Ukuphosa ngokuchanekileyo kukwabizwa ngokubautyalo mali. Le nkqubo yokuphosa iyancipha okanye ayisiki ngexesha lenkqubo yokuphosa. Yindlela yokuphosa enoluhlu olubanzi lwezicelo, ukuchaneka okuphezulu komgangatho wokusa, kunye nomgangatho obalaseleyo womphezulu. Akukho kwiimeko zokushisa eziphezulu, kwaye zifaneleke ngakumbi kumacandelo okuphosa kumashishini achanekileyo afana ne-aerospace kunye nokukhusela ilizwe. Yayiyeyokuqala ukusebenzisa indlela yentsimbi echanekileyo yokugalela ukuphosa iiblade zeinjini yomoya kwi-injini yayo ehamba emoyeni ngelo xesha. Imveliso egqityiweyo yanconywa yizo zonke iinkalo, kwaye le ndlela yakhuthazwa ngokubanzi. Insimbi engenastainless ukujula ngokuchaneka kwetekhnoloji kwishishini le-Foundry, kodwa yahlukile kushishino lwesiseko semveli kuba ixabiso elongezelelweyoiimveliso zokuphosa ngokuchanekileyoiphezulu.

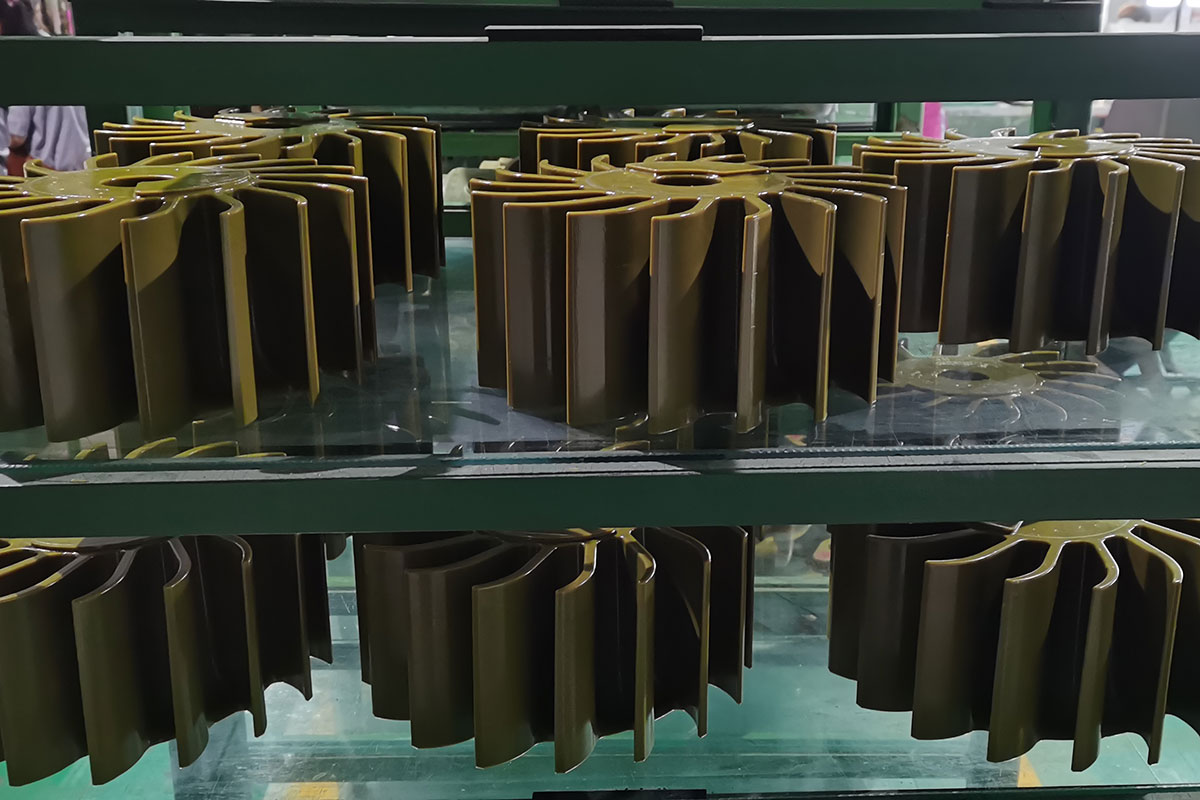

Inkqubo yeSilica Sol Shell

Inkqubo yokwenza iqokobhe le-silica sol idla ngokusetyenziswa kushishino oluphucukileyo lwangaphakathi lwenjini yokutshisa. Ingubo esetyenziswe kule ndlela inozinzo olungcono, ayifuni inkqubo yokuqina kweekhemikhali, ichasene namaqondo okushisa aphezulu, kwaye inokuchasana okungcono kwi-deformation. Nangona kunjalo, obu buchwepheshe bunayo le ntsilelo ethile, oko kukuthi, ukufudumala kwe-wax mold kuncinci, okunokuphuculwa ngokudibanisa i-surfactants, kodwa kuya kwandisa utyalo-mali ukuya kwinqanaba elithile.

Inkqubo ye-Shell yeglasi yamanzi

Le ndlela yaqanjwa kwangethuba. Ilizwe lethu lazisa obu buchwepheshe buvela eSoviet Union ngeminyaka yoo-1950 kunye noo-1960. Le ndlela ineendleko eziphantsi, ukusebenza okulula, kunye neemfuno ezisezantsi zemathiriyeli. Iimpawu ezisisiseko zenkqubo zisebenzisa iparafini-stearic acid ephantsi-ubushushu bezinto zokungunda, kwaye i-binder kwinkqubo yokwenza iqokobhe isebenzisa iglasi yamanzi, esetyenziswa ngokubanzi kwintsimbi echanekileyo yokuphosa. Nangona kunjalo, eyona ngxaki inkulu yale ndlela xa kuthelekiswa nenkqubo yokwenza iqokobhe le-silica sol kukuba umgangatho womphezulu wezinto ezifunyenweyo zingumndilili kwaye ukuchaneka kwedimensional kuphantsi. Ukusukela ekuqalisweni kobu buchwepheshe, uphuculo olukhulu lwenziwe, ikakhulu kule miba ilandelayo:

1. Phucula iqokobhe lokwaleka.

Olona phuculo luphambili kukongeza inani elithile lodongwe oluchasayo kumqolo weqokobhe, ophucula kakhulu amandla eqokobhe, kwaye iqonde iqokobhe elinye lokugcada kunye nokudubula.

2. Ukuphuculwa kwe-hardener.

I-hardener yendabuko isebenzisa i-ammonium chloride, kodwa le nto iya kukhupha isixa esikhulu se-ammonia kunye negesi ye-nitrogen oxide ngexesha lenkqubo yokuphosa, eya kungcolisa umoya. Ngoko ke, isisombululo se-aluminium chloride sisetyenziselwa endaweni, kwaye i-aluminium chloride crystal isetyenziswa ngakumbi. Umphumo we-agent ufana ne-ammonium chloride, kodwa kwiminyaka yakutshanje, ukusetyenziswa kwe-magnesium chloride hardener kunenzuzo enkulu ngokwemiqathango yokuqina kwesantya kunye nentsalela, ngoko ngoku kuthambekele ngakumbi ekusebenziseni i-magnesium chloride njenge-hardener. .

3. Iqokobhe elihlanganisiweyo.

Ngenxa yokuba umgangatho womphezulu weqokobhe leglasi yamanzi ineziphene ezithile, iindawo ezininzi zangaphambili zifakwe ngendlela yokuphosa i-multi-layer mold composite casting, egcina iindleko kwelinye icala kwaye iphucula umgangatho wokuphosa kwelinye. isandla.

4. Ukuphuhliswa kobuchwepheshe obutsha.

Okwangoku, iinkqubo ezintsha ezivuthiweyo kufuneka zibe yinkqubo yokugalela i-self-priming, ukungunda kweplastiki yogwebu, ukubunjwa kweqokobhe elityhidiweyo kunye nezinye iinkqubo. Ezi nkqubo zineenzuzo eziphambili kwezinye iinkalo, kodwa uphuculo lwexesha elizayo luya kutsala abasebenzi bezenzululwazi kunye nezobuchwepheshe.

Ukusetyenziswa kweTekhnoloji eNxulumeneyo kunye neTekhnoloji yePrototyping eKhawulezayo

Uyilo kunye nokuveliswa kwe-mold kwinkqubo yokwenza i-wax echanekileyo yokuphosa i-wax molds iyinkimbinkimbi kwaye ichitha ixesha, kodwa iteknoloji ye-prototyping ngokukhawuleza inokwenza le ntsilelo. Itekhnoloji ye-prototyping ekhawulezayo yodwa ayinakuphunyezwa ngenxa yokulinganiselwa kwezinto eziphathekayo, abaninzi kwiminyaka yamuva Ukusetyenziswa kweteknoloji yepolymer ukufumana imilo ejikelezileyo yokuphosa, kwaye emva koko yenze i-wax mold, esetyenziselwa ukuphosa ngokuchaneka kwensimbi engenasici. Umzekelo, ukukhanya okuphilisa itekhnoloji yemodeli ye-three-dimensional (SLA) kunye ne-selective laser sintering technology (SLS). Ezi teknoloji zimbini okwangoku zithekhnoloji esele zikhulile zisetyenziswa ngokudityaniswa nokusatshalaliswa kotyalo-mali. Itekhnoloji ye-SLA inokubonelela ngokuchaneka okuphezulu komgangatho, ngakumbi kwiindawo. Ukuchaneka komphezulu wangaphandle, i-SLS, ukuya kuthi ga kumlinganiselo othile, izinto ezikrwada zinexabiso eliphantsi, kodwa ukuchaneka kukwanesithuba esithile xa kuthelekiswa nobuchwepheshe be-SLA, obulungele umsebenzi othile wokuphosa kunye neemfuno zeendleko. Nangona kunjalo, kusafuneka ukuba ubeke ingqalelo ekulawuleni indibaniselwano ephambili yetekhnoloji yeprototyping ekhawulezayo kunye netsimbi echanekileyo yokuphosa itekhnoloji ngexesha lokusetyenziswa, njengoqwalaselo olubanzi lolawulo lweendleko kunye nokuphosa ukuchaneka kwamalungu, kunye nokukhetha indawo efanelekileyo yokulinganisa itekhnoloji yeprototyping ekhawulezayo. kunye netekhnoloji yokuphosa imali. Umba ophambili wokudityaniswa kwezinto eziphilayo.

I-Multi-teknoloji iSetyenziso ngokunqamlezayo kunye neTekhnoloji yeKhompyutha

Uyilo lwesicwangciso kunye nomsebenzi wokuphucula kwinkqubo yokuphosa echanekileyo yensimbi engenasici ngumsebenzi odlayo kunye nochitha ixesha. Kwiminyaka yakutshanje, ngophuhliso oluqhubekayo lobuchwepheshe bekhompyuter, amashishini amaninzi afuna inani elikhulu lokubala kunye nokubala ngokuchanekileyo aye azisa umsebenzi wekhompyuter, kwaye ngokuhambelanayo kuye kwaphuhliswa iisoftware ezahlukeneyo zokubala, ezifana neProCAST, AutoCAD, AFSolid, Anycasting kunye nezinye iisoftware. . Ezi softwares zingabala okanye zifanise uyilo kunye nenkqubo yokuphosa yensimbi engenasici yokuphosa ngokuchanekileyo. Iskimu sokuphucula sangoku sinokulungiswa ngokubala kwedatha. Ukuphuhliswa kokulingisa kudlale indima entle ekukhuthazeni. Nangona kunjalo, kwinkqubo yangoku yokusetyenziswa, siye safumanisa ukuba kufuneka sinikele ingqalelo kwimodeli yokusetyenziswa kwesoftware yekhompyuter kunye neeparamitha ze-thermophysical zezinto ngokwazo. Isisombululo esihle kwezi ngxaki sinokunciphisa kakhulu ixesha lophuhliso lwensimbi engenasici.

Ixesha lokuposa: Oct-21-2021