eTshayinaUmboneleli weenkonzo zomatshini we-CNCukuba nentsimbi engatyiwa ngoomatshini ngokwemizobo yakho kunye neemfuno, ezisetyenziselwa ukumpompa izindlu kunye nomzimba.

Umatshini we-CNC ubhekisa kwinkqubo yomatshini eqhutywa yiComputerized Numberical Control (CNC ngamafutshane). Incediswa yi-CNC ukufikelela ukuchaneka okuphezulu kunye nokuzinzileyo kunye neendleko eziphantsi zabasebenzi. Machining naziphi na iinkqubo ezahlukeneyo apho isiqwenga semathiriyeli ekrwada sisikwa kwimilo enqwenelekayo yokugqibela kunye nobukhulu ngenkqubo elawulwayo yokususwa kwezinto. Iinkqubo ezinomxholo oqhelekileyo, ukususwa kwezinto ezilawulwayo, namhlanje ziyaziwa ngokudibeneyo njengemveliso ekhuphayo, ngokwahlukileyo kwiinkqubo zokongezwa kwezinto ezilawulwayo, ezaziwa njengemveliso yokongeza.

Ngokuchanekileyo oko kuthetha ukuba inxalenye "elawulwayo" yenkcazo inokwahluka, kodwa isoloko ithetha ukusetyenziswa kwezixhobo zoomatshini (ukongeza nje izixhobo zamandla kunye nezixhobo zesandla). Le yinkqubo esetyenziselwa ukwenza iimveliso ezininzi zentsimbi, kodwa inokusetyenziswa kwizinto ezifana nemithi, iplastiki, i-ceramic, kunye ne-composites. I-CNC machining ibandakanya iinkqubo ezininzi ezahlukeneyo ezifana nokusila, ukujika, ukubethelwa kwentambo, ukugrumba, ukuhombisa, ukugaya ... njl.

| CNC Precision Machining Izakhono | ||||

| Izibonelelo | Ubungakanani | Ubungakanani Uluhlu | Amandla oNyaka | Ukuchaneka ngokubanzi |

| Iziko loMatshini elithe nkqo (VMC) | 48 iiseti | 1500mm × 1000mm × 800mm | 6000 tonn okanye 300000 amaqhekeza | ±0.005 |

| Iziko loMatshini elithe tye (VMC) | 12 iiseti | 1200mm × 800mm × 600mm | 2000 iitoni okanye 100000 amaqhekeza | ±0.005 |

| Umatshini weCNC | 60 iiseti | UMax ujika idia. φ600mm | Iitoni ezingama-5000 okanye iziqwenga ezingama-600000 | |

| Umgangatho oPhezulu wokuPhathwa koNyamezelo: ISO 8062 2013, ISO 2768, GOST 26645 (Russia) okanye GBT 6414 (China). | ||||

Iziko lomatshini liphuhliswa kumatshini wokusila we-CNC. Umahluko omkhulu kumatshini wokugaya we-CNC kukuba iziko lomatshini linamandla okutshintsha ngokuzenzekelayo izixhobo zomatshini. Ngokufakela izixhobo ngeenjongo ezahlukeneyo kwimagazini yesixhobo, izixhobo zobuchwephesha kwi-spindle zinokutshintshwa sisiguquli sesixhobo esizenzekelayo kwi-clamping enye ukuqonda iimpawu ezininzi zomatshini.

Iziko lomatshini we-CNC sisixhobo somatshini esisebenza ngokufanelekileyo esinezixhobo zoomatshini kunye nenkqubo ye-CNC kwaye ifanelekile ukusetyenzwa kwamacandelo anzima. Iziko lomatshini le-CNC okwangoku sesinye sezona zixhobo zisetyenziswa kakhulu kumatshini we-CNC kwihlabathi elinamandla okusebenza abanzi. Iyakwazi ukugqiba umxholo wokuqhubela phambili emva kokuba i-workpiece ibanjwe ngexesha elinye. Ukuchaneka kokucubungula kuphezulu. Kwizinto zokusebenza zebhetshi ezinobunzima bokucubungula okuphakathi, ukusebenza kakuhle kwayo kumaxesha angama-5-10 kunesixhobo esiqhelekileyo, ngakumbi kunokugqiba Uninzi lweeprosesa ezingenakugqitywa zizixhobo eziqhelekileyo zilungele ngakumbi ukusetyenzwa kweqhekeza elinye kunye neemilo ezintsonkothileyo kunye neemfuno ezichanekileyo okanye ezichanekileyo. kwimveliso yebhetshi encinci naphakathi yeentlobo ezininzi. Igxininisa imisebenzi yokugaya, ukudika, ukubhola, ukucofa kunye nokusika intambo kwisixhobo esinye, ukuze ube neendlela ezahlukeneyo zobuchwepheshe.

Amaziko omatshini ahlelwa ngamaziko omatshini athe tye nathe nkqo ngokwendawo yawo yesithuba ngexesha lomatshini wokusonta. Ihlelwa ngokwenkqubo yokusetyenziswa: iziko lomatshini elikruqulayo kunye nelokusila, iziko lomatshini elidityanisiweyo. Ngokohlelo olukhethekileyo lwemisebenzi, kukho: i-workbench eyodwa, i-workbench ephindwe kabini kunye neziko lomatshini we-multi-workbench. Amaziko omatshini ane-single-axis, i-double-axis, i-axis emithathu, i-axis emine, i-five-axis kunye ne-headstocks eguquguqukayo, njl.

I-CNC machining luhlobo lomatshini oluchanekileyo ngoomatshini be-CNC abafana namaziko omatshini aphezulu anesiphelo esiphezulu se-5 axis machining center, i-4 axis double platform machining center, okanye i-CNC turning lathes enokuthi iphuhliswe kwiziko lokujika le-CNC elinamandla okutshintsha ngakumbi. ngaphezu kwe-15 cutters ngaphakathi kwishifti enye yokubamba; Umatshini wokugaya i-CNC kunye ne-CNC yokugaya kunye nokucofa amaziko.Ukuchaneka kwe-machining ye-steel casting kuhluke kwi-machining yeprofayili yensimbi. Ukuphosa okuchanekileyo sele kufikelele kwimilo echanekileyo yento oyifunayo, kungoko igcina oomatshini abaninzi xa kuthelekiswa nomatshini osuka kwiprofayile yentsimbi ngokuthe ngqo. Kananjalo ngenxa yesi sizathu, ngokwesiqhelo kufuneka siqwalasele umphezulu womatshini kunye nesibonelelo esifanelekileyo somatshini ngaphambi kokuphosa. Ukuthenga kwethu rhoqo kukwenza umzobo okrwada kunye nomzobo womatshini ukucacisa indawo yomatshini kunye nesibonelelo somatshini kumzobo.

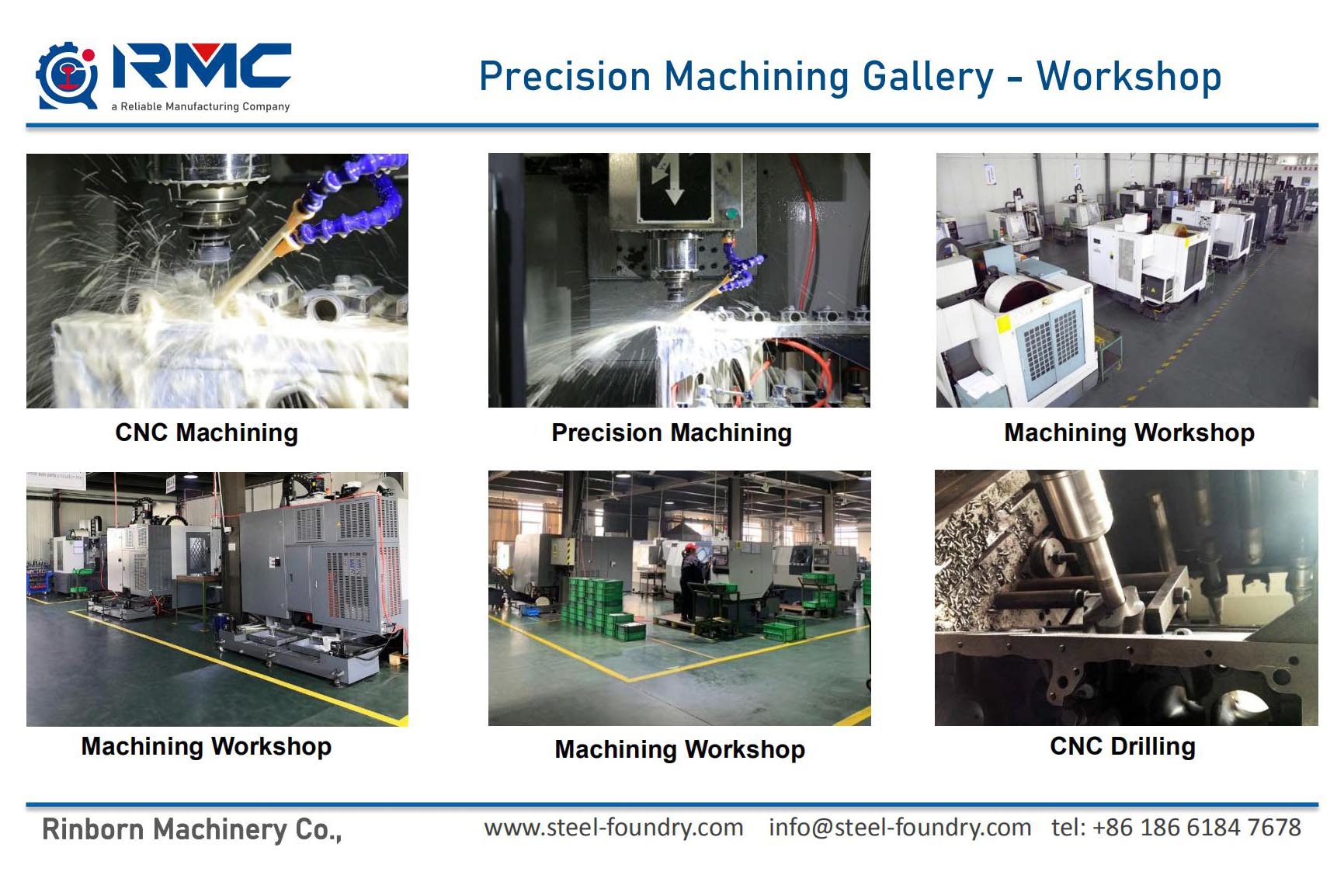

Isiseko sotyalo-mali se-RMC sixhotyiswe ngamaziko ama-4 e-axis machining, iiseti ezili-15 ze-CNC zokuguqula iileyile kunye neeseti ezi-3 zoomatshini bokusila be-cnc, kunye nomncedisi oqhelekileyo wokujika, ukugaya, ukucofa, ukubhola kunye noomatshini bokusila, sinamandla okwenza oomatshini phantse bonke. iintlobo zentsimbi.

| IBanga eliLinganayo leNtsimbi yeCast Alloy evela kwiiMarike ezohlukeneyo | |||||||||

| AMAQELA | AISI | I-W-stoff | I-DIN | BS | SS | UKUBALULEKILE | UNE / IHA | I-JIS | I-UNI |

| Intsimbi ye-Alloy ephantsi | 9255 | 1.0904 | 55 iSi 7 | 250 A53 | 2090 | 55 S7 | 56Si7 | - | 5SSi8 |

| 1335 | 1.1167 | 36 Mn 5 | 150 M 36 | 2120 | 40 M5 | 36Mn5 | I-SMn 438(H) | - | |

| 1330 | 1.1170 | 28 mz6 | 150 M 28 | - | 20 M5 | - | SCMn1 | C28MN | |

| P4 | 1.2341 | X6 CrMo 4 | - | - | - | - | - | - | |

| 52100 | 1.3505 | 100 Kr 6 | 534 A99 | 2258 | 100 C 6 | F.131 | SUJ 2 | 100Cr6 | |

| A204A | 1.5415 | 15 Mo 3 | 1501 240 | 2912 | 15 D 3 | 16 Mo3 | I-STBA 12 | 16Mo3 KW | |

| 8620 | 1.6523 | 21 NiCrMo 2 | 805 M 20 | 2506 | 20 NCD 2 | F.1522 | I-SNCM 220(H) | 20NiCrMo2 | |

| 8740 | 1.6546 | 40NiCrMo22 | 311-Udidi 7 | - | 40 NCD 2 | F.129 | I-SNCM 240 | 40NiCrMo2(KB) | |

| - | 1.6587 | 17CrNiMo6 | 820 A16 | - | 18 NCD 6 | 14NiCrMo13 | - | - | |

| 5132 | 1.7033 | 34 Kr4 | 530 A32 | - | 32 C 4 | 35Cr4 | I-SCr430(H) | 34Cr4(KB) | |

| 5140 | 1.7035 | 41 Kr4 | 530 A40 | - | 42 C 2 | 42 Kr4 | I-SCr 440 (H) | 40Cr4 | |

| 5140 | 1.7035 | 41 Kr4 | 530 A40 | - | 42 C 2 | 42 Kr4 | I-SCr 440 (H) | 41Cr4 KB | |

| 5140 | 1.7045 | 42 Kr4 | 530 A40 | 2245 | 42 C 4 TS | F.1207 | I-SCr 440 | - | |

| 5115 | 1.7131 | 16 MnCr 5 | (527 M 20) | 2511 | 16 MC 5 | F.1516 | - | 16MnCr5 | |

| 5155 | 1.7176 | 55 Kr3 | 527 A60 | 2253 | 55 C 3 | - | SUP 9(A) | 55Cr3 | |

| 4130 | 1.7218 | 25 CrMo 4 | 1717CDS 110 | 2225 | 25 CD 4 | F.1251/55Cr3 | I-SCM 420 / SCM430 | 25CrMo4(KB) | |

| 4135 (4137) | 1.7220 | 35 CrMo 4 | 708 A37 | 2234 | 35 CD 4 | 34 CrMo 4 | SCM 432 | 34CrMo4KB | |

| 4142 | 1.7223 | 41 CrMo 4 | 708 M 40 | 2244 | 42 CD 4 TS | 42 CrMo 4 | SCM 440 | 41 CrMo 4 | |

| 4140 | 1.7225 | 42 CrMo 4 | 708 M 40 | 2244 | 40 CD 4 | F.1252 | SCM 440 | 40CrMo4 | |

| 4137 | 1.7225 | 42 CrMo 4 | 708 M 40 | 2244 | 42 CD 4 | F.1252 | SCM 440 | 42CrMo4 | |

| A387 12-2 | 1.7337 | 16 CrMo 4 4 | 1501 620 | 2216 | 15 CD 4.5 | - | - | 12CrMo910 | |

| - | 1.7361 | 32CrMo12 | 722 M 24 | 2240 | 30 CD 12 | F.124.A | - | 30CrMo12 | |

| A182 F-22 | 1.7380 | 10 CrMo9 10 | 1501 622 | 2218 | 12 CD 9, 10 | F.155 / TU.H | - | 12CrMo9 10 | |

| 6150 | 1.8159 | 50 CrV 4 | 735 A50 | 2230 | 50 iCV 4 | F.143 | SUP 10 | 50CrV4 | |

| - | 1.8515 | 31 CrMo 12 | 722 M 24 | 2240 | 30 CD 12 | F.1712 | - | 30CrMo12 | |

| - | - | - | - | - | - | - | - | - | |

| Intsimbi ye-Alloy ephakathi | W1 | 1.1545 | C105W1 | BW1A | 1880 | Y 105 | F.5118 | SK 3 | C100 KU |

| L3 | 1.2067 | 100Cr6 | BL 3 | (2140) | Y 100 C 6 | F.520 L | - | - | |

| L2 | 1.2210 | 115 CrV 3 | - | - | - | - | - | - | |

| P20 + S | 1.2312 | 40 CrMnMoS 8 6 | - | - | 40 CMD 8 +S | X210CrW12 | - | - | |

| - | 1.2419 | 105WCr6 | - | 2140 | 105W C 13 | F.5233 | SKS 31 | 107WCr5KU | |

| O1 | 1.2510 | 100 MnCrW 4 | BO1 | - | 90MnWCRV5 | F.5220 | (SK53) | 95MnWCr5KU | |

| S1 | 1.2542 | 45 WCrV 7 | BS1 | 2710 | 55W20 | F.5241 | - | 45WCrV8KU | |

| 4340 | 1.6582 | 34 CrNiMo 6 | 817 M 40 | 2541 | 35 NCD 6 | F.1280 | I-SNCM 447 | 35NiCrMo6KB | |

| 5120 | 1.7147 | 20 MnCr 5 | - | - | 20 MC 5 | - | - | - | |

| - | - | - | - | - | - | - | - | - | |

| Isixhobo kunye ne-High Alloy Steel | D3 | 1.2080 | X210 Cr 12 | BD3 | 2710 | Z200 C 12 | F.5212 | SKD 1 | X210Cr13KU |

| P20 | 1.2311 | 40 CrMnMo 7 | - | - | 40 CMD 8 | F.5263 | - | - | |

| H13 | 1.2344 | X40CrMoV 5 1 | BH13 | 2242 | Z 40 CDV 5 | F.5318 | SKD 61 | X40CrMoV511KU | |

| A2 | 1.2363 | X100 CrMoV 5 1 | BA2 | 2260 | Z 100 CDV 5 | F.5227 | SKD 12 | X100CrMoV51KU | |

| D2 | 1.2379 | X155 CrMoV 12 1 | BD2 | 2310 | Z 160 CDV 12 | F.520.A | SKD11 | X155CrVMo121KU | |

| I-D4 (D6) | 1.2436 | X210 CrW 12 | BD6 | 2312 | Z 200 CD 12 | F.5213 | SKD 2 | X215CrW121KU | |

| H21 | 1.2581 | X30WCrV9 3 | BH21 | - | Z 30 WCV 9 | F.526 | SKD5 | X30WCrV 9 3 KU | |

| L6 | 1.2713 | 55NiCrMoV 6 | - | - | 55 NCDV 7 | F.520.S | SKT4 | - | |

| M 35 | 1.3243 | S6/5/2/5 | BM 35 | 2723 | 6-5-2-5 | F.5613 | SKH 55 | HS6-5-5 | |

| M2 | 1.3343 | S6/5/2 | BM2 | 2722 | Z 85 WDCV | F.5603 | SKH 51 | HS6-5-2-2 | |

| M 7 | 1.3348 | S2/9/2 | - | 2782 | 2 92 | - | - | HS2-9-2 | |

| HW 3 | 1.4718 | X45CrSi 9 3 | 401 S 45 | - | Z 45 CS 9 | F.3220 | SUH1 | X45CrSi8 | |

| - | 1.7321 | 20 MoCr 4 | - | 2625 | - | F.1523 | - | 30CrMo4 | |

| Intsimbi yokuqina okuphakamileyo | I-A128 (A) | 1.3401 | G-X120 Mn 12 | BW10 | 2183 | Z 120 M 12 | F.8251 | SCMnH 1 | I-GX120Mn12 |

Ubunakho beInvestment Casting Foundry:

• Ubungakanani obukhulu: 1,000 mm × 800 mm × 500 mm

• Ubunzima Uluhlu: 0.5 kg - 100 kg

• Umthamo woNyaka: iitoni ezingama-2,000

• IiMathiriyeli zeBond kwiSakhiwo seShell: ISilica Sol, iglasi yamanzi kunye nemixube yazo.

• Unyamezelo: Ngesicelo.

Izinto ezilungileyo zeAmacandelo oTyalo mali:

-Umgangatho ogqwesileyo kwaye ugudileyo

- Ukunyamezela okuqinileyo.

- Iimilo ezintsonkothileyo nezintsonkothileyo ezinokuguquguquka koyilo

- Ukukwazi ukuphosa iindonga ezincinci ngoko ke icandelo lokuphosa elilula

-Ukhetho olubanzi lwesinyithi kunye ne-alloys (i-ferrous kunye ne-non-ferrous)

- Uyilo alufunwa kuyilo lokungunda.

- Ukunciphisa imfuno yomatshini yesibini.

- Inkunkuma yezinto eziphantsi.

| Izixhobo zoTyalo-mali lokuCasa kunyeCNC Machiningkwi-RMC Foundry | |||

| Udidi | China iBanga | IBanga lase-US | IBanga laseJamani |

| Intsimbi yentsimbi yeFerritic | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Intsimbi yentsimbi yeMartensitic | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Austenitic steel stainless | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.44404, 9, 1.4404, 9 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Imvula Ukwenza lukhuni intsimbi engatyiwayo | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex Steel engatyiwa | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| High Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Isixhobo sentsimbi | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Intsimbi ekwaziyo ukumelana nobushushu | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| I-Nickle-base Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOLOY600, I-INKOLOY625 | 2.4815, 2.4879, 2.4680 | |

| Aluminiyam Ingxubevange | ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | I-G-AlSi7Mg, i-G-Al12 |

| Ingxubevange yobhedu | H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| I-Cobalt-base Alloy | UMC50, 670, Grade 31 | 2.4778 | |

Ekwabizwa ngokuba ngoomatshini bokuchaneka, umatshini we-CNC unokufikelela kukuchaneka okuphezulu kakhulu kunyamezelo lwe-geometical kunye nokunyamezelana komda. Ngoomatshini bethu be-CNC kunye namaZiko okuMachiza okuNxweme (HMC) kunye namaZiko oMatshini aNqobileyo (VMC), sinokuphantse sihlangabezane nawo onke amabakala akho afunekayo okunyamezela.

| UKUNYAMEZELA UKULAHLWA KOTYALO-MALI | |||

| I-intshi | Iimilimitha | ||

| Ubungakanani | Ukunyamezelana | Ubungakanani | Ukunyamezelana |

| Ukuya kuthi ga kwi-0.500 | ±.004" | Ukuya kuthi ga kwi-12.0 | ± 0.10mm |

| 0.500 ukuya kwi-1.000" | ±.006" | 12.0 ukuba 25.0 | ± 0.15mm |

| 1.000 ukuya 1.500” | ±.008" | 25.0 ukuba 37.0 | ± 0.20mm |

| 1.500 ukuya ku-2.000” | ±.010" | 37.0 ukuba 50.0 | ± 0.25mm |

| 2.000 ukuya 2.500” | ±.012" | 50.0 ukuba 62.0 | ± 0.30mm |

| 2.500 ukuya 3.500” | ±.014" | 62.0 ukuba 87.0 | ± 0.35mm |

| 3.500 ukuya ku-5.000" | ±.017" | 87.0 ukuba 125.0 | ± 0.40mm |

| 5.000 ukuya 7.500” | ±.020" | 125.0 ukuya ku-190.0 | ± 0.50mm |

| 7.500 ukuya 10.000” | ±.022" | 190.0 ukuba 250.0 | ± 0.57mm |

| 10.000 ukuya kwi-12.500" | ±.025" | 250.0 ukuba 312.0 | ± 0.60mm |

| 12.500 ukuba 15.000 | ±.028" | 312.0 ukuba 375.0 | ± 0.70mm |