anion itsalwa kwi-anode, kwaye i-cations itsalwa kwi-cathode, kwaye i-chemical reaction iyenzeka. I-anode ivelisa ukuchithwa kwesinyithi kunye ne-electrolytic oxidation ukuvelisa i-oksijini, i-chlorine, njl. I-anode yi-electrode enokuvelisa i-oxidation reaction. Isinyithi sichithwa kwi-cathode kwaye i-H + iyancipha i-electrolytically ibe yi-hydrogen.

I-Electroosmosis

Emva kokuba iziphelo ezimbini (i-cathode kunye ne-anode) yezisombululo ezinogxininiso oluhlukeneyo olwahlulwe yi-membrane ye-semipermeable zinamandla, into yokuba isisombululo esisezantsi sishukuthela kwicala eliphezulu lokuxilwanisa libizwa ngokuba yi-electroosmosis. Ifilimu yokugquma ifakwe nje kumphezulu wento egqunyiweyo yifilimu enesiqingatha. Ngaphantsi kwesenzo esiqhubekayo sentsimi yombane, amanzi aqulethwe kwi-dialysis yefilimu yokugcoba ngaphandle kwefilimu kwaye ihambela kwindawo yokuhlamba ukuze ikhuphe ifilimu. Le yi-electroosmosis. I-Electroosmosis ijika ifilimu yokugquma i-hydrophilic ibe yifilimu yokugquma i-hydrophobic, kwaye ukuphelelwa ngamanzi emzimbeni kwenza ifilimu yokwambathisa ixinene. Ipeyinti emanzi emva kokuqubha ngepeyinti efanelekileyo ye-electro-osmosis electrophoretic inokuchukumiseka kwaye ingabambeki. Ungalususa ulwelo lokuhlambela ngokubambelela kwifilim yepeyinti emanzi ngamanzi.

Iimpawu ze-Electrocoating

Ifilimu yepeyinti ye-Electrophoretic ineenzuzo zokugcwala, ukufana, ukunyanzeliswa kunye nokugubungela okugudileyo. Ukuqina, ukunamathela, ukuxhathisa ukubola, ukusebenza kwempembelelo, kunye nokunyanzeliswa kwefilimu yepeyinti ye-electrophoretic kungcono kakhulu kunezinye iinkqubo zokugquma.

(1) Ipeyinti enyibilikayo yamanzi isetyenzisiweyo, amanzi asetyenziswa njengendlela yokunyibilika, egcina i-solvents eninzi yezinto eziphilayo, inciphisa kakhulu ukungcoliseka komoya kunye nobungozi bokusingqongileyo, ikhuselekile kwaye icocekile, kwaye iphephe ingozi efihliweyo yomlilo;

(2) Ukusebenza kwepeyinti kuphezulu, ilahleko yepeyinti incinci, kwaye izinga lokusetyenziswa kwepeyinti linokufikelela kwi-90% ukuya kwi-95%;

3 Inxalenye nganye ye-workpiece, efana ne-inner layer, i-depressions, i-welds, njl., inokufumana ifilimu yokugqoka iyunifomu kunye ne-smooth, eyisombulula ingxaki yezinye iindlela zokugubungela kwii-workpieces ezinobunzima. Ingxaki yokupeyinta;

(4) Ukusebenza kwemveliso kuphezulu, kwaye ukwakhiwa kunokuqonda imveliso ezenzekelayo kunye neqhubekayo, ephucula kakhulu ukusebenza kakuhle;

(5) Isixhobo sintsokothile, ixabiso lotyalo-mali liphezulu, ukusetyenziswa kwamandla kukhulu, ubushushu obufunekayo ekomisweni nasekunyangelweni buphezulu, ulawulo lwepeyinti nokupeyinta luntsonkothile, iimeko zokwakha zingqongqo, kwaye ukucocwa kwamanzi amdaka kuyafuneka. ;

(6) Kuphela yipeyinti enyibilikayo emanzini enokusetyenziswa, kwaye umbala awunakuguqulwa ngexesha lokwaleka. Ukuzinza kwepeyinti akulula ukulawula emva kokugcinwa ixesha elide.

(7) Isixhobo sokugquma i-electrophoretic sinzima kwaye umxholo weteknoloji uphezulu, ofanelekileyo ukuveliswa kombala osisigxina.

Unyino lwe-Electrocoating

(1) Ilungele kuphela ukugquma kwe-primer ye-conductive substrates efana neendawo zoomatshini besinyithi esinentsimbi kunye neentsimbi ezingenayo i-ferrous. Izinto ezingaqhubekiyo ezifana neenkuni, iplastiki, ilaphu, njl njl. azinakugqunywa ngale ndlela.

(2) Inkqubo yokugqoka i-Electrophoretic ayifanelekanga kwizinto ezigqunyiweyo ezenziwe ngeentsimbi ezininzi, ukuba iimpawu ze-electrophoresis zihlukile.

(3) Inkqubo yokugqoka i-Electrophoretic ayinakusetyenziselwa izinto ezifihliweyo ezingenakumelana nokushisa okuphezulu.

(4) I-electrophoretic coating ayifanelekanga ukugquma ngeemfuno ezilinganiselweyo kumbala. Ukufakwa kwe-Electrophoretic yemibala eyahlukeneyo kufuneka kupeyintwe kwiigrooves ezahlukeneyo.

(5) Ukugquma kwe-Electrophoretic akukhuthazwa kwimveliso ye-batch encinci (ixesha lokuhlaziywa kwebhafu lingaphezulu kweenyanga ezi-6), kuba isantya sokuhlaziya ibhafu sicotha kakhulu, i-resin ebhafini iyaguga kwaye umxholo we-solvent uyatshintsha. kakhulu. Ibhafu ayizinzanga.

Amanyathelo e-Electrocoating

(1) Ngokwalekwa kwe-electrophoretic yemigangatho yesinyithi ngokubanzi, ukuhamba kwenkqubo kuku: ukucocwa kwangaphambili → ukuthoba igrisi → ukuhlamba amanzi → ukususwa komhlwa → ukuhlamba amanzi → ukungathathi hlangothi → ukuhlamba amanzi → ukuhlamba amanzi → ukuhlamba amanzi → ukudlula → i-electrophoretic coating → itanki yokucoca → ukuhlanjwa kwamanzi nge-ultrafiltration → ukomisa → ngaphandle kweintanethi.

(2) I-substrate kunye ne-pretreatment yento edibeneyo inempembelelo enkulu kwifilimu yokugqoka i-electrophoretic. Ukuchithwa kwesinyithi ngokuqhelekileyo kuchithwa ngokuqhunyiswa kwesanti okanye ukudutyulwa, umsonto womqhaphu usetyenziselwa ukususa uthuli oludadayo kumphezulu wesixhobo sokusebenza, kwaye i-sandpaper isetyenziselwa ukususa izithonga zentsimbi ezishiyekileyo kunye nobunye ubumdaka phezu komhlaba. Umphezulu wensimbi uphathwa ngokukhupha kunye nokususwa kwe-rust. Xa iimfuno zomphezulu ziphezulu kakhulu, i-phosphating kunye ne-passivation surface treatment ziyafuneka. Izixhobo zokusebenza zetsimbi zentsimbi kufuneka zibe ne-phosphated phambi kwe-anodic electrophoresis, ngaphandle koko ukuxhathisa kwe-corrosion yefilimu yepeyinti kuya kuba nzima. Kunyango lwe-phosphating, ifilimu ye-zinc yetyuwa ye-phosphating ikhethwa ngokuqhelekileyo, kunye nobukhulu obumalunga ne-1 ukuya kwi-2 μm, kwaye ifilimu ye-phosphate iyadingeka ukuba ibe neekristale ezintle kunye ezifanayo.

(3) Kwinkqubo yokucoca, ukuhluzwa okuphambili kuyamkelwa ngokubanzi, kwaye isihluzo sisakhiwo sengxowa yemesh. Ipeyinti ye-electrophoretic ithuthelwa kwisihluzo ngepompo ethe nkqo yokuhluza. Ukuqwalasela umjikelezo obanzi wokutshintshwa kunye nomgangatho wefilimu yepeyinti, isikhwama sokucoca kunye nobukhulu bepore ye-50μm iyona nto ingcono. Ayinakuhlangabezana kuphela neemfuno zomgangatho wefilimu yepeyinti, kodwa iphinde isombulule ingxaki yokuvala isikhwama sokucoca.

(4) Ubungakanani benkqubo yokujikeleza kwe-electrophoretic coating ichaphazela ngokuthe ngqo ukuzinza kwebhafu kunye nomgangatho wefilimu yepeyinti. Ukwandisa umthamo wokujikeleza kunciphisa imvula kunye namaqamza olwelo lokuhlambela; nangona kunjalo, ukuguga kwamanzi okuhlamba kuyakhawuleza, ukusetyenziswa kwamandla kuyanda, kwaye ukuzinza kolwelo lokuhlambela kuba kubi. Kukulungele ukulawula amaxesha omjikelezo we-tank liquid ukuya kwi-6-8 amaxesha / h, engaqinisekisi kuphela umgangatho wefilimu yepeyinti, kodwa iqinisekisa nokusebenza okuzinzile kwetanki yamanzi.

(5) Njengoko ixesha lokuvelisa lisanda, ukunyanzeliswa kwe-anode diaphragm kuya kwanda kwaye i-voltage esebenzayo esebenzayo iya kuncipha. Ke ngoko, kwimveliso, umbane osebenzayo wobonelelo lwamandla kufuneka unyuswe ngokuthe ngcembe ngokwelahleko yombane ukuze ubuyekeze ukuhla kombane we-anode diaphragm.

(6) Inkqubo yokucoca i-ultrafiltration ilawula ukuxinwa kwee-ion zokungcola eziziswa yi-workpiece ukuqinisekisa umgangatho wokugquma. Ekusebenzeni kwale nkqubo, kufuneka kuqatshelwe ukuba xa inkqubo isebenza, kufuneka iqhube ngokuqhubekayo kwaye inqatshelwe ngokungqongqo ukuba iqhube ngokukhawuleza ukukhusela i-membrane ye-ultrafiltration ukuba yome. I-resin eyomileyo kunye ne-pigment ibambelela kwi-membrane ye-ultrafiltration kwaye ayikwazi ukucocwa ngokucokisekileyo, eya kuchaphazela kakhulu ukunyanzeliswa kwamanzi kunye nobomi benkonzo ye-membrane ye-ultrafiltration. Umlinganiselo wokuphuma kwamanzi we-membrane ye-ultrafiltration ibonisa ukuhla okuhla kunye nexesha lokuhamba. Kufuneka icocwe kube kanye ngeentsuku ezingama-30-40 zomsebenzi oqhubekayo ukuze kuqinisekiswe ukuba amanzi e-ultrafiltration afunekayo kwi-ultrafiltration leaching kunye nokuhlamba.

(7) Indlela yokugqoka i-electrophoretic ifanelekile kwinkqubo yokuvelisa inani elikhulu lemigca yendibano. Umjikelezo wokuhlaziywa kwebhafu ye-electrophoresis kufuneka ube phakathi kweenyanga ezi-3. Ulawulo lwezenzululwazi lokuhlambela lubaluleke kakhulu. Iiparamitha ezahlukeneyo zokuhlambela zivavanywa rhoqo, kwaye ibhafu iyalungiswa kwaye ithathelwe indawo ngokweziphumo zovavanyo. Ngokuqhelekileyo, iiparamitha zesisombululo sokuhlambela zilinganiswa ngokuphindaphindiweyo: ixabiso le-pH, umxholo oqinileyo kunye ne-conductivity yesisombululo se-electrophoresis, isisombululo se-ultrafiltration kunye nesisombululo sokucoca i-ultrafiltration, i-anion (anode) isisombululo se-polar, i-lotion ejikelezayo, kunye nesisombululo sokucoca i-deionization kanye. Usuku; Umlinganiselo wesiseko, umxholo we-organic solvent, kunye nelebhu yovavanyo lwetanki encinci kabini ngeveki.

8 izikhombisi ezifana nokubambelela kunye nokuxhathisa ukubola kwefilimu yokugqoka. Umjikelo wokuhlola uhambelana nemigangatho yokuhlola umenzi, kwaye ngokubanzi ibhetshi nganye kufuneka ihlolwe.

Unyango Lwendalo Phambi Kwe-Electrophoresis

Ukunyangwa komphezulu we-workpiece ngaphambi kokugquma yinxalenye ebalulekileyo yokwaleka kwe-electrophoretic, ikakhulu ibandakanya ukucolwa, ukususwa komhlwa, ukumiswa komphezulu, i-phosphating kunye nezinye iinkqubo. Umgangatho wonyango lwayo awuchaphazeli nje ukubonakala kwefilimu, unciphisa ukusebenza kwe-anti-corrosion, kodwa utshabalalisa ukuzinza kwesisombululo sepende. Ngoko ke, kumphezulu we-workpiece ngaphambi kokupeyinta, kuyafuneka ukuba ungabikho kwi-oyile ye-oyile, amanqaku e-rust, akukho khemikhali yangaphambi kokunyanga kunye ne-phosphating sedimentation, njl., kwaye ifilimu ye-phosphating ineekristale ezixineneyo kunye ezifanayo. Ngokubhekiselele kwiinkqubo ezahlukeneyo zonyango lwangaphambili, asiyi kuxoxa ngazo ngabanye, kodwa sibeka phambili amanqaku ambalwa okuqwalaselwa:

I-1) Ukuba i-degreasing kunye ne-rust ayihlambulukanga, ayiyi kuchaphazela kuphela ukubunjwa kwefilimu ye-phosphating, kodwa iphinde ithintele amandla okudibanisa, ukusebenza kokuhlobisa kunye nokuchasana kwe-corrosion ye-coating. Ifilimu yepeyinti ixhomekeke kwi-shrinkage kunye ne-pinholes.

I-2) I-Phosphating: Injongo kukuphucula ukunamathela kunye nekhono lokuchasana ne-corrosion yefilimu ye-electrophoretic. Indima yayo imi ngolu hlobo lulandelayo:

(1) Ngenxa yempembelelo yenyama kunye neekhemikhali, ukunamathela kwefilimu ye-organic coating kwi-substrate kuphuculwe.

(2) Ifilimu ye-phosphating iguqula umphezulu wesinyithi ukusuka kwi-conductor elungileyo ukuya kwi-conductor engalunganga, ngaloo ndlela inqanda ukubunjwa kweebhetri ezincinci kumphezulu wesinyithi, ukuthintela ngokufanelekileyo ukubola kwengubo, kunye nokwandisa ukuxhathisa ukubola kunye nokuxhathisa kwamanzi ukutyabeka. Ukongezelela, kuphela ngesiseko sokunciphisa ngokucokisekileyo kunye nokunciphisa, ifilimu eyanelisayo ye-phosphating inokuqulunqwa kwindawo ecocekileyo, iyunifomu, kunye negrisi. Ukusuka kulo mba, ifilimu ye-phosphating ngokwayo iyona nto ibonakalayo kwaye inokwethenjelwa yokuzihlola kwisiphumo senkqubo yonyango lwangaphambili.

I-3) Ukuhlamba: Umgangatho wokuhlamba kwinqanaba ngalinye le-pretreatment liya kuba nefuthe elikhulu kumgangatho we-pretreatment yonke kunye nefilimu yepeyinti. Ukucocwa kokugqibela kwamanzi okuhlanjululwayo ngaphambi kokupeyinta, qiniseka ukuba i-conductivity ethontsizayo yento egqunyiweyo ayikho ngaphezu kwe-30μs / cm. Ukucoca akucocekanga, njengesixhobo sokusebenza:

(1) Iasidi eyintsalela, ulwelo lwekhemikhali ephosphating, ukushukuma kweresin kulwelo lwepeyinti, kunye nokuwohloka kozinzo;

(2) Izinto ezishiyekileyo zangaphandle (i-oil stains, uthuli), imingxuma eyanciphayo, amaqhekeza kunye nezinye iziphene kwifilimu yepeyinti;

(3) I-electrolyte eshiyekileyo kunye neetyuwa zikhokelela ekwandiseni ukusabela kwe-electrolysis kunye nokuvelisa i-pinholes kunye nezinye izifo.

Ixesha lokuposa: Apr-17-2021