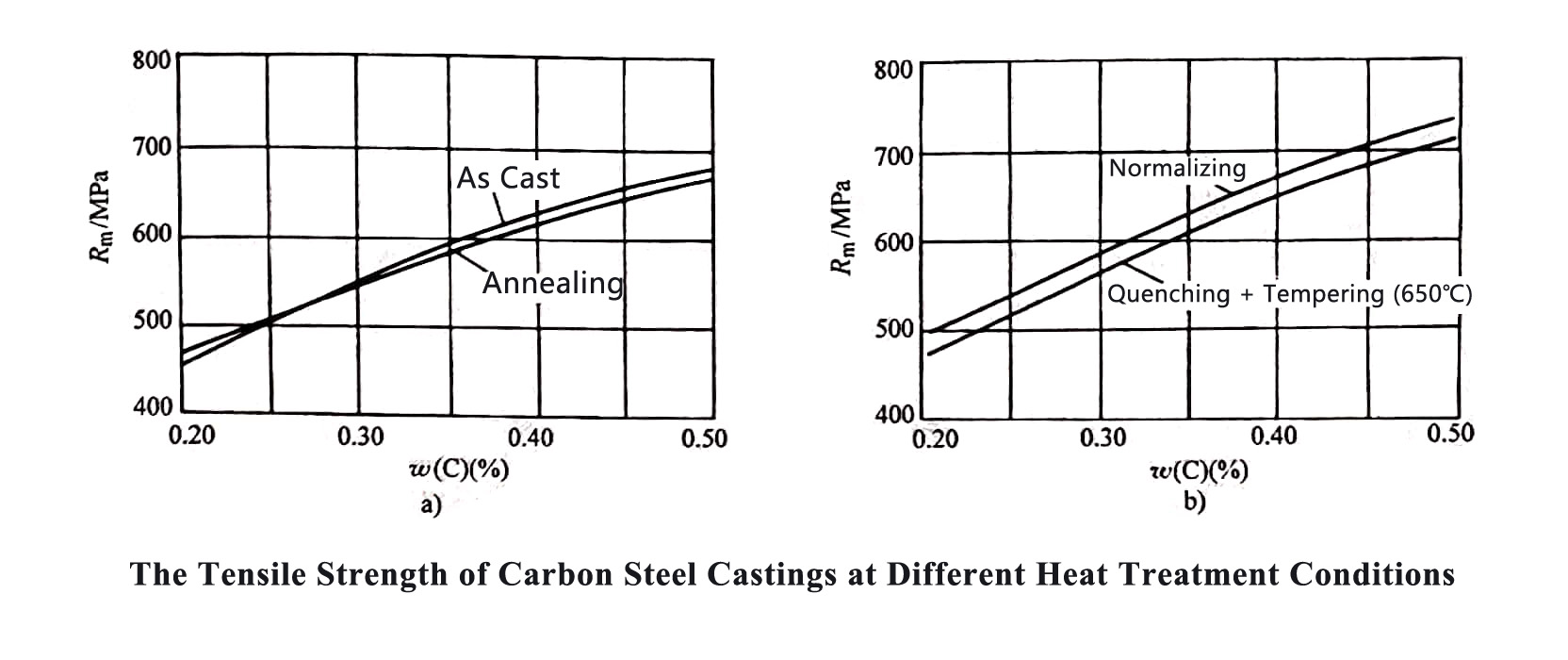

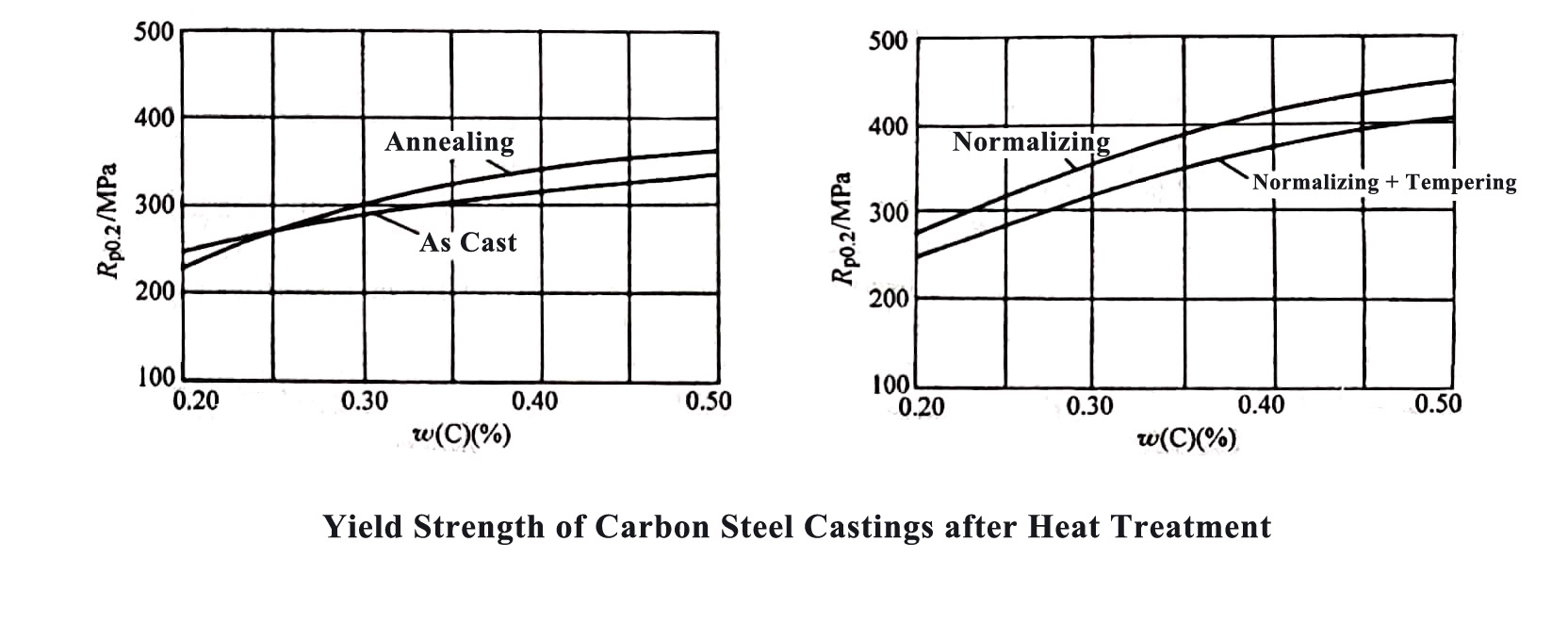

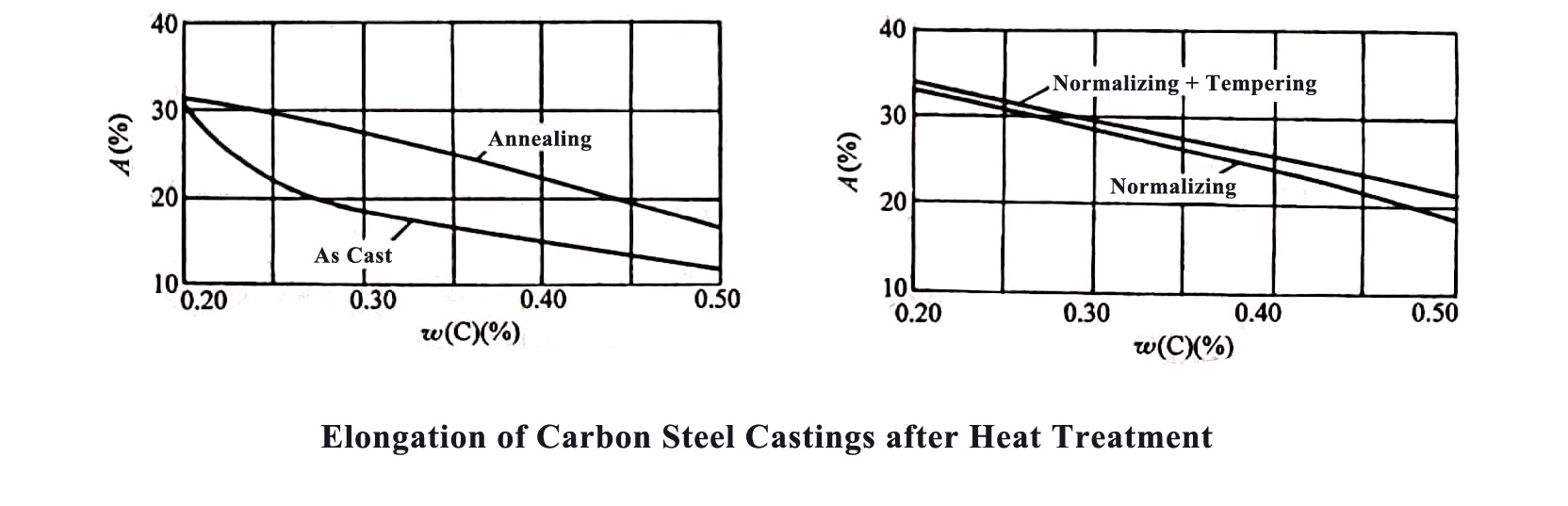

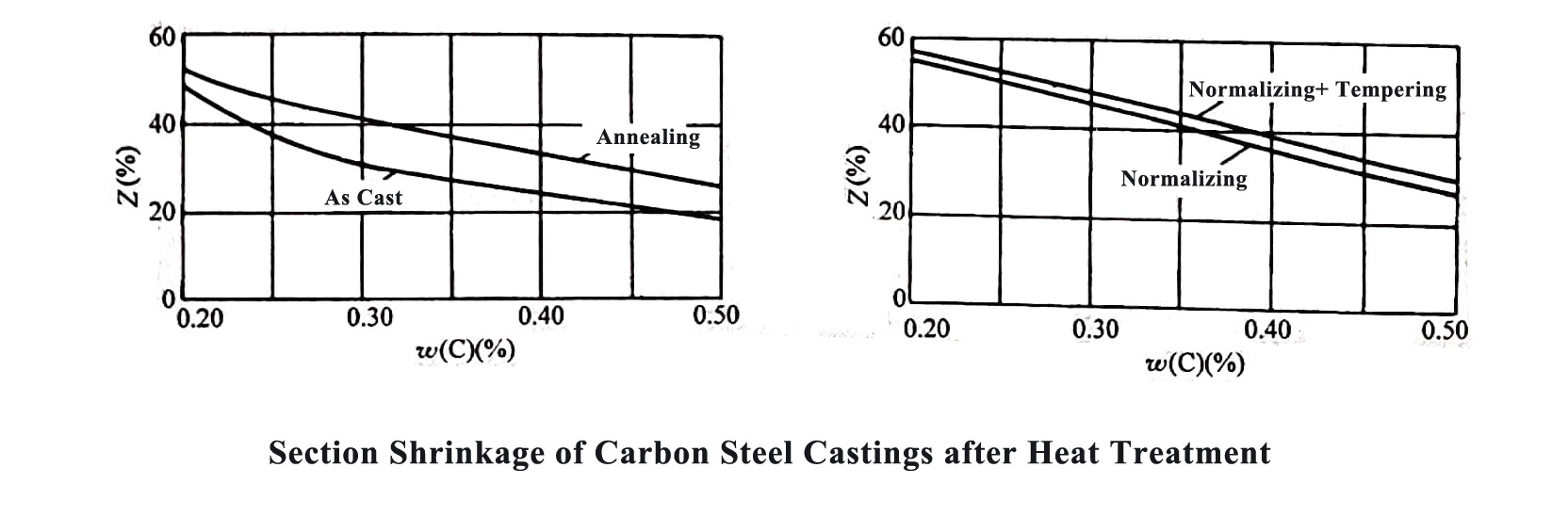

Iindlela zokunyanga ubushushu zihlala zisetyenziselwa ukuphoswa kwentsimbi yekhabhoni zezi: annealing, normalizing okanye normalizing + tempering. Impembelelo yezi ndlela zintathu zonyango lokushisa kwiipropati zemishini ye-carbon steel cast iboniswe kumzobo ongezantsi.

| Iqondo lobushushu eliAnealing kunye noBulukhuni beCarbon Steel Castings | ||||||

| IBanga leCarbon Steel | Umxholo weCarbon / % | Iqondo lobushushu elihonjisiweyo / ℃ | Ukubamba ixesha | Indlela yokupholisa | Ukuqina / HBW | |

| Ukutyeba kodonga / mm | Ixesha / h | |||||

| ZG200 - 400 | 0.10 - 0.20 | 910 - 880 | < 30 | 1 | Ukupholisa ukuya kuma-620℃ kwiziko kwaye emva koko kuphole emoyeni | 115 - 143 |

| ZG230 - 450 | 0.20 - 0.30 | 900 - 870 | 133 - 156 | |||

| ZG270 - 500 | 0.30 - 0.40 | 890 - 860 | 143 - 187 | |||

| ZG310 - 570 | 0.40 - 0.50 | 870 - 840 | 30 - 100 | ukwandisa iyure eyi-1 / 30 mm | 156 - 127 | |

| ZG340 - 640 | 0.50 - 0.60 | 860 - 830 | 187 - 230 | |||

Iipropathi zoomatshini zentsimbi yentsimbi eqhelekileyo ziphezulu kancinane kunezo zentsimbi ephosiweyo. Njengoko iqondo le-undercooling ngexesha lokuguqulwa kwesakhiwo likhulu kakhulu, ubunzima buya kuba buphezulu, kwaye ukusebenza kwayo kokusika kungcono.

| UkuQiniswa kunye noBulukhuni beCarbon Steel Castings | |||||

| IBanga leCarbon Steel | Umxholo weCarbon (%) | Ubushushu obuqhelekileyo / ℃ | Ukufudumeza | Ukuqina / HBW | |

| Ubushushu / ℃ | Indlela yokupholisa | ||||

| ZG200 - 400 | 0.10 - 0.20 | 930 - 890 | 540 - 610 | eziko okanye emoyeni | 126 - 149 |

| ZG230 - 450 | 0.20 - 0.30 | 930 - 890 | 540 - 610 | eziko okanye emoyeni | 139 - 169 |

| ZG270 - 500 | 0.30 - 0.40 | 890 - 860 | 550 - 620 | eziko okanye emoyeni | 149 - 187 |

| ZG310 - 570 | 0.40 - 0.50 | 890 - 850 | 550 - 650 | eziko okanye emoyeni | 163 - 217 |

| ZG340 - 640 | 0.50 - 0.60 | 870 - 830 | 550 - 650 | eziko okanye emoyeni | 187 - 228 |

Kwi-carbon steel castings enomxholo ophezulu wekhabhoni kunye neemilo eziyinkimbinkimbi, ukwenzela ukuphelisa uxinzelelo olushiyekileyo kunye nokuphucula ukuqina, unyango oluvuthayo lunokwenziwa emva kokuqhelekileyo. Ubushushu bobushushu buqhele ukuba yi-550℃-650℃, kwaye emva koko buphole emoyeni.

Xa umxholo wekhabhoni uphezulu kune-0.35%, iindawo zentsimbi zekhabhoni nazo ziyakwazi ukucinywa kwaye zihluthwe (zicinywe + ukushisa okuphezulu). I-carbon steel castings encinci inokucinywa ngokuthe ngqo kwaye ihlanjululwe kwimeko ye-as-cast; ezinkulu okanye ezintsonkothileyo-ezimile carbon steel castings kufuneka zicinywe kwaye inomsindo emva kokuqheleka.

| Ukucinywa kunye noBubushushu boBubushushu kunye noBulukhuni beCarbon Steel Castings | |||

| Umxholo weCarbon % | Ukucima Ubushushu / ℃ | Ubushushu bobushushu / ℃ | Ukuqina emva kokucaphuka / HBW |

| 0.35 - 0.45 (Iqela elincinci) | 850 - 830 (Ukupholisa emanzini) | 300 - 400 | 364 - 444 |

| 400 - 450 | 321 - 415 | ||

| 510 - 550 | 241 - 286 | ||

| 540 - 580 | 228 - 269 | ||

| 580 - 640 | 192 - 228 | ||

| 0.45 - 0.55 (Iqela elincinci) | 830 - 810 (Ukupholisa emanzini okanye kwi-oyile) | 550 - 630 | 220 - 240 |

| 450 | ≈ 269 | ||

| 550 | ≈ 248 | ||

| 650 | ≈ 228 | ||

| 0.30 - 0.40 (Iqela leMisa) | 840 -880 (Ukupholisa emanzini okanye kwi-oyile) | 520 - 550 | 229 - 269 |

| 530 - 560 | 217 - 255 | ||

| 540 - 570 | 207 - 241 | ||

| 550 - 580 | 187 - 229 | ||

| 0.40 - 0.50 (Iqela lobunzima) | 820 - 840 (Ukupholisa emanzini okanye kwi-oyile) | 530 - 560 | 229 - 269 |

| 550 - 580 | 217 - 255 | ||

| 560 - 590 | 207 - 241 | ||

| 570 - 600 | 187 - 229 | ||

Ixesha lokuposa: Jul-23-2021