Njengoko sisazi sonke, utyalo mali luvelisaiicastingsngokuchaneka okuchanekileyo kunye nokugqiba okulungileyo. Nangona kunjalo, ngexesha lenkqubo yokuvelisautyalo mali, zininzi iziphene zokuphosa eziqhelekileyo. Ngokusekelwe kumava ethu obunjineli kunye nezixhobo eziphambili, sinokufumana indlela yokuthintela iingxaki ezinjalo ngokuhlalutya oonobangela. Ngezantsi, sazisa iziphene ezininzi eziqhelekileyo zokuphosa kunye nezizathu zabo kunye neendlela zokuthintela. Ndiyathemba ukuba eli nqaku liluncedo kubathengi bethu ukuba baqonde iingxaki kunye nabalingane bethu, olu hlalutyo lunokukunceda uthintele iziphene zokuphosa.

Isithintelo esiphantsi kunye nesibanda

1. Inkcazo yengxaki:

I-undercasting ihlala ingenayo inyama kwindawo eludongeni olucekethekileyo lokuphosa okanye kude nomgijimi wangaphakathi, kwaye umgca wayo u-arc-shaped. Ukwahlula okubandayo kukuba imisonto emibini yesinyithi etyhidiweyo ayidityaniswanga ngokupheleleyo kwaye kukho amalungu acacileyo.

2. Unobangela:

1) Intsimbi ephantsi etyhidiweyo igalela ubushushu kunye nobushushu bokubumba

I-2) Isantya sokugalela sicotha okanye ukusetwa komgijimi akunangqiqo, ukuhamba kwentsimbi kude kakhulu

3) Ubunzima bodonga lokubunjwa buncinci kakhulu, kwaye ukuhamba kwesinyithi esinyibilikisiweyo kubi

4) Yinqumle ngexesha lokugalela

3. Amanyathelo othintelo:

1) Ukwandisa ubushushu besinyithi esinyibilikisiweyo kunye nobushushu bokubumba

2) Yandisa isantya sokugalela okanye ukwandisa inani okanye indawo yembaleki yangaphakathi ukunciphisa ukuhamba kwesinyithi esinyibilikisiweyo.

I-3) Yandisa intloko yoxinzelelo lwe-riser yokugalela ukukhusela ukunqunyulwa ngexesha lokugalela

Ukuncipha

1. Inkcazo yengxaki:

Inokufunyanwa kuphela ngokuhlolwa kweX-reyi. Ukucutheka komphezulu kunokufunyanwa ngokuhlolwa kwe-fluorescence okanye ukubola. Kwiimeko ezinzima, inokufumaneka emva kokuvuthela kwesanti.

2. Unobangela:

I-1) Isakhiwo sokuphosa singenangqiqo, kwaye iindawo ezishushu kakhulu okanye zikhulu kakhulu

2) Umthamo wobushushu wokunyuka okuthululwayo uncinci, osilelayo ukwenza ukuqina okulandelelanayo, okanye intloko yoxinzelelo incinci, enciphisa amandla okutya.

3) Iqondo lokushisa lokubumba liphantsi, izinga lokupholisa likhawuleza, kwaye umjelo wokutya uvaliwe

3. Amanyathelo othintelo:

I-1) Ukuphucula isakhiwo sokuphosa kunye nokunciphisa iindawo ezishushu

2) Seta isikhuphukeli ngokufanelekileyo, okanye ungeze ubambo lokutyisa olunokususwa ngeendlela zokucubungula, ukwandisa uxinzelelo lwentloko, ukuzeutyalo maliinokuqiniswa ngokulandelelana phantsi kwesenzo sentloko ethile yoxinzelelo

3) Yandisa ngokufanelekileyo iqondo lobushushu lokugalela kunye nobushushu bomngundo ukucothisa isantya sokupholisa

Ukuqhekeka okushushu

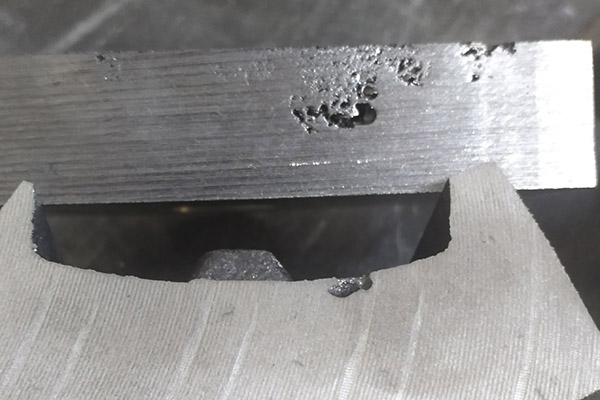

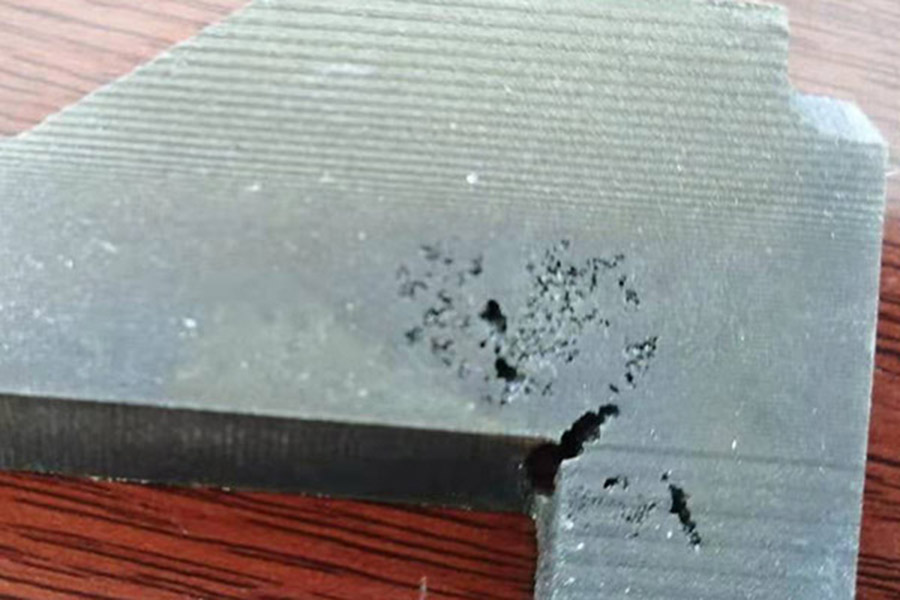

1. Inkcazo yengxaki:

Ukuqhekeka okungaqhelekanga kwe-intergranular ziveliswa kumphezulu okanye ngaphakathi, kwaye umphezulu we-oxidized. Inokubonwa emva kokucocwa kwesanti enzima, kwaye kuphela ukusetyenzwa kancinci okanye ukuhlolwa kokungena kungafunyanwa.

2. Oonobangela:

I-1) Inxulumene nokubunjwa kwe-alloy, umxholo wekhabhoni kunye ne-silicon uphezulu, uluhlu lobushushu besigaba solwelo-solid lukhulu, kwaye ukuqhekeka okushushu kulula.

I-2) Ubushushu obuphantsi bokubumba, ukubuyiswa okungahambi kakuhle kunye nesantya sokupholisa ngokukhawuleza

3) Ubunzima bokuphosa buhluka kakhulu, kwaye i-fillet yenguqu incinci kakhulu

3. Amanyathelo othintelo:

I-1) Kwii-alloys okanye iintsimbi ezithandwa kukuqhekeka okushushu, umxholo wekhabhoni kunye ne-silicon kufuneka ulawulwe ngokusemandleni ukuya kwimida ephakathi kunye nesezantsi.

2) Yandisa ubushushu bokubumba ngexesha lokugalela, nciphisa isantya sokupholisa, okanye unciphise amandla eqokobhe lokubumba.

I-3) Yongeza iimbambo zenkqubo yokuchasana nokuqhekeka kumalungu obunzima be-castings, okanye ukwandisa iifayili zenguqu.

Ukuqhekeka Okubandayo

Igama kunye neempawu:

Kukho iintanda eziqhubekayo ezigqobhozayo kwi-casting. Indawo emenyezelayo okanye indawo eneoksijini kancinane ibonakala kwindawo yokwaphuka.

Oonobangela

1. Ngethuba lenkqubo yokupholisa yokuphosa, i-shrinkage ithintekile, okubangelwa uxinzelelo lwe-thermal kunye noxinzelelo lokutshintsha kwesigaba, kwaye ezi zixinzelelo zidlula amandla ezinto eziphathekayo kwi-elastic state kwaye zibangele ukuphuka.

2. Kwinkqubo yokucoca igobolondo, ukusika isango, ukunyuka okanye ngexesha lokulungelelanisa, ukuphosa kunye noxinzelelo olushiyekileyo luxhomekeke kumandla angaphandle ukuze kubangele ukuphuka.

Iindlela Zokuthintela

1. Yongeza iimbambo eziqiniweyo kwiindawo ezibandayo ukuze uphucule ukubuyiswa kobume, ngaloo ndlela unciphisa ukuxhathisa kwe-shrinkage kunye nokuphosa uxinzelelo.

2. Kwinkqubo ye-post-casting, gwema impembelelo enzima phakathi kwe-castings.

Umngxuma wokuvuthela

Igama kunye neempawu

Kukho imingxuma ecacileyo okanye engabonakaliyo enomgangatho wangaphakathi ogudileyo kwi-casting.

Oonobangela

1. Ukungena komoya okungahambi kakuhle kwigobolondo lokungunda, okwenza kube mva kakhulu ukuba igesi engaphakathi ikhutshwe ngexesha lokugalela.

2. Ukudubula okungonelanga kobume begobolondo, okubangela ukukhutshwa okunganeleyo kweentsalela zezinto zokubumba kunye nezixhobo zokuvelisa igesi kwizinto zegobolondo.

3. Isiqulatho segesi yentsimbi siphezulu kakhulu, nto leyo ebangela ukuba i-deoxidation ingasebenzi kakuhle.

4. Ukumiselwa kwenkqubo yokugalela akunangqiqo, kubangela ukuba igesi yomntu ibandakanyeke ekugaleleni.

Iindlela Zokuthintela

1. Ukuphucula ukunyanzeliswa komoya kwigobolondo kwaye wongeze i-vents ukuba kuyimfuneko.

2. Iqokobhe elivulwe ngokupheleleyo.

3. Ukuphucula iindlela zokukhupha i-deoxidation.

4. Ukuphucula inkqubo yokungena.

Ukuphosa iPitting

Igama kunye neempawu

Kukho imingxuma eshinyeneyo efana namachaphaza kumphezulu wokusalwa.

Oonobangela

1. Xa i-ethyl silicate isetyenziswe njenge-binder, i-hydrolyzate engaphelelanga ikwinkqubo yokugubungela, umswakama ongaphakathi wangaphakathi uphantsi kakhulu, ukwenzela ukuba i-hydrolyzate ingakwazi ukuqhubela phambili i-hydrolyzed, kwaye "i-frost emhlophe" iyancipha emva kokutshisa.

2. Xa iglasi yamanzi isetyenziswa njengesibophelelo, ityuwa eshiyekileyo kwiqokobhe lokungunda idibana nesinyithi esinyibilikisiweyo yenze umngxuma.

3. Isinyithi esityhidiweyo sichithwa kakubi okanye i-slag ayicocwanga ngexesha lokubetha.

Iindlela zoThintelo:

1. Xa usebenzisa i-ethyl silicate njenge-binder, ngokufanelekileyo ukwandisa umthamo wamanzi ongeziweyo kunye nokwandisa umswakama ohambelanayo we-studio yepeyinti ukunciphisa i-hydrolysates engaphelelanga eseleyo.

2. Xa usebenzisa iglasi yamanzi njengesibophelelo, coca iqokobhe ngamanzi aneasidi emva kokukhutshwa kwewaxing.

3. Guqula i-coat surface ibe yi-silica sol njenge-binder.

4. Ngexesha lokunyibilikisa, qinisa i-deoxidation kunye nokususwa kwe-slag.

Ukuphosa iPinhole engaphantsi kwesikhumba

Igama kunye neempawu

Emva kokuba umphezulu wokubunjwa ukhazimlisiwe, amabala amancinci amnyama avela. Le nto iyenzeka kakhulu kwinickel-chromium istainless steel.

Oonobangela:

1. Izinto ezisetyenzisiweyo kakhulu zisetyenziswa ngexesha lesinyithi esinyibilikisiweyo, okanye izinto ezisetyenzisiweyo azizange ziphathwe kakuhle.

2. Ngethuba lenkqubo yokunyibilika, isinyithi esityhidiweyo si-oxidized okanye isinyithi esityhidiweyo sithatha i-gas, okubangela ukungabikho ngokwaneleyo kwe-deoxidation.

3. Isiqulatho sokungcola kwempahla yegobolondo iphezulu kakhulu, okanye i-agent edibeneyo kunye nentsimbi etyhidiweyo ine-chemical reaction.4. Ukusetwa ngokungekho ngqiqweni kwenkqubo yokungena.

Iindlela zoThintelo:

1. Lawula okanye unciphise ubungakanani bezinto ezisetyenzisiweyo, kwaye izinto ezisetyenzisiweyo kufuneka zisetyenziswe emva kokuvuthela kwesanti okanye ukudutyulwa kokudubula.

2. Lawula ngokungqongqo inkqubo yokunyibilikisa kwaye uqinise i-deoxidation.

3. Sebenzisa i-corundum edibeneyo, isanti ye-zircon kunye ne-silica sol okanye ipeyinti ye-ethyl silicate.

4. Zama ukusebenzisa isitofu esisezantsi sokugalela kunye nokwandisa imingxuma yokuphuma.

Isanti encangathi

Igama kunye neempawu

Kukho umaleko oncangathi wesanti kufutshane nembaleki okanye ngaphakathi kwendawo yokuphosa, kwaye kukho imingxunya ephakanyisiweyo okanye imingxuma emva kokuvuthuza kwesanti.

Oonobangela

1. Umxholo ongcolileyo we powder refractory esetyenziswe kwi-coating surface layer iphezulu kakhulu, kwaye ezi zinto zingcolileyo zisabela ngetsimbi etyhidiweyo ukuze zenze i-eutectic ephantsi yokunyibilika.

2. Ukushisa okuthululwayo kuphezulu kakhulu, ngokukodwa amabakala ensimbi aqukethe i-Al, Ti kunye nezinye izinto, ezibangela ukusabela kweekhemikhali phakathi kwesinyithi esityhidiweyo kunye ne-silica.

3. Ukumiswa kwenkqubo yokugawula akunangqiqo, kwaye ubuninzi bentsimbi etyhidiweyo buhamba ngomgijimi wangaphakathi, obangela ukushisa kwendawo.

Iindlela Zokuthintela

1. Sebenzisa i-jade yentsimbi edityanisiweyo okanye isanti ye-zircon endaweni yesanti yesilika, kwaye uzame ukungasebenzisi iglasi yamanzi njengesibophelelo.

2. Ukunciphisa ngokufanelekileyo iqondo lokushisa lokugalela.

3. Yongeza umgijimi wangaphakathi ukulungisa ibhalansi yobushushu kunye nokunciphisa ukushisa kwendawo.

I-Dilatant

Igama kunye neempawu

Ukuvuvukala kwendawo kwindiza enkulu yokuphosa, le nto ibonakala ngakumbi xa usebenzisa iglasi yamanzi njenge-binder.

Oonobangela

1. Isakhiwo sokuphosa singenangqiqo kwaye indawo yendiza inkulu kakhulu.

2. Igobolondo inamandla aphantsi kwiqondo lokushisa eliphezulu kwaye ayikwazi ukumelana noxinzelelo lwetsimbi etyhidiweyo.

Iindlela Zokuthintela

1. Ukuphucula isakhiwo, yongeza iimbambo zenkqubo okanye imingxuma yenkqubo kwindiza.

2. Xa usenza iqokobhe, sebenzisa izinto zegobolondo ezinobumdaka obuncinci kunye ne-refractoriness ephezulu, okanye ukwandisa ubukhulu beqokobhe.

I-Slag

Igama kunye neempawu

Kukho i-slag okanye enye i-debris ngaphakathi okanye umphezulu wokuphosa. Ukufakwa kwangaphakathi kufuneka kuchongwe nge-X-reyi okanye uhlolo lwemagnethi.

Oonobangela

1. Izinto ze-slag zincinci kakhulu kwaye azicocwa ngaphambi kokuba ucofe.

2. I-debris kwi-tapping trough ye-crucible ayizange ihlambuluke ngaphambi kokucofa kwaye yaziswa kwintsimbi etyhidiweyo.

3. Xa uphosa, ukugcinwa kwe-slag akulungile, kwaye i-slag ingena emgodini kunye nentsimbi etyhidiweyo.

Iindlela Zokuthintela

1. Lungisa ukubunjwa kwezinto ze-slag ngaphambi kokubetha ukunyusa i-viscosity yezinto ze-slag kwaye wenze kube lula ukususa i-slag.

2. Coca inkunkuma kumjelo ongaphambili wentsimbi ukunqanda ukuzisa ubumdaka kwintsimbi etyhidiweyo kwileyidi.

3. Ngaphambi kokutyhilwa, into etyhidiweyointsimbikufuneka ihlaliswe ngokufanelekileyo ukuququzelela i-slag edadayo.

4. Thatha i-teapot yokugalela i-ladle kunye ne-slag stopper okanye i-ceramic filter.

I-Decarburization

Igama kunye neempawu

Umxholo wekhabhoni womgangatho ophezulu we-casting ungaphantsi kune-matrix.

Oonobangela

1. Ngexesha lokuphosa, ukushisa kwentsimbi etyhidiweyo kunye nesikhunta siphezulu, kwaye izinga lokuqiniswa kwe-casting lihamba kancinci.

2. Ubunzulu boluhlu lwe-decarburization luhambelana nomoya wendawo yokupholisa yokuphosa. Okukhona uxinaniso lwemeko ye-oxidizing, kokukhona kubi kakhulu i-decarburization.

Iindlela Zokuthintela

1. Ukunciphisa ngokufanelekileyo ubushushu bokuphosa kunye nobushushu bokubumba ukukhawulezisa izinga lokupholisa.

2. Yenza ngokuzenzekelayo umoya wokunciphisa ujikeleze isikhunta, njengokongeza i-barium carbonate kunye ne-charcoal powder kwi-mold.

Ixesha lokuposa: Jan-22-2021