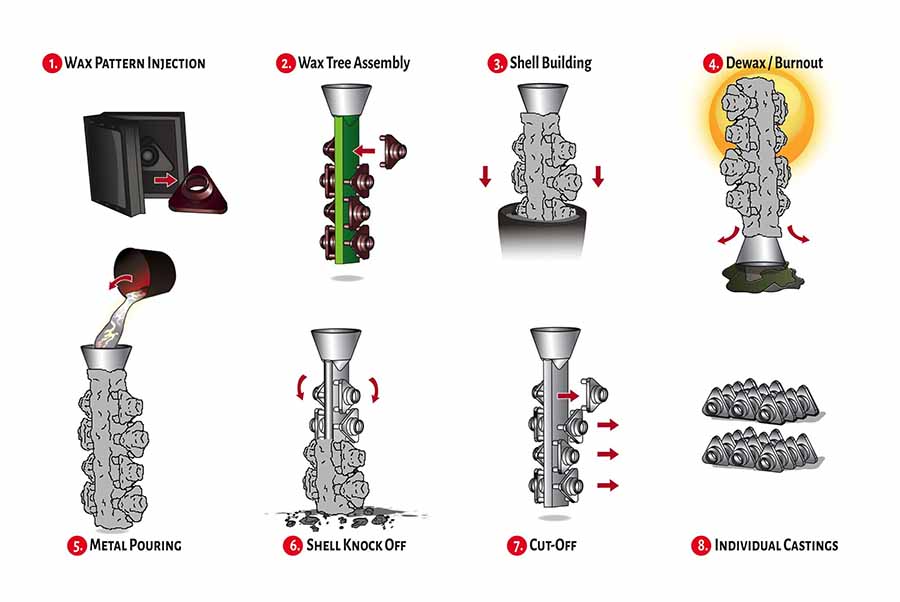

Ukusatshalaliswa kotyalo-maliisebenzisa iipateni zewax eziveliswa zizixhobo ezizodwa nezikhethekileyo ngokwezinto ezifunwayo. Iipateni ze-wax (i-replicas) zijikelezwe ngamaleko ezinto eziqhankqalazayo ezidibeneyo ukuze zenze iqokobhe elomeleleyo lokumelana nesinyithi esinyibilikisiweyo esishushu kunye ne-alloys. Inkqubo ye-wax iyakususa i-wax ukuvumela umngxuma ovulekileyo ukuze isinyithi esinyibilikisiweyo sizalise ukuze zenze iindawo zokuphosa ezifunwayo. Yiyo loo nto utyalo-mali lukwabizwa ngokuba yinkqubo yokulahla i-wax elahlekileyo. Kwisiseko sotyalo-mali lwangoku, izinto ezibotshiweyo zibhekisa ikakhulu kwi-silica sol kunye neglasi yamanzi, enokuqinisekisa ukuba umphezulu ococekileyoutyalo mali. Inkqubo yokuphosa utyalo-mali isoloko isetyenziselwa ukuvelisa i-carbon steel castings, i-alloy steel castings,iicasts steel stainlesskunye nezinto ezenziwe ngobhedu. Apha kweli nqaku, sizama ukwazisa amanyathelo aphambili otyalo-mali.

Phuhlisa iSixhobo sokutofa iWax

Ngokwezinto ezinqwenelekayo zokusa kunye nokuqwalasela isibonelelo se-post-machining kunye nokuncipha okunokwenzeka, iinjineli kwi-investment casting Foundry kufuneka ziyile kwaye zivelise ukungunda kwintsimbi (ekwabizwa ngokuba yi "die") kunye nezixhobo zokuvelisa iipateni ze-wax.

Ukudala ipateni yeWax

Kwixesha langokuisiseko sokugalela ngewax esilahlekileyo, iipateni ze-wax ngokuqhelekileyo zenziwe ngokufaka i-wax kwisixhobo sesinyithi okanye "ifa" ngoomatshini abakhethekileyo bokutofa. Ukuphoswa okuninzi, isixhobo se-silicon sihlala senziwe kumfanekiso oqingqiweyo womzobi kwaye i-wax iyatofwa okanye igalelwe kumgodi osisiphumo.

Indibano yoMthi weWax

Ngokuqhelekileyo akunamali ukwenza iinxalenye ezincinci enye ngexesha, ngoko ke iipateni ze-wax zihlala zifakwe kwi-wax sprue. Umthwebeba ophakathi kwepateni kunye nesprue zibizwa ngokuba ngamasango, ngenxa yokuba ziginya isalathiso kunye nokuhamba kwe-alloy etyhidiweyo kwisithuba esenziwe yipateni. Isprue isebenza ngeenjongo ezimbini

- 1. Ibonelela ngomphezulu onyukayo wokuhlanganisa iipateni ezininzi zibe ngumbumba omnye, oya kuthi kamva uzaliswe ngealloyi.

- 2. Ibonelela ngendlela yokuhamba yealloyi etyhidiweyo kwisithuba esidalwe ziipateni zewax.

Isakhiwo seShell

Inyathelo elilandelayo kwinkqubo kukwakha iqokobhe le-ceramic elijikeleze umthi we-wax. Eli qokobhe liya kuba sisingundo ekugalelwa kuso isinyithi. Ukwakha igobolondo, umthi ufakwe kwisitya se-ceramic okanye i-slurry. Emva kokuntywila, isanti entle okanye isetyenziswe kwindawo emanzi. Umngundo uvumelekile ukuba wome, kwaye inkqubo iphinda iphindwe kaninzi de kube ngumbumba we-ceramic owenziweyo, okwaziyo ukumelana noxinzelelo lwentsimbi etyhidiweyo kunye ne-alloys ngexesha lokugalela.

Idewax / Ukutshiswa

Ngaphambi kokuthululela isinyithi kwi-mold, i-wax isuswa ngokufudumeza igobolondo. Oku kwenziwa ngokwesiqhelo kwi-autoclave yomphunga, efana nesikhululo soxinzelelo lweshishini. Enye indlela kukusetyenziswa kwe-oven ye-flash fire, enyibilikayo kwaye itshisa i-wax. Iwax inokuqokelelwa iphinde isetyenziswe ukwenza iipateni ezilandelayo zewax. Uninzi lwabaseki botyalo-mali basebenzisa zombini iindlela kwikonsathi. Umlilo odanyazayo utshisa iwax eyintsalela kwaye unyange iqokobhe, lilungele ukufumana isinyithi esityhidiweyo kunye nealloys.

Ukugalelwa kwesinyithi

Ngaphambi kokuba isinyithi sigalelwe kwi-ceramic mold okanye igobolondo, i-mold ifudumala kwiqondo lokushisa elithile ukukhusela i-alloy etyhidiweyo ekuqinisweni okanye ekhenkceni ngaphambi kokuba i-mold izaliswe. I-alloy inyibilika kwikomityi ye-ceramic (ebizwa ngokuba yi-crucible) isebenzisa inkqubo eyaziwa ngokuba yi-induction melting. Umsinga wombane ohamba rhoqo udala umhlaba wemagnethi ojikeleze ialloy, uvelisa amasimi ombane ngaphakathi kwentsimbi (eddy currents). Imisinga yeeddy ifudumeza i-alloy ngenxa yokumelana nombane. Xa i-alloy ifikelela kwiqondo lokushisa elichaziweyo, ithululelwa kwi-mold, kwaye isikhunta sivunyelwe ukupholisa.

Shell Knock Off

Yakuba ipholile, imathiriyeli yeqokobhe iyasuswa kwintsimbi kusetyenziswa iindlela zoomatshini ezifana nehamile, ukuqhushumba kwamanzi ngoxinzelelo oluphezulu okanye itafile yokungcangcazela. Ukususwa kweShell kunokufezekiswa ngeekhemikhali, kusetyenziswa isisombululo esivuthayo se-caustic okanye i-potassium hydroxide okanye i-sodium hydroxide, kodwa le ndlela ikhutshwe ngenxa yokukhathazeka kokusingqongileyo kunye nempilo.

Yisuse ecaleni

Nje ukuba imathiriyeli yeqokobhe isusiwe, i-sprue kunye namasango zisikwa ngesandla okanye ngesarha ye-chop, ukusika i-laser yetotshi. Iindawo zokusika kufuneka zigaywe kwindawo entle.

Umntu ngamnye

Emva kokuba iinxalenye zisuswe kwi-sprue, kunye namasango asusiwe, umphezulu unokugqitywa ngeendlela ezininzi ezifana ne-vibratory, i-media finishing, i-belting, i-hand grinding, i-polish. Ukugqiba kunokwenziwa ngesandla, kodwa kwiimeko ezininzi kuzenzekelayo.Iindawo zokuphosaemva koko ziyahlolwa, zimakishwe (ukuba ziyafuneka), zipakishwe kwaye zithunyelwe. Ngokuxhomekeke kwisicelo, iinxalenye zokuphosa utyalo-mali zingasetyenziselwa "kwimilo yenetha" yazo okanye zidluleumatshinikwimigangatho echanekileyo.

Ixesha lokuposa: Jan-18-2021